Steel bar positioning and binding assembly

A component and steel bar technology, applied in the field of steel bar positioning and binding components, can solve the problems of high labor cost and low efficiency, and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

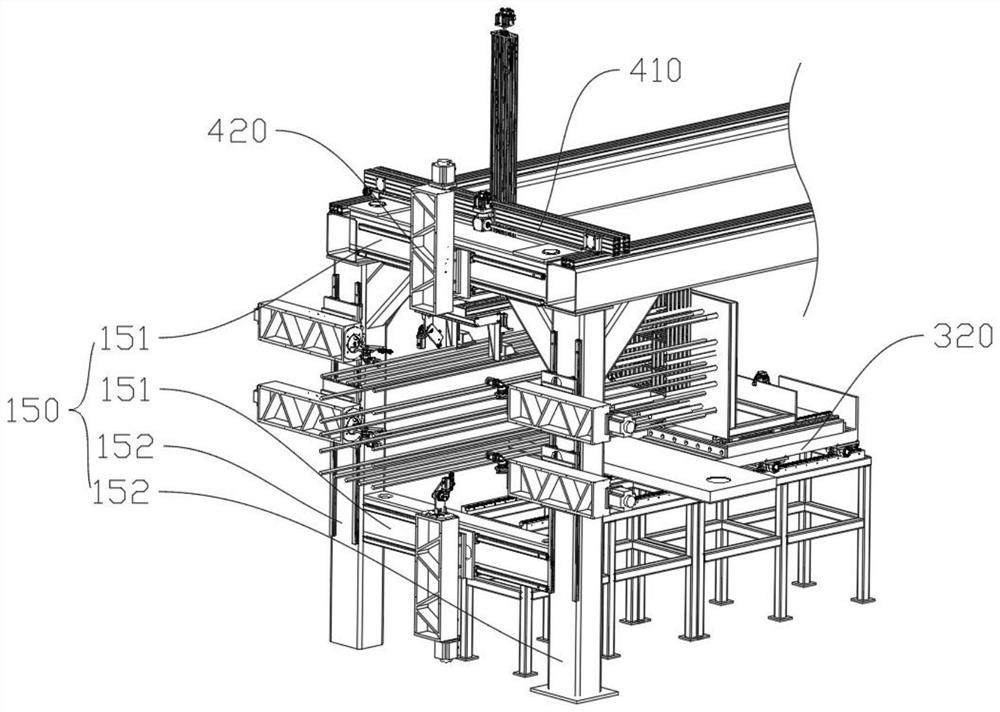

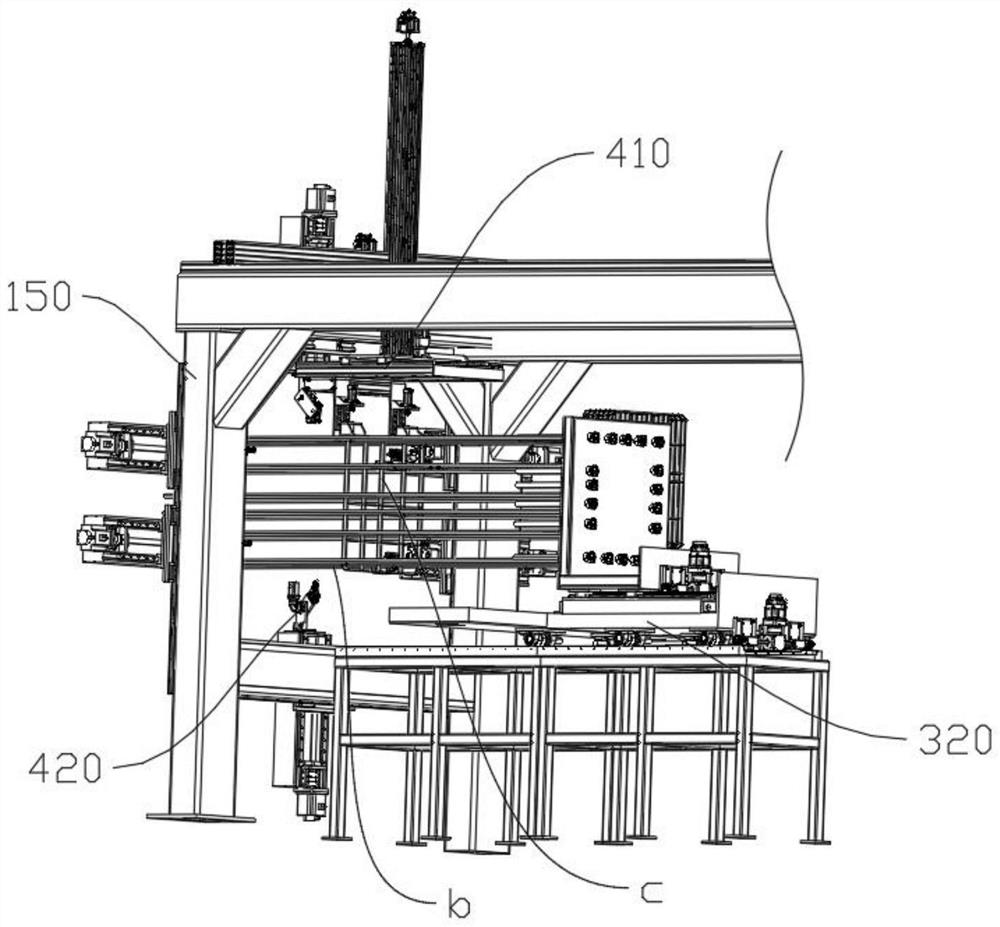

[0035] like Figure 1-7As shown in the figure, the reinforcing bar positioning and binding assembly of Embodiment 1 includes a frame, a reinforcing bar cage binding unit connected to the frame, and a stirrup material box 910 for stacking stirrup groups, and several longitudinal bars pass through the frame. In the stirrup magazine 910; the reinforcement cage binding unit includes a stirrup moving component 410 for moving the stirrups on the stirrup magazine 910 to the binding position one by one, and a stirrup moving assembly 410 for moving the stirrups on the binding position one by one. The binding robot 420 bound with the longitudinal bars, the stirrup material box 910 , the stirrup moving assembly 410 and the binding robot 420 are arranged in sequence along the conveying direction of the longitudinal bars.

