Rotary positive-pressure feeding bin for chlorothalonil production system and using method of rotary positive-pressure feeding bin

A feeding bin and rotary technology, applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve problems such as the use of production systems, feeding bin storage, and discomfort with chlorothalonil, etc., to improve production Efficiency, reduced use height, and reduced feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

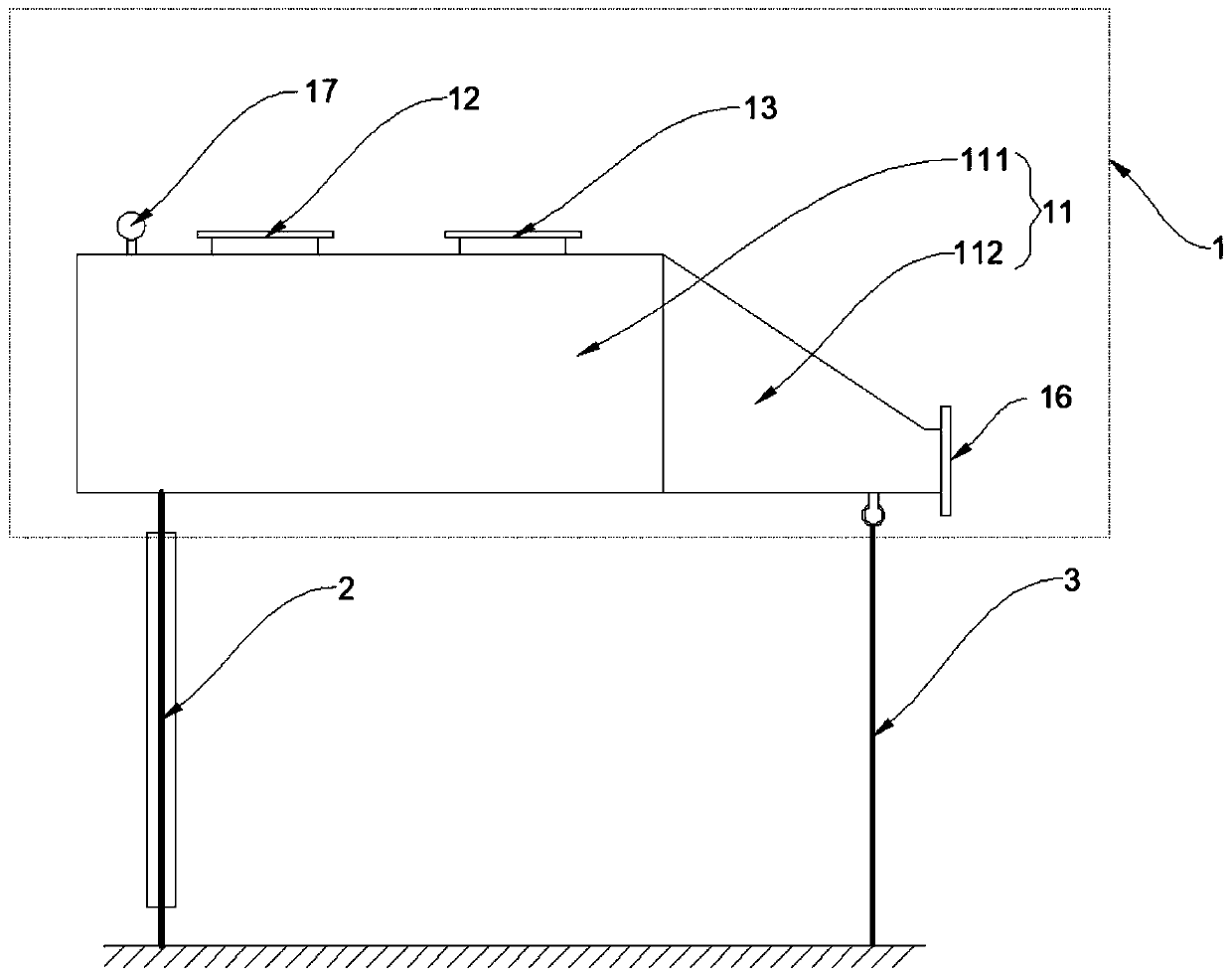

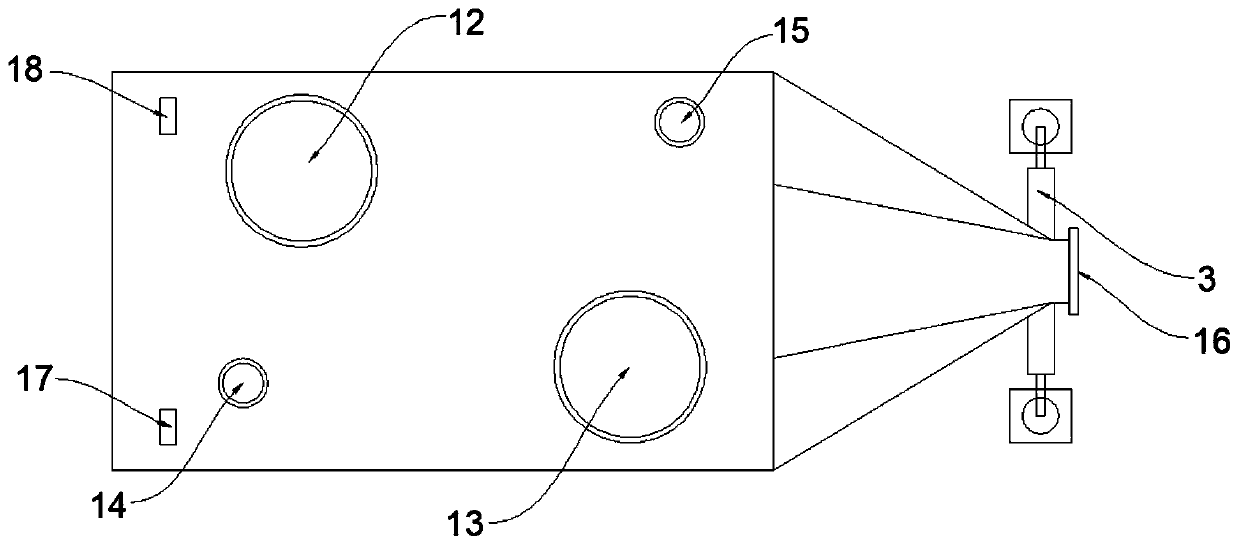

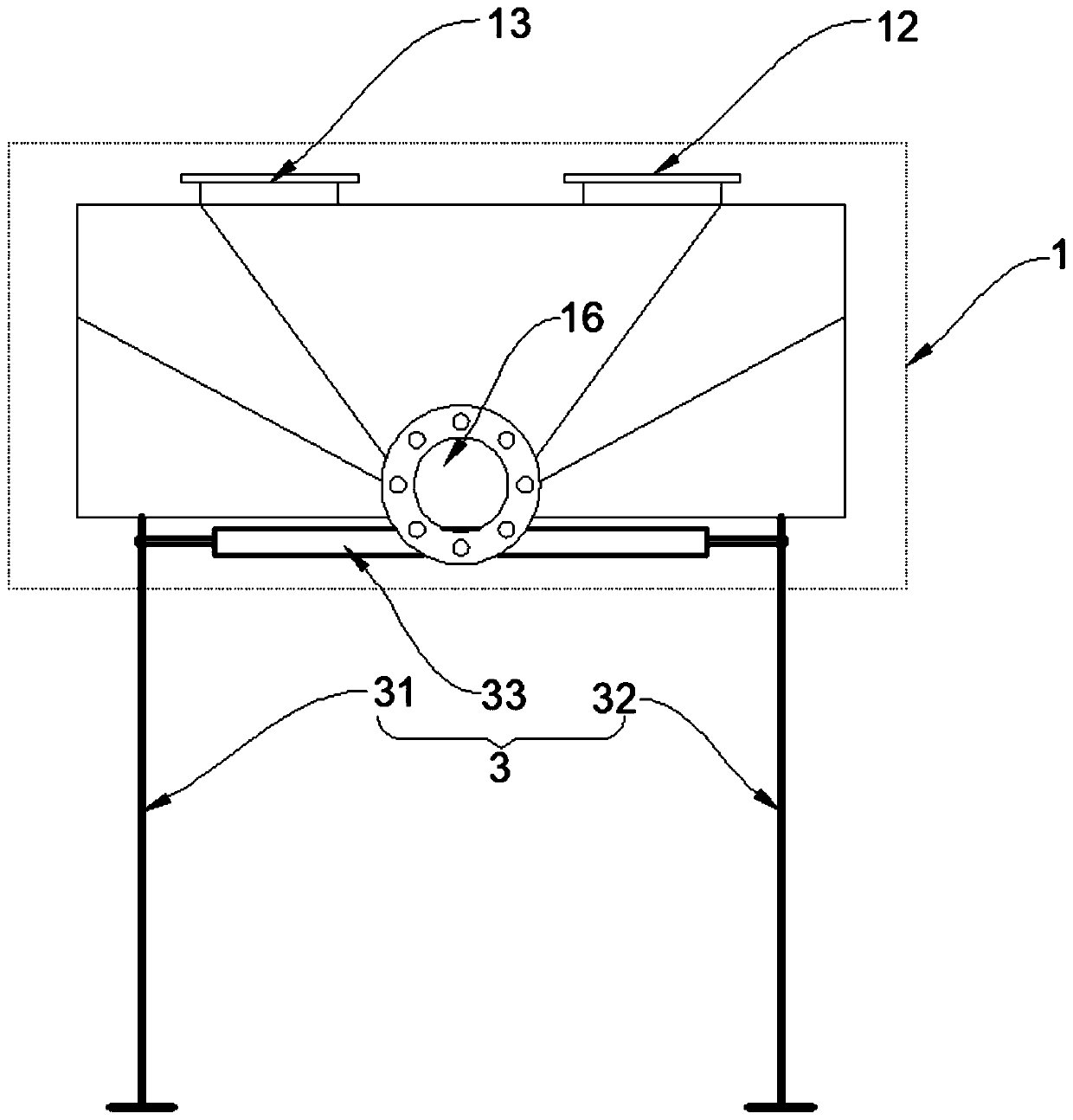

[0076] This embodiment provides a chlorothalonil production system, which includes a feed unit and a reaction unit connected in sequence.

[0077] The feeding unit includes the rotary positive pressure feeding bin provided in the specific embodiment. Exemplarily, this embodiment also provides a rotary positive pressure feeding bin suitable for the chlorothalonil production system of the present invention. Processing size, specifically, the storage section shell of the rotary positive pressure feeding bin is a cuboid structure, and the length, width and height of the storage section shell are 1600mm, 1600mm, and 500mm in