Preparation device and preparation method of water-based anti-corrosion steel structure paint

A technology for preparing devices and steel structures, applied in chemical instruments and methods, transportation and packaging, mixers, etc., can solve problems such as waste of resources, inconvenient use of equipment, subsequent cleaning, and adhesion of resources, and achieve the effect of improving mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

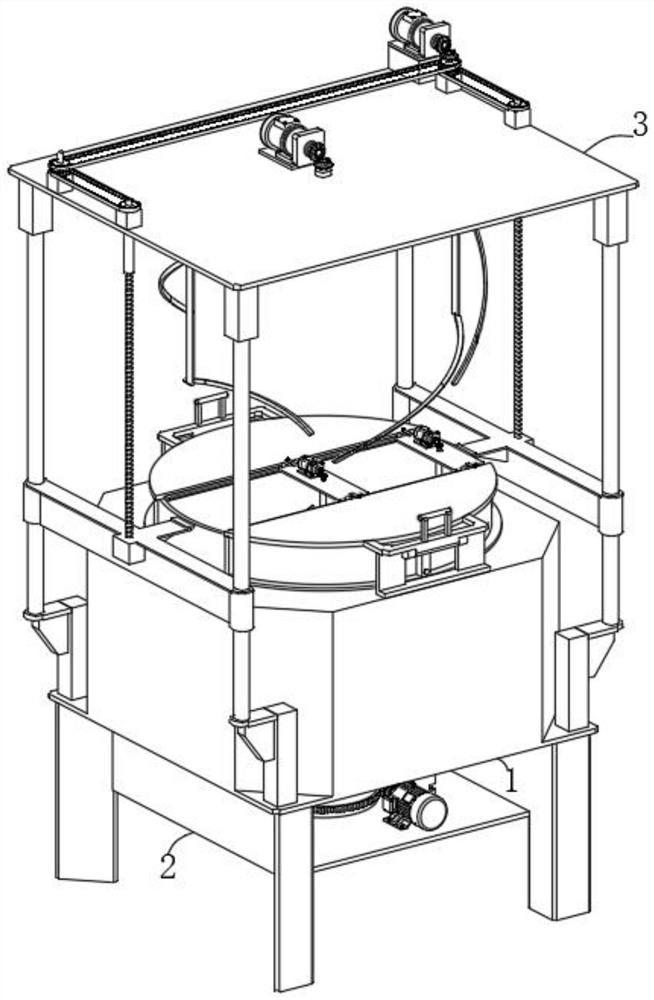

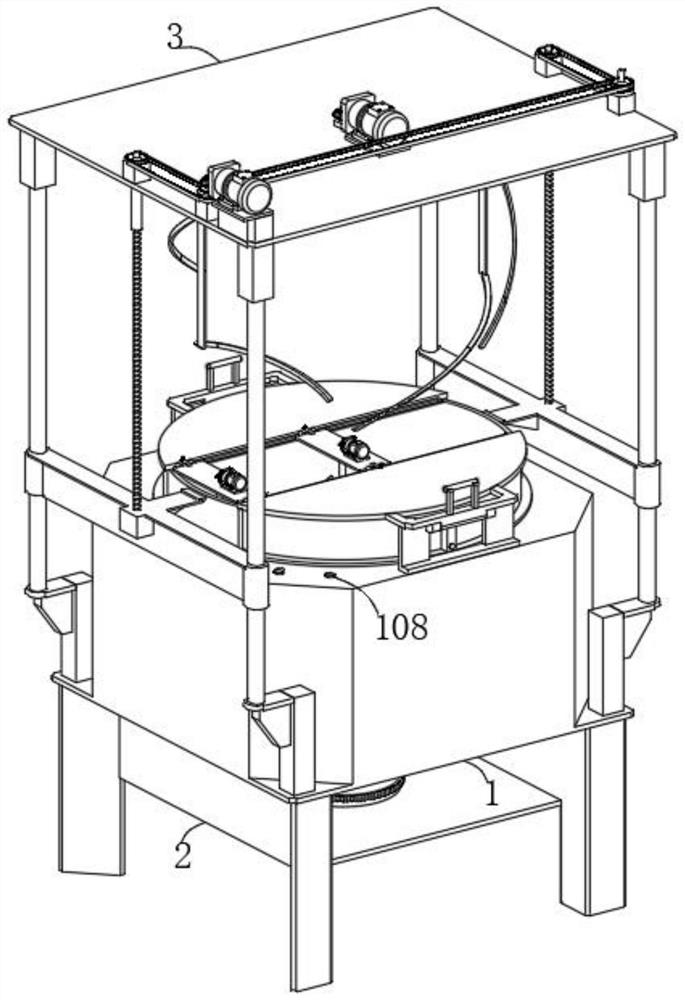

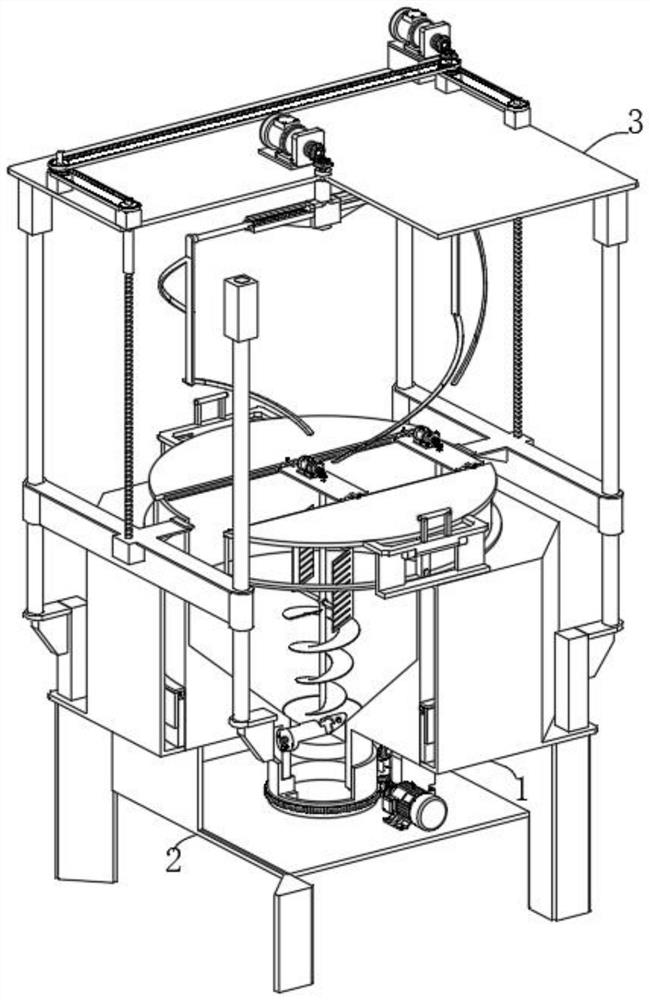

[0033] refer to Figure 1-Figure 7 : a water-based anti-corrosion steel structure paint preparation device, comprising: a support mechanism 2, a mixing mechanism 1 and an adjustment mechanism 3, the support mechanism 2 includes a base 201 and a driving part, the establishment of the base 201 provides the installation basis for other functional parts of the equipment, and at the same time The device can be stably placed at the designated place. The top of the base 201 is rotatably connected to the limit ring 202. The establishment of the limit ring 202 can effectively drive the mixing frame 103 to rotate. The outer surface of the limit ring 202 is sleeved with a gear ring 203. The establishment of the interlocking gear enables the interlocking shaft to effectively drive the limit ring 202 to rotate. The mixing mechanism 1 includes a liquid storage frame 101, a mixing part and a discharge part. The establishment of the liquid storage frame 101 cooperates with the mixing frame 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com