Lifting equipment capable of assisting in disassembling coal bunker lining plate

A technology of lifting equipment and lining boards, which is applied in the field of coal bunker lining boards, can solve problems such as the difficulty of dismantling the lining boards, and achieve the effect of reducing burden and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

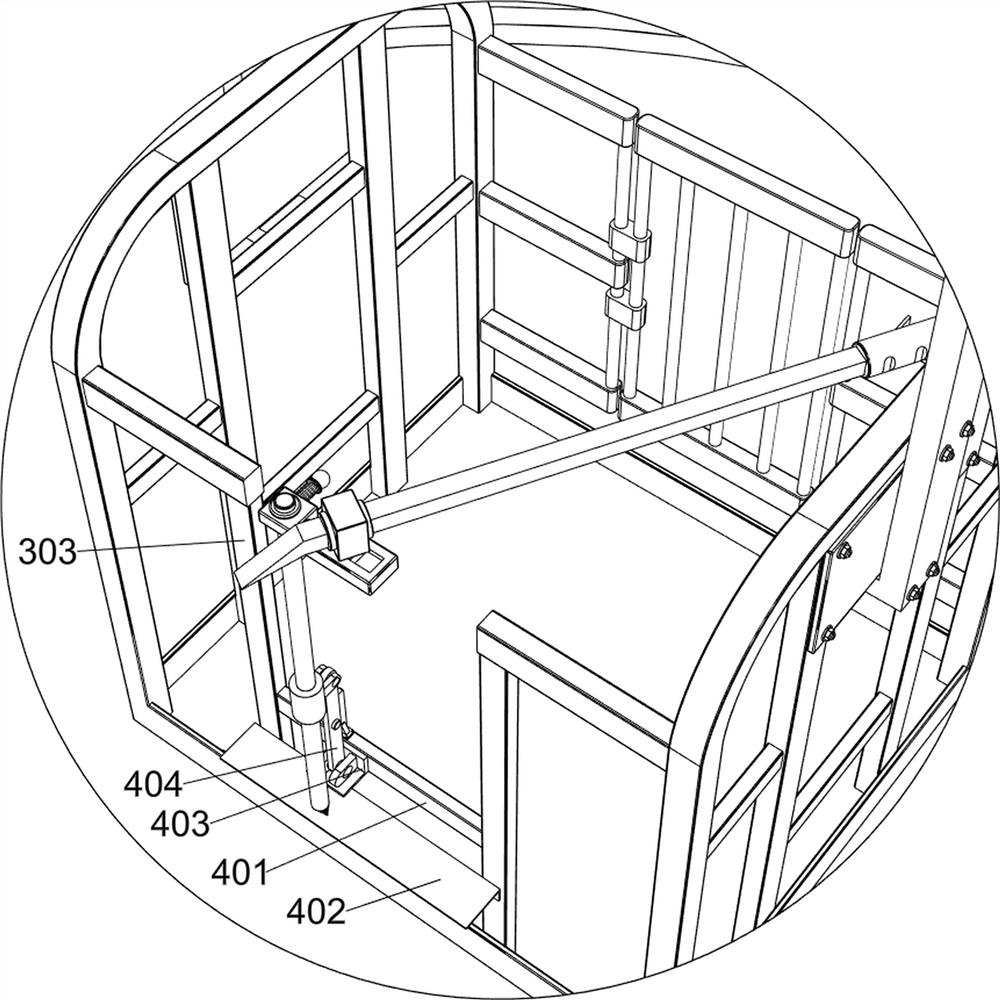

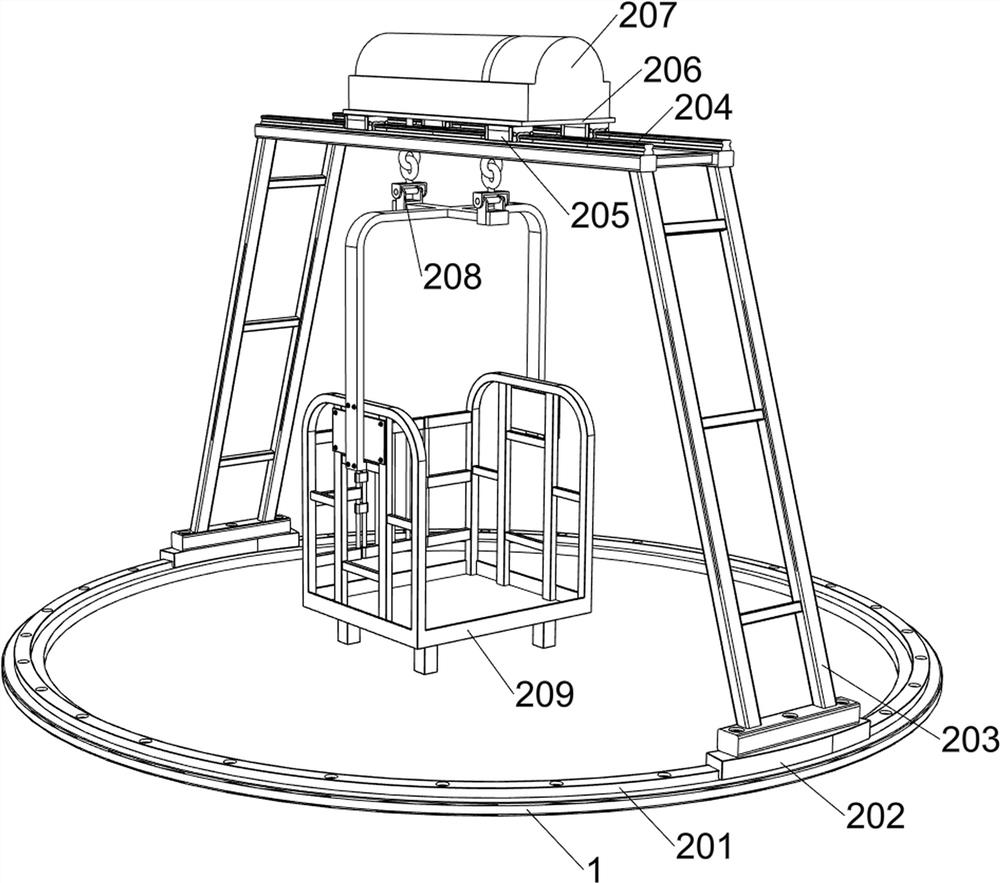

[0035] A lifting device that can assist in the removal of coal bunker linings, such as Figure 1-13 As shown, it includes an annular plate 1, a displacement system 2, a positioning system 3 and a disassembly system 4; the upper surface of the annular plate 1 is connected with a displacement system 2; the displacement system 2 is connected with two positioning systems 3, and the two positioning systems 3 Distributed symmetrically on the left and right; a disassembly system 4 is connected between the two positioning systems 3 ; the displacement system 2 is connected with the disassembly system 4 .

[0036] When in use, first place the lifting equipment that can assist in dismantling the coal bunker lining plate on the top of the coal bunker of the same size, place the annular plate 1 in a stable position, and first control the carrier in the displacement system 2 to descend to the inside of the coal bunker On the ground, the operator enters the carrier in the displacement system...

