Calculation method and device for predicting shear fatigue life of modified asphalt with large mixing amount of rubber powder

A technology of modified asphalt and fatigue life, which is applied in the direction of testing material strength by applying stable shear force, complex mathematical operations, and testing material strength by applying repeated force/pulsation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

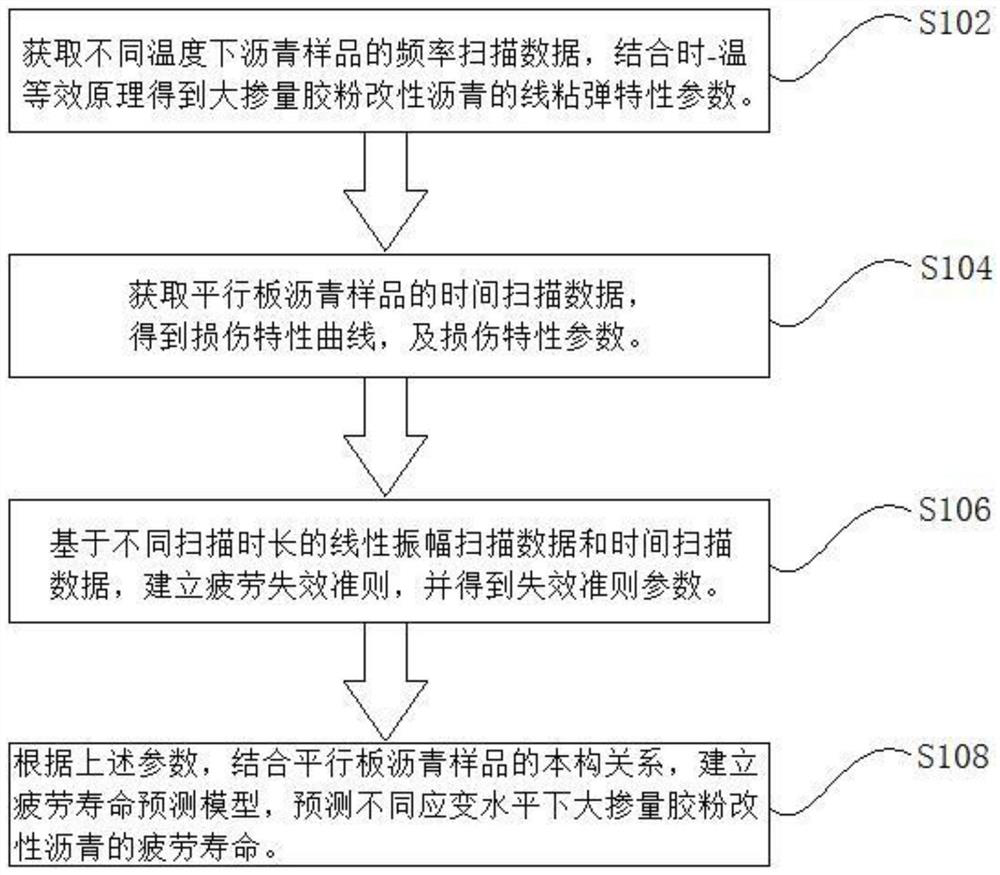

[0042]The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

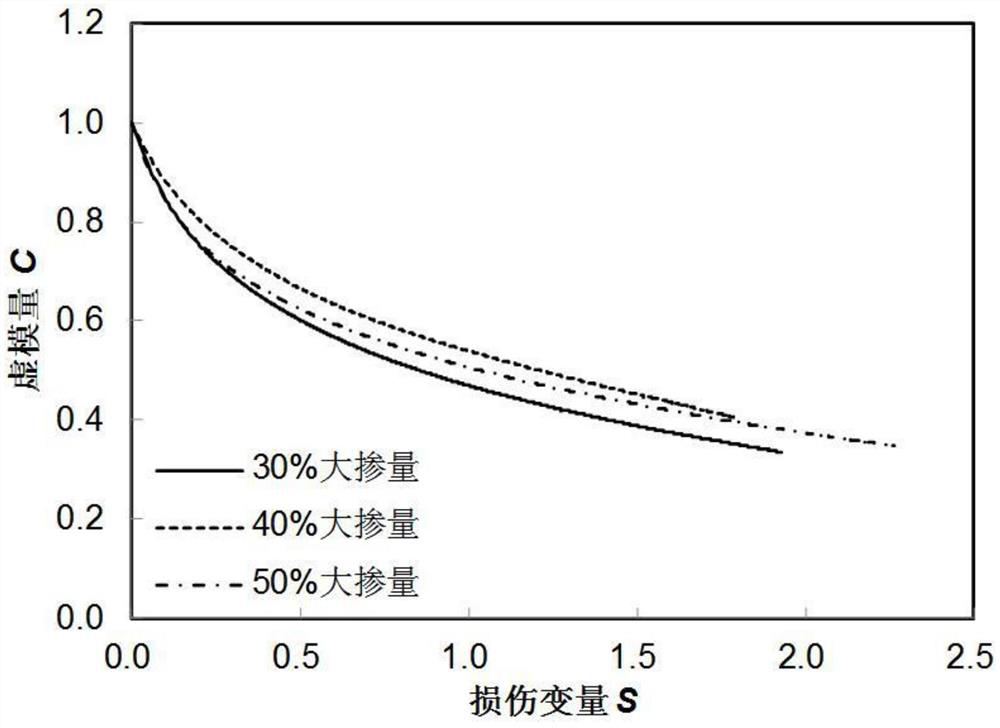

[0043] In this embodiment, frequency sweep data, linear amplitude sweep data, and time sweep data of