Optical head feeder

A technology of feeding device and optical head, which is applied to the configuration/installation of the head, driving/moving the recording head, etc., which can solve problems such as difficulty and heavy weight of the optical head, and achieve the effect of increasing the rotation load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

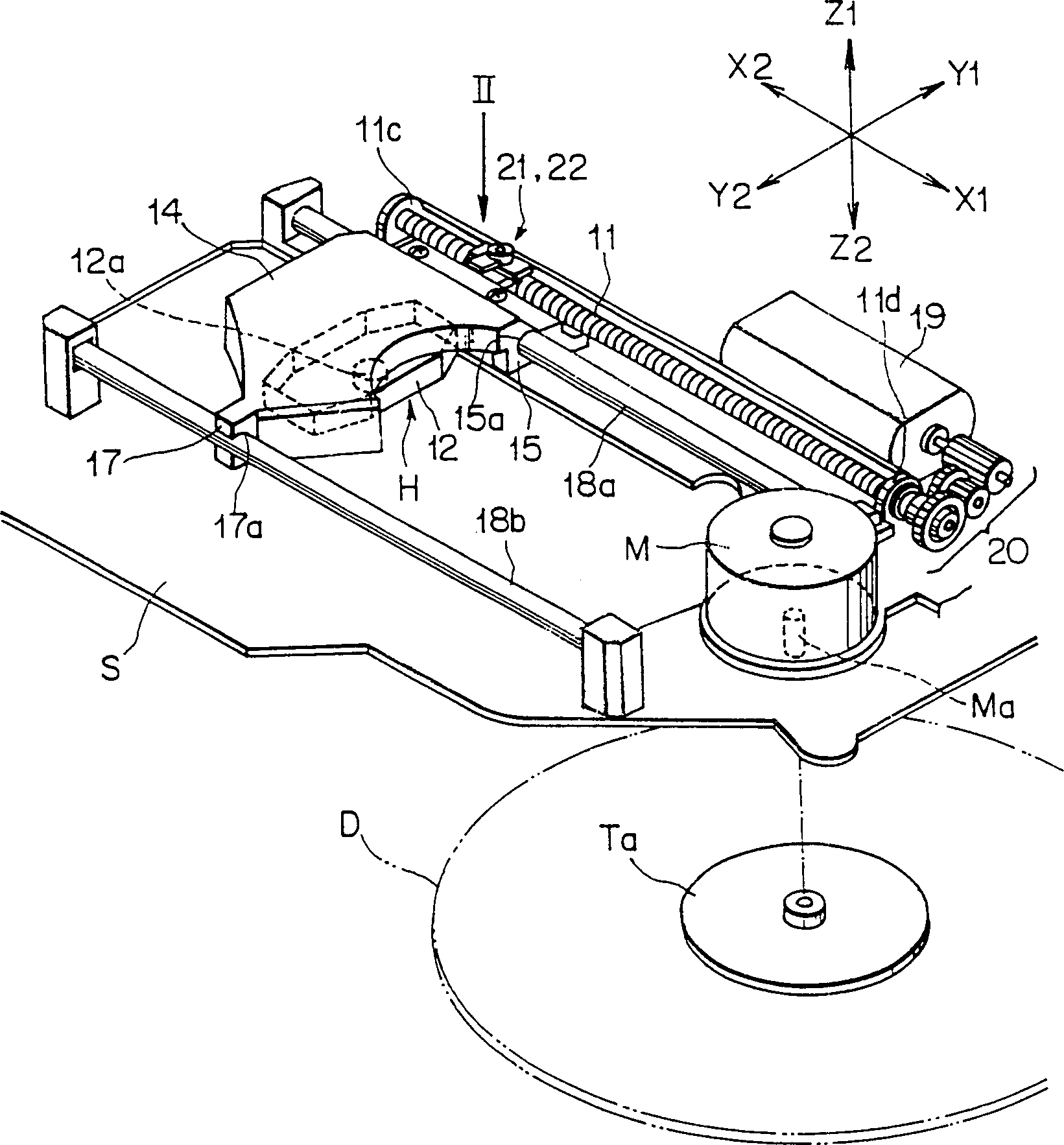

[0024] figure 1 It is a perspective view showing the whole of a disk drive unit for a digital video disk (DVD) with the optical head feeding device of the present invention mounted thereon facing upward. Such as figure 1 As shown, guide members (guide shafts) 18a, 18b are provided on the base plate S, and they are parallel to each other. The optical head unit H in which the optical head 12 is mounted is supported on the optical head base 14 between the guide members 18a, 18b. In the optical head 12, a light emitting element such as a semiconductor laser, an objective lens 12a, an element for receiving light, and other optical components are installed. The objective lens 12a collects the light emitted from the light-emitting element on the recording surface of the disc D, and the light-receiving element receives and detects the light reflected from the disc D.