turn; the row of the rotary positive pressure feeding bin The shell of the feeding section is a polyhedral cone structure, the bottom of the polyhedron cone has a width of 1600 mm, a length of 500 mm, and a height of 500 mm. The total volume of the shell of the rotary positive pressure feeding bin is about 1.5m 3 , the wall thickness is 10mm, and the material ...

Embodiment 2

[0081] In this embodiment, the production system provided in Example 1 is used to produce chlorothalonil products, and the production process specifically includes the following steps:

[0082](1) The activated carbon catalyst is fed through a rotary positive pressure feeding bin and transported to the fluidized bed reactor at a volume flow rate of 1.5-2t / h;

[0083] (2) The dinitrile of 0.5t / h and the chlorine reaction raw material of 1t / h enter the fluidized bed reactor and react with the catalyst to generate crude product chlorothalonil;

[0084] (3) The crude chlorothalonil obtained in step (2) is refined through a refining and purification unit to obtain a chlorothalonil product.

[0085] Wherein, the described feeding process of step (1) comprises the steps:

[0086] (a) Add the catalyst from the feed port of the feed bin, and close the feed port, exhaust port and discharge port of the feed bin;

[0087] (b) Open the air inlet of feeding bin, pass into nitrogen in the ...

Embodiment 3

[0091] In this embodiment, the production system provided in Example 1 is used to produce chlorothalonil products, and the production process specifically includes the following steps:

[0092] (1) The activated carbon catalyst is fed through a rotary positive pressure feeding bin and transported to the fluidized bed reactor at a volume flow rate of 2-2.5t / h;

[0093] (2) The dinitrile of 0.5t / h and the chlorine reaction raw material of 1t / h enter the fluidized bed reactor and react with the catalyst to generate crude product chlorothalonil;

[0094] (3) The crude chlorothalonil obtained in step (2) is refined through a refining and purification unit to obtain a chlorothalonil product.

[0095] Wherein, the described feeding process of step (1) comprises the steps:

[0096] (a) Add activated carbon catalyst from the feeding port of the feeding bin, and close the feeding port, exhaust port and discharge port of the feeding bin;

[0097] (b) open the air inlet of feeding bin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com