Embodiment 2

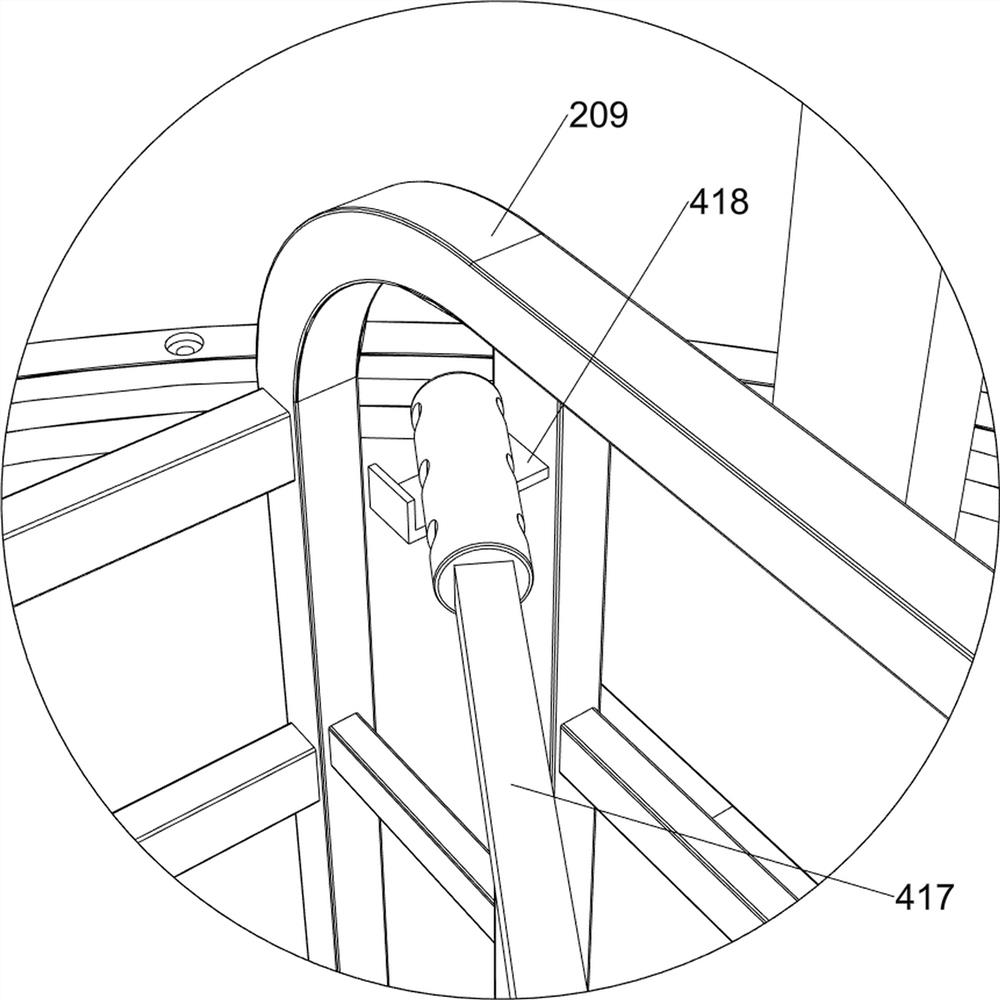

[0038] On the basis of Example 1, as Figure 1-13 As shown, the displacement system 2 includes an annular electric track 201 , a first electric slide 202 , a support frame 203 , an electric slide 204 , a second electric slide 205 , a mounting plate 206 , a hoist 207 , a connecting seat 208 and a protective frame 209 The upper surface of the annular plate 1 is bolted with an annular electric track 201; the front and rear of the outer surface of the annular electric track 201 are each slidably connected with a first electric slider 202; the upper surfaces of the two first electric sliders 202 are fixed A support frame 203 is connected; an electric slide rail 204 is connected with bolts on the left part of the upper surface of the support frame 203 and the right part of the upper surface; A mounting plate 206 is fixed on the upper surface of the four second electric sliding blocks 205; a hoist 207 is fixed on the upper surface of the mounting plate 206; A protective frame 209 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com