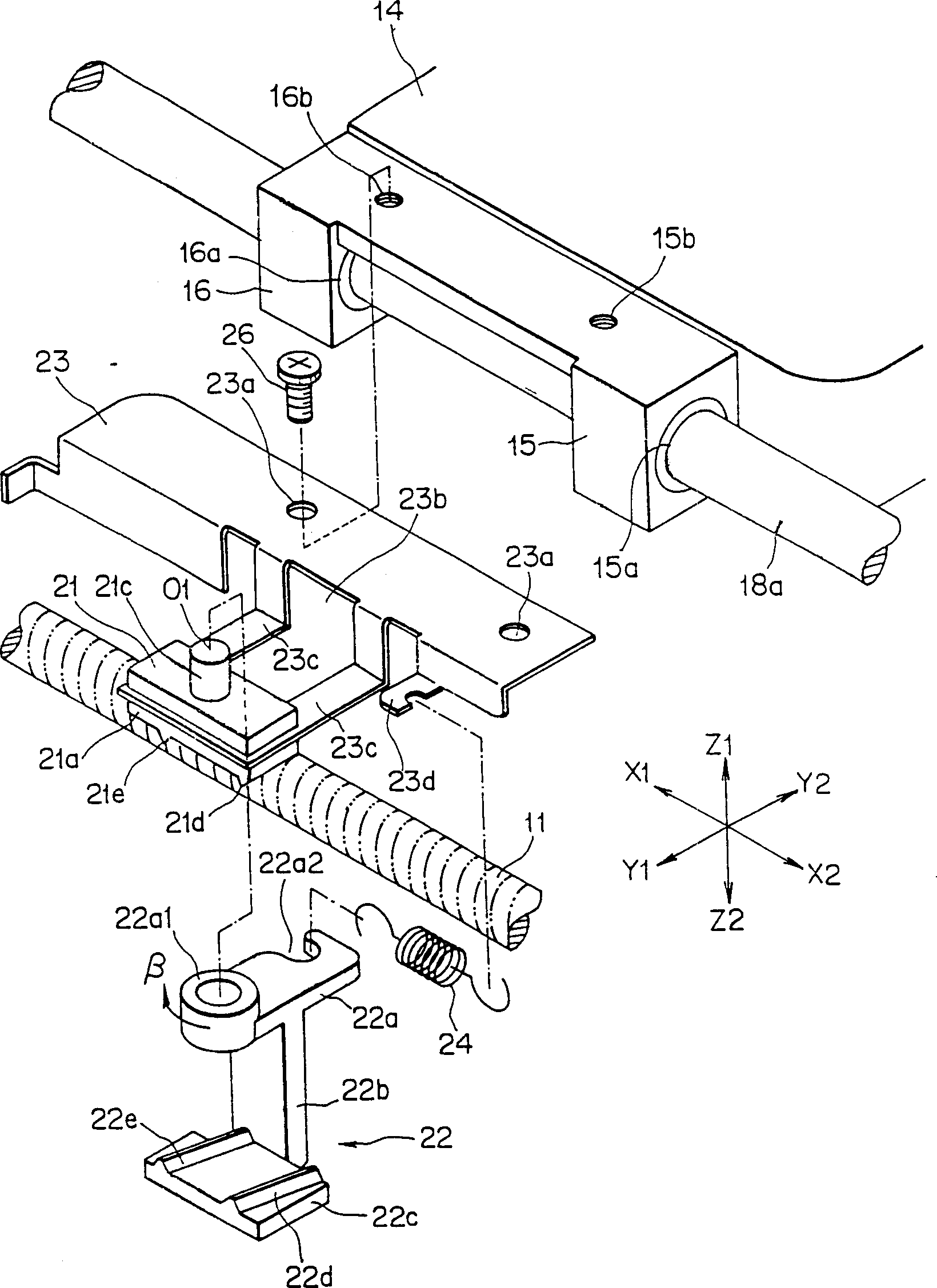

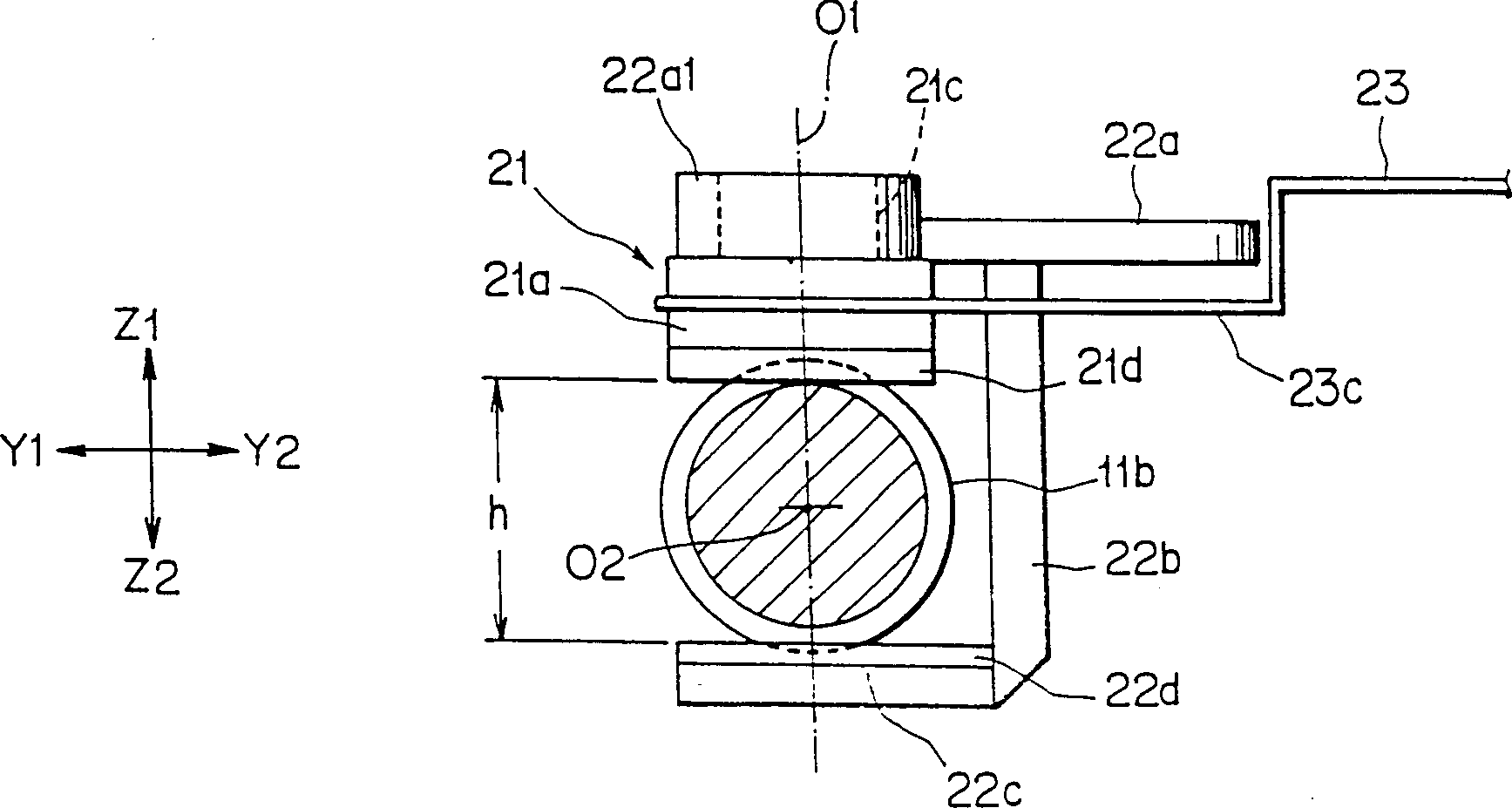

[0025] Bearing sleeves 15a, 16a are embedded in bearing portions 15, 16 integrally made on one side of the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com