parallel-plate asphalt samples at different temperatures, at different sweep times, and time need to be collected. In this embodiment, the specific method for obtaining the above data is as follows:

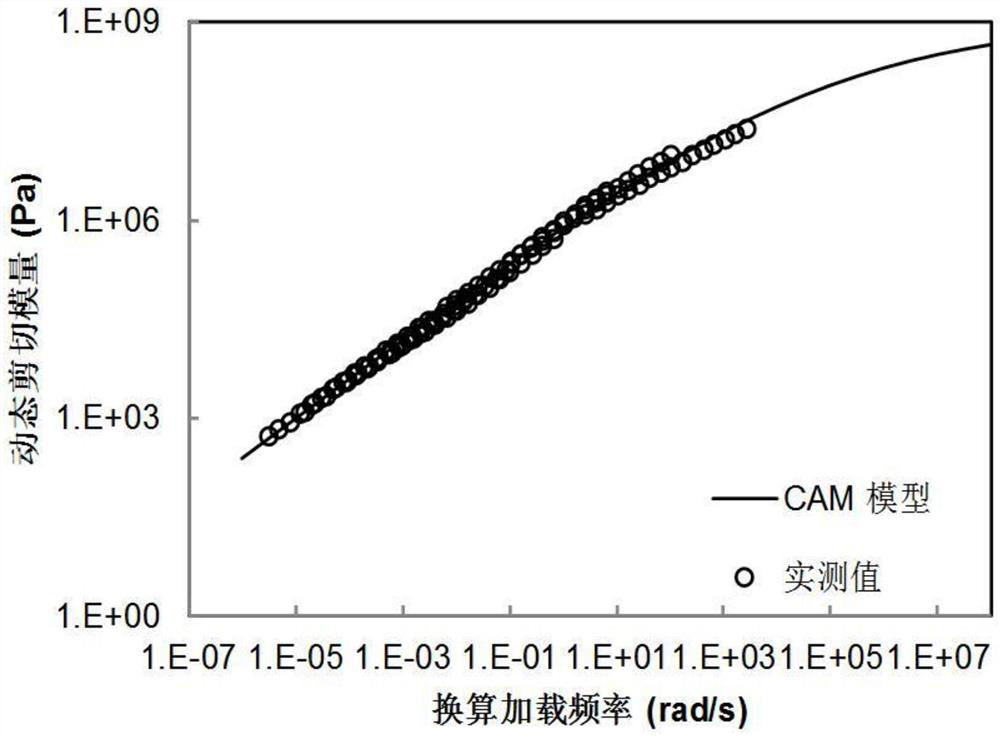

[0044] The dynamic shear rheometer was used to complete the frequency sweep test on the parallel-plate asphalt samples at 10°C, 20°C, 30°C, 40°C, 50°C, 60°C, and 70°C in turn to obtain frequency sweep data. The frequency sweep range was 0.1-100 rad / s and the strain level was 1%. Among them, the frequency sweep tests at 10°C, 20°C, and 30°C used parallel plates with a diameter of 8 m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap