Multi-truss prefabricated folding lagging jack and erection method thereof

An arch and pedestal technology, which is applied to the field of multiple prefabricated folding arches, can solve the problems of inconvenient installation process and large workload of installation personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

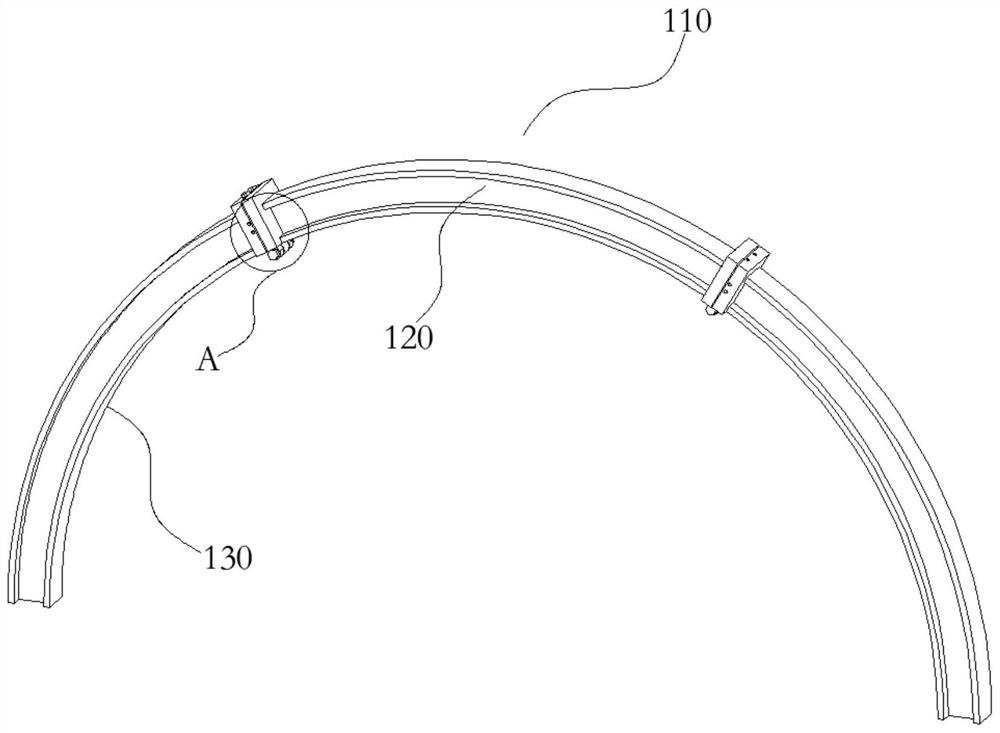

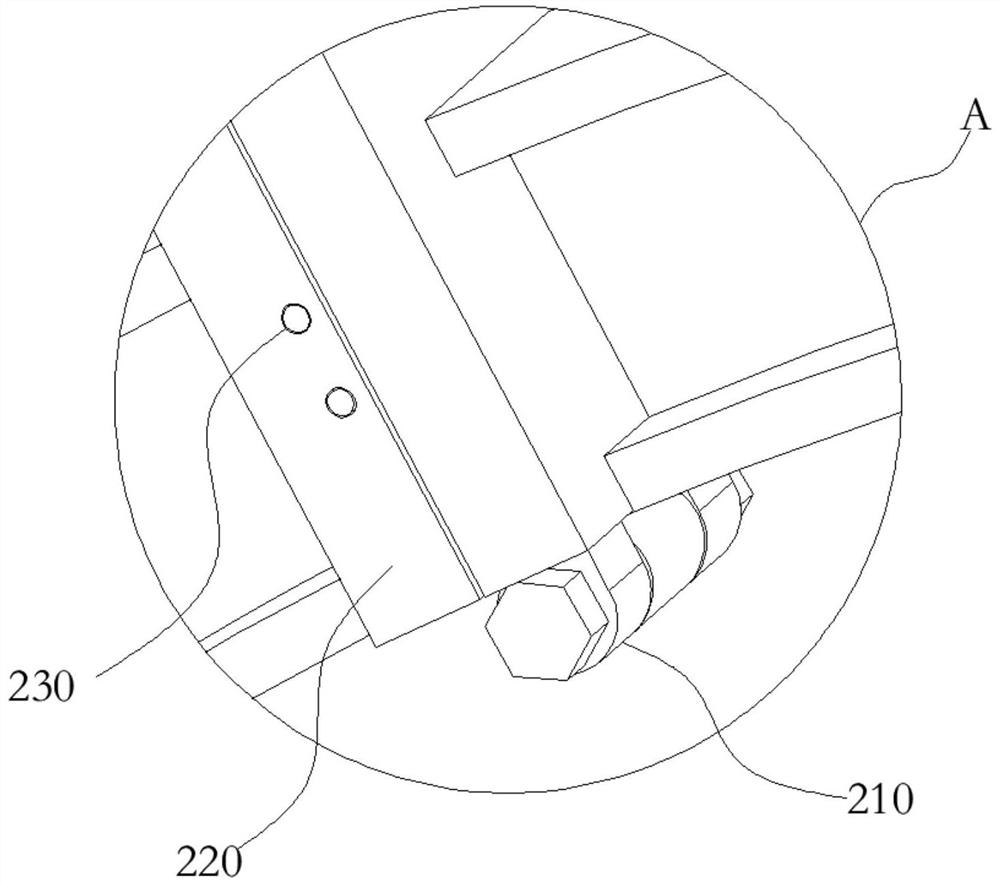

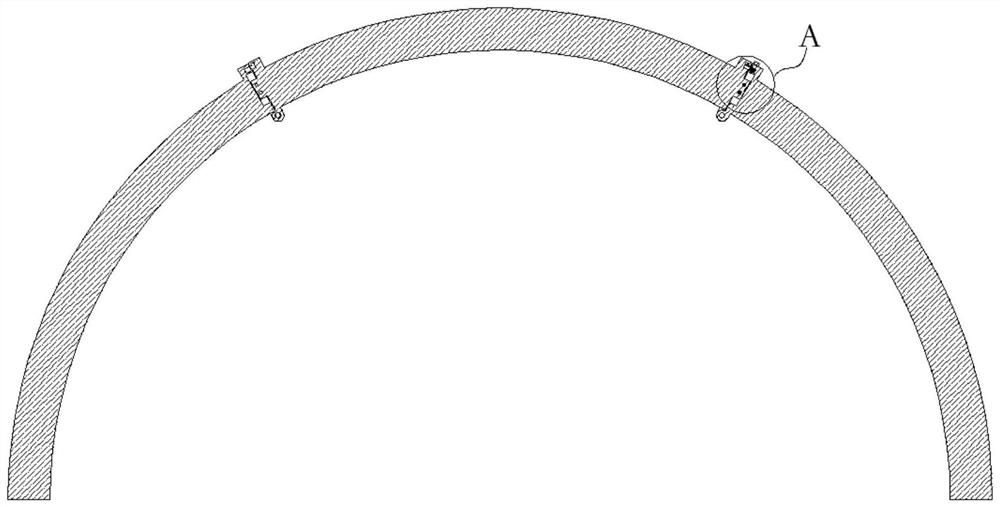

[0027] like figure 1 , 2 , 5, the present embodiment provides a multiple prefabricated folding arch, which includes an arch body 110, and the arch body 110 includes a top arch 120 and a base arch 130 disposed at both ends of the top arch 120, Both the top arch 120 and the base arch 130 include arc-shaped strip plates 510 . The inner and outer ends of the strip plates 510 are provided with annular sheets 520 arranged perpendicular to the strip plates 510 . Both ends of the top arch 120 and the end of the base arch 130 close to the top arch 120 are provided with hinges 210 , and bolts between the top arch 120 and the hinges 210 on the base arch 130 connect. The top arch 120 is hinged with the base arches 130 at both ends, and the two ends of the top arch 120 and the base arches 130 at both ends are provided with a connection for connecting the top arch 120 and the base arch 130 . connector.

[0028] When the multiple prefabricated folding arches in this embodiment are stored...

Embodiment 2

[0037] The present embodiment provides a method for erecting the multiple prefabricated folding arches in the embodiment, which includes the following steps:

[0038] Step 1. Make multiple prefabricated folding arches and assemble them outside the tunnel;

[0039] Step 2: Fix the top arch frame 120 of the multi-pronged prefabricated folding arch frame assembled in step 1 on the crawler-type three-arm three-basket arch frame installation trolley. The crawler-type three-arm three-basket arch frame installation platform in this embodiment is The truck adopts the LGP340A arch-spray integrated trolley produced by Lanhai Zhizhuang; after that, the multiple prefabricated folding arches are transported to the installation site in the tunnel;

[0040] Step 3, start the crawler-type three-arm three-basket arch installation trolley to unfold the multiple prefabricated folding arches until the L-shaped plate 470 on the base arch 130 is inserted into the L-shaped groove 460;

[0041] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com