Method for determining height of strip mine dragline dumping operation platform

A determination method and dragline technology, applied in data processing applications, prediction, geometric CAD, etc., can solve the problems of low operation efficiency and inability to determine the height of the dragline stacking operation platform, etc., and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described in detail below with reference to specific embodiments and accompanying drawings. It is only intended to describe the specific embodiments of the present invention in detail, and does not impose any limitation on the present invention, and the protection scope of the present invention is subject to the claims.

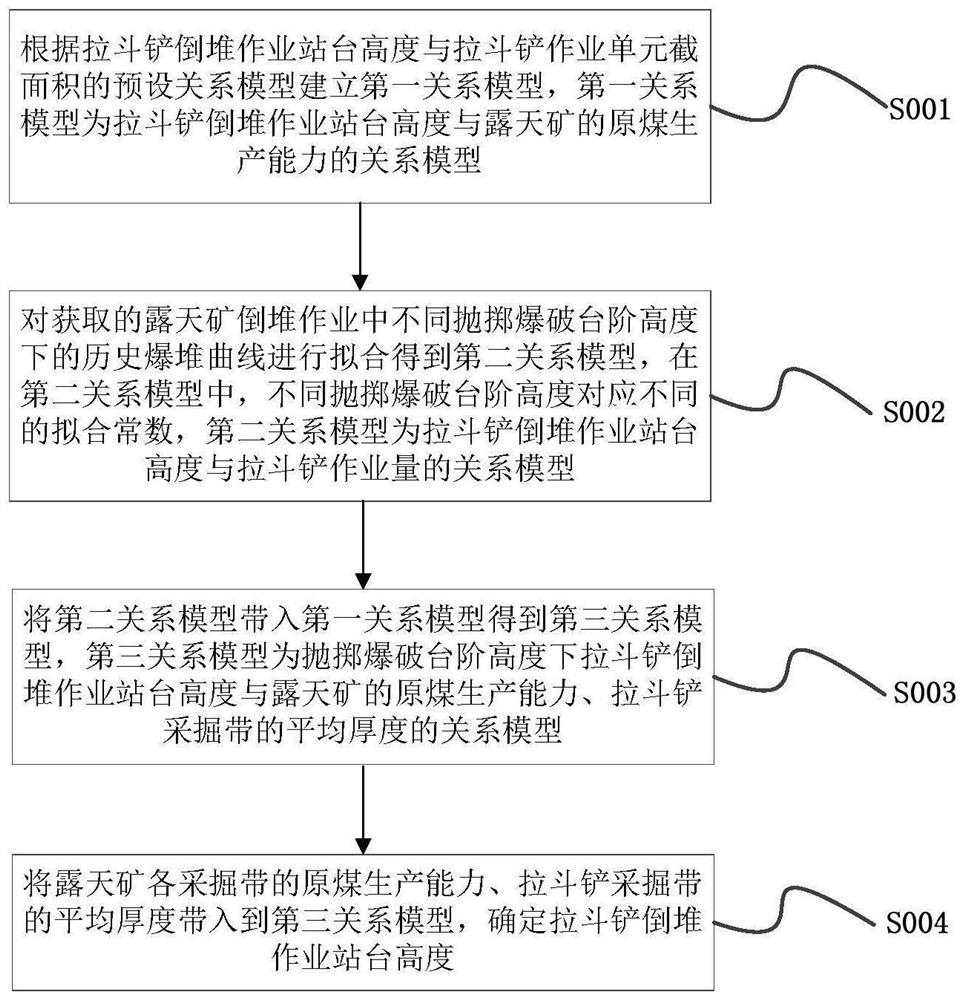