[0036] The frame includes a fixed binding truss 150 , and the binding robot 420 is connected to the binding truss 150 .

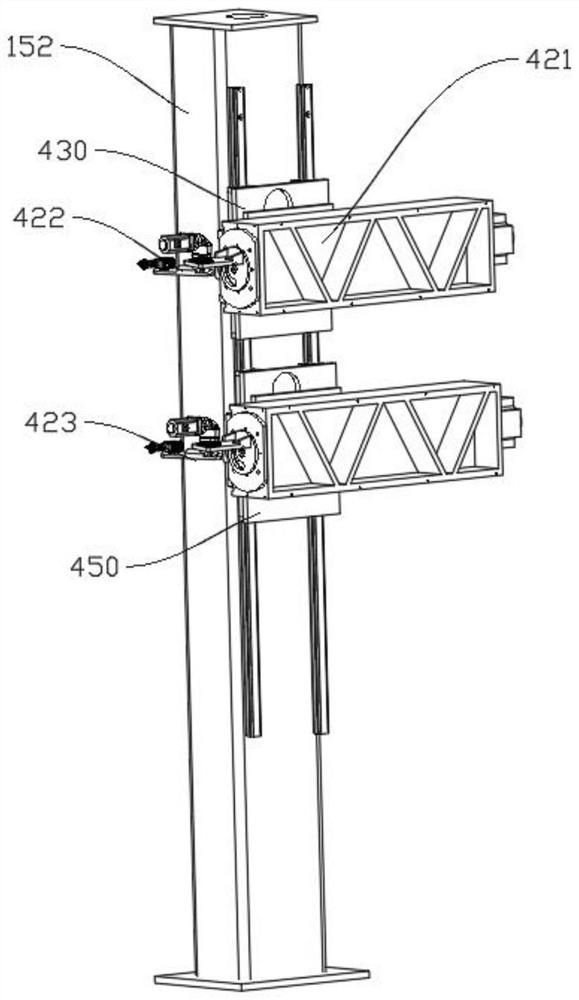

[0037] The binding robot 420 includes a bindi...

Embodiment 2

[0054] like Figure 8-13 As shown, Embodiment 2 is based on Embodiment 1, except that: the frame includes a stirrup truss 120; 820, the claw seat 810 is slidably matched with the stirrup truss 120, and between the claw seat 810 and the stirrup truss 120 is provided for driving the claw seat 810 between the stirrup material box 910 and the binding position. The claw seat drive assembly that reciprocates between them.

[0055] The stirrup grasping member 820 includes a lower transverse claw 821 fixedly connected with the claw seat 810 , an upper pressing claw 822 slidably connected with the claw seat 810 , and driving the upper pressing claw 822 and the lower transverse claw. 821 is attached to or separated from the pressing claw driving assembly, and the sliding direction of the upper pressing claw 822 is set vertically.

[0056] The claw driving assembly includes a claw cylinder 823, the cylinder body of the claw cylinder 823 is fixedly connected with the claw seat 810, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com