Pneumatic intelligent folding center upper pressing die hinge die and using method

An intelligent, hinged technology, applied in the direction of climate sustainability, forming tools, final product manufacturing, etc., can solve the problems of reducing the service life of the mold, reducing the lifting speed, and wear of the knife edge of the mold, achieving enhanced bending stability, The effect of improving production efficiency and shortening bending time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

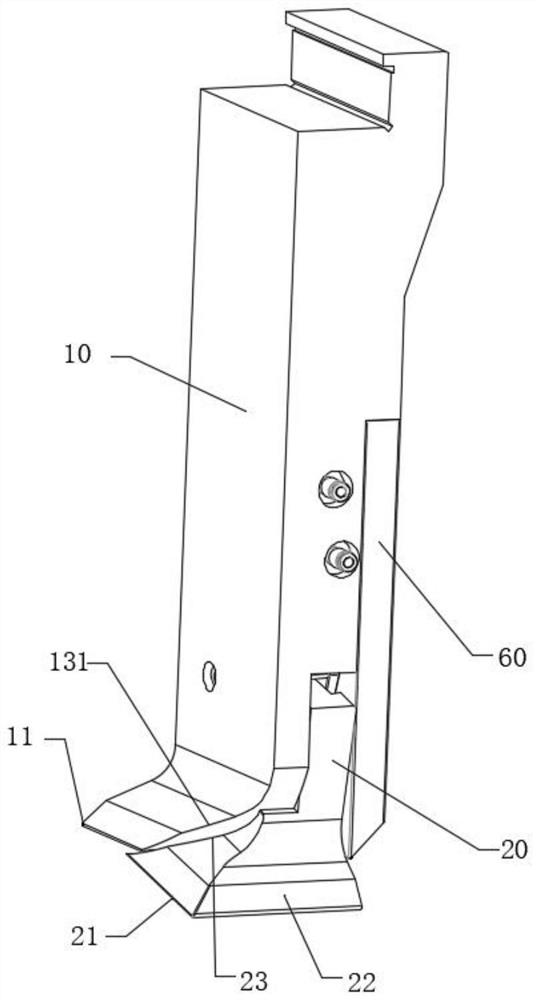

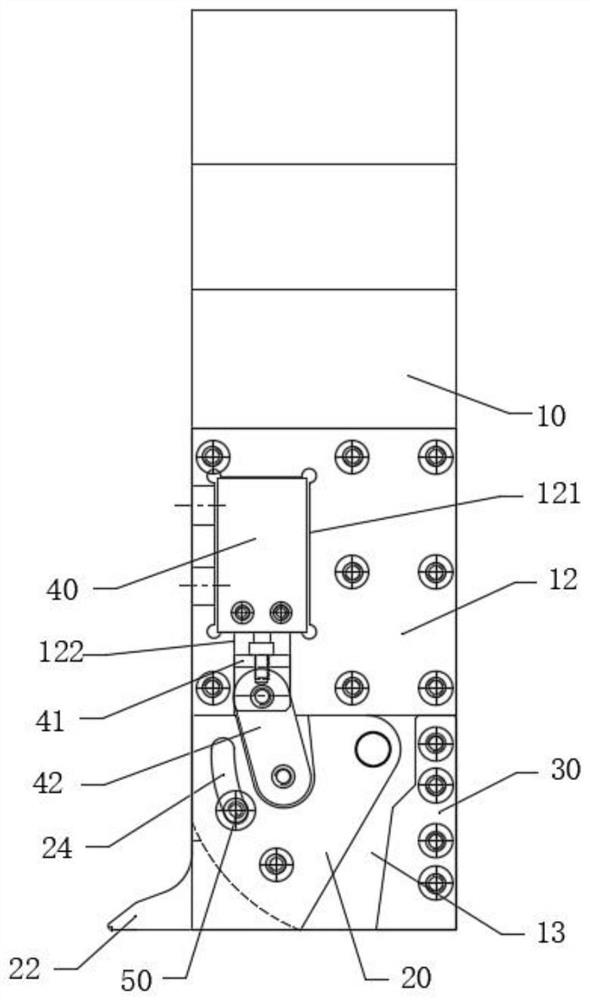

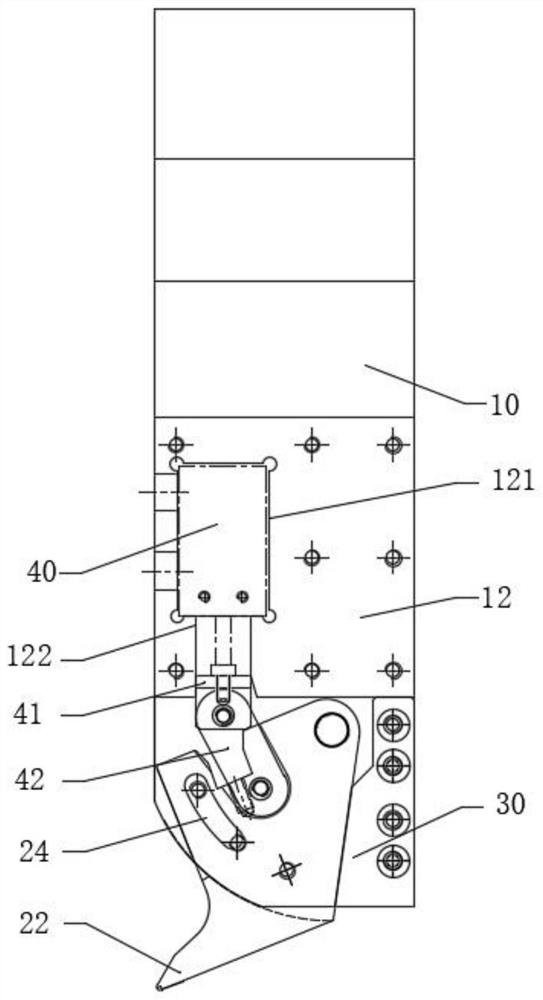

[0029] like Figure 1 to Figure 8 As shown, a pneumatic intelligent hemming center upper pressing die hinge die, including a die body 10, the die body 10 is provided with an upper step surface 12 and a lower step surface 13, and the upper step surface 12 is provided with a drive mechanism for installing The mounting groove 121 and the guide groove 122 are provided, the bottom of the mold body 10 is provided with a main body knife edge 11, and a driving mechanism (on the upper step surface) is installed on the mold body 10. The driving mechanism is the power source and rotates relative to the mold body 10. The movable ear knife 20 (on the lower step surface), and the positioning block 30 (on the lower step surface) suitable for defining the position of the movable ear knife 20 .

[0030] The driving mechanism includes an air cylinder 40 installed inside the installation groove 121. The output end of the air cylinder 40 is connected with a sliding block 41 that is slidingly matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com