Mobile platform

A mobile platform, one-to-one technology, applied in the field of mobile platforms, can solve the problems of difficult cascading of mobile platforms, limited delivery of goods by a single mobile platform, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

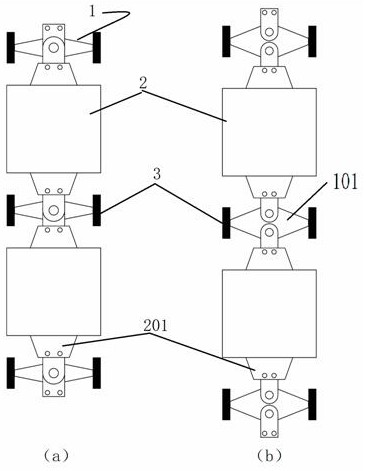

[0032] The invention discloses a mobile platform, which comprises a chassis 2 and a drive bridge 1, wherein the number of the two chassis is N, and the number of one drive bridge is N+1, where N is a positive integer greater than or equal to 1. The drive axle 1 includes a drive axle support 101 and wheels rotatably connected to both ends of the drive axle support 101, chassis hinge connectors 201 are arranged on both sides of the chassis 2, N chassis 2 and N+1 drive axles 1 are arranged at intervals in sequence, and the drive axle 1 can rotate relative to the chassis 2, and the drive axle bracket 101 is hinged to the chassis hinge connection part 201 through a coaxial hinge. The angle of the wheel 3 relative to the drive axle support 101 is constant, and the wheel 3 is provided with a wheel driving mechanism to drive it to rotate.

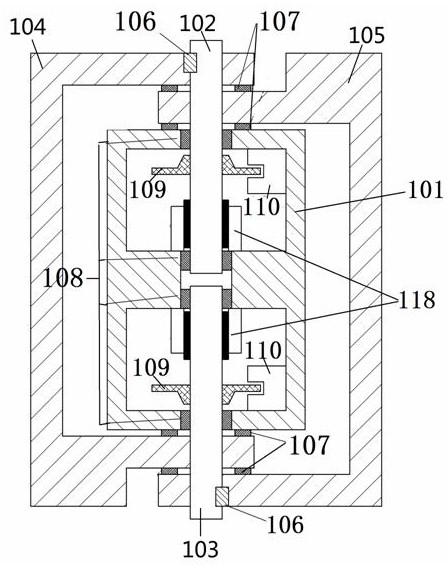

[0033]In this embodiment, N=1, so the mobile platform is a four-wheel trolley structure. In this embodiment, the drive axle support 101 and the ch...

Embodiment approach 2

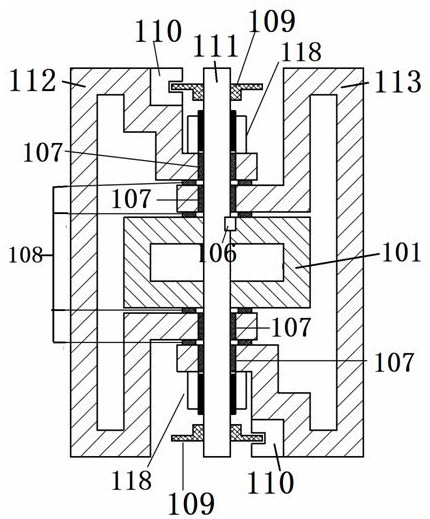

[0044] The difference between this embodiment and Embodiment 1 is: see the attached image 3 , the coaxial hinge includes a hinge shaft three 111 and a hinge connection part three 112 and a hinge connection part four 113 arranged symmetrically in the center, the hinge shaft three 111 runs through the drive axle support 101, and is fixed on the drive axle support 101 by a fixing key 106; the hinge Connecting part 3 112 and hinge connecting part 4 113 are hollow inside, and the two are interspersed and arranged on the upper side and the lower side of the drive axle bracket 101. 3 111, see attached image 3 , Bearings 108 are provided with 4 pieces, respectively arranged on the upper and lower side walls of hinge connector three 112 and hinge connector four 113 and are rotationally connected with hinge shaft three 111 . The other ends of the hinge connector three 112 and the hinge connector four 113 are fixedly connected to the chassis hinge connector 201, and the hinge connecto...

Embodiment approach 3

[0050] This embodiment differs from Embodiment 1 and Embodiment 2 in that: the transaxle support 101 and the chassis hinge connector 201 are hinged through a biaxial hinge, and the biaxial hinge includes hinge axis four 114, hinge axis five 115, hinge connection Part five 116, hinge connection part six 117. The four chain shafts 114 and the five hinge shafts 115 are arranged in parallel with different axes, and they respectively run through the drive axle brackets 101 close to the chassis 2 on both sides. Five 116, the hinge connector six 117 is fixedly connected, the hinge connector five 116, the hinge connector six 117 are hollow inside, and both of them are sleeved on the upper side and the lower side of the drive axle bracket 101; the hinge connector five 116, the hinge connector Six 117 are rotatably connected to the drive axle support 101 through thrust bearings 107 respectively. In this embodiment, four thrust bearings 107 are set, see the attached Figure 4 , 2 thrust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com