Red punching on-line trimming mechanism

A technology of trimming and red punching, which is applied in mechanical equipment, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problems of low degree of automation, time-consuming and laborious, and achieve the effect of improving production efficiency and increasing load-bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

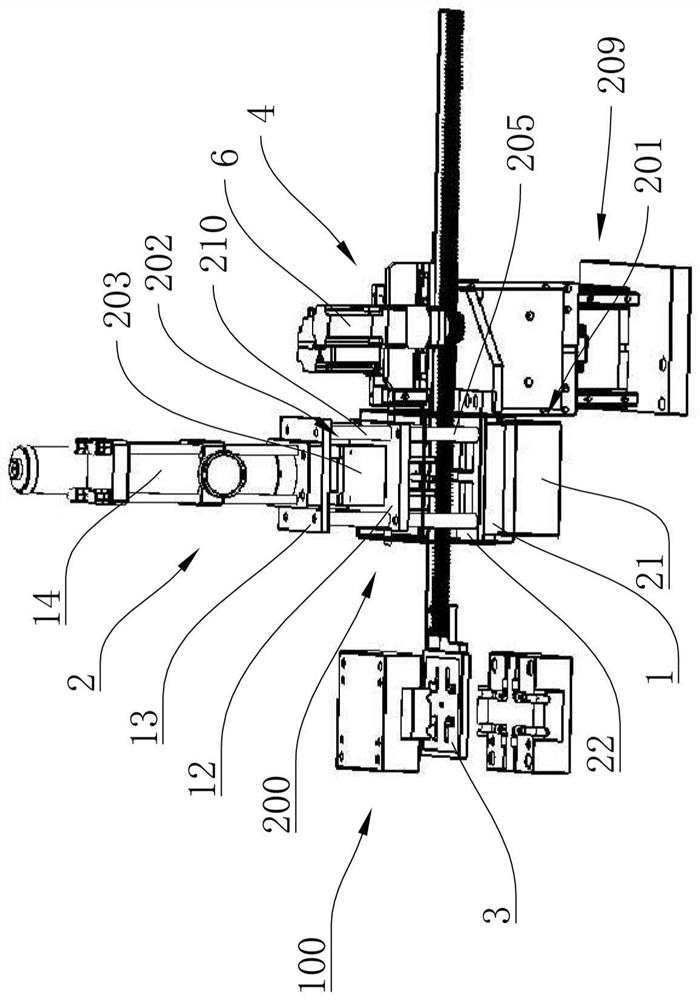

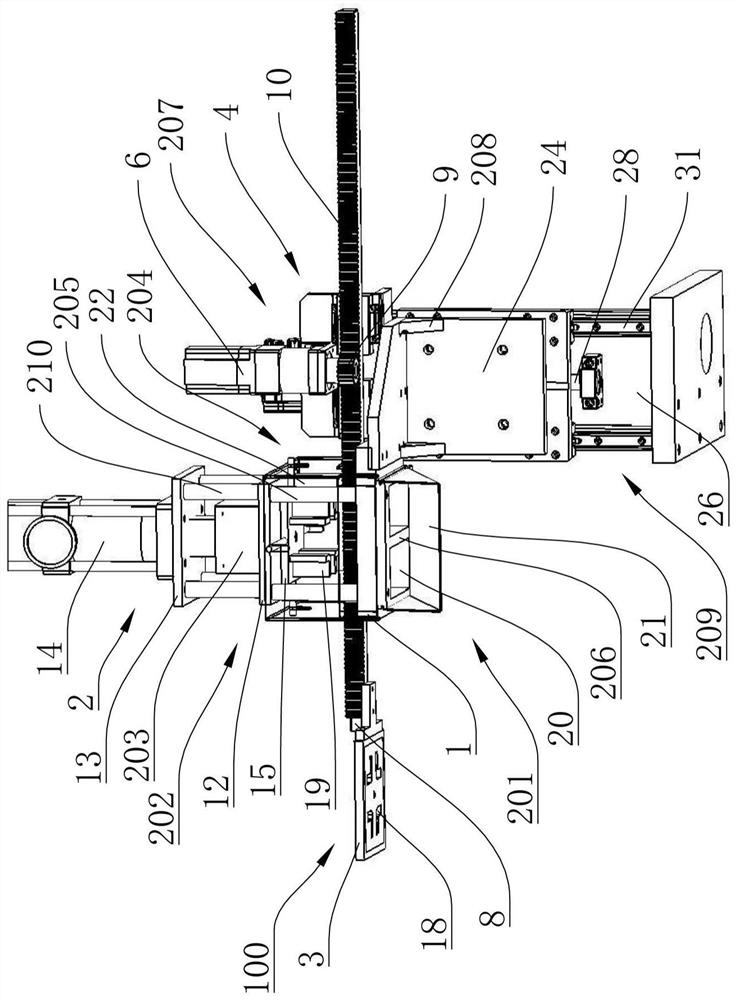

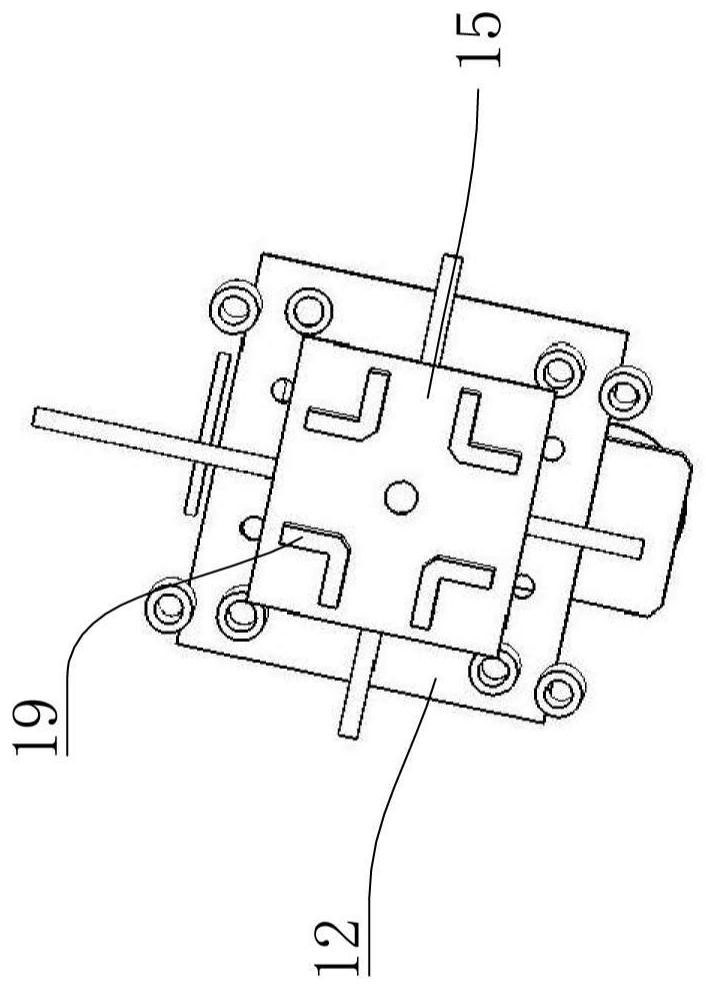

[0030] like figure 1 and figure 2 As shown, a red punching line trimming mechanism includes a frame 200, and a trimming mechanism seat 1 is arranged on the rack 200. The trimming mechanism seat 1 is provided with a forming area 100, and inside the forming area 100 A trimming mold 3 is provided, and the trimming mold 3 is provided with a trimming forming through groove 18 for trimming and shaping parts, and a trimming top mold 15 is arranged above the trimming mold 3, so The edge trimming top die 15 is connected with the vertical lifting mechanism 2, a discharging structure 201 is provided below the edge trimming die 3, and the edge trimming die 3 is connected with a device capable of driving the edge trimming die 3 to move out of the molding. The zone 100 carries out the traverse mechanism 4 for reclaiming.

[0031] In this embodiment, the red punch presses the product at the trimming die in the forming area and can shape the product to be trimmed at the edge trimming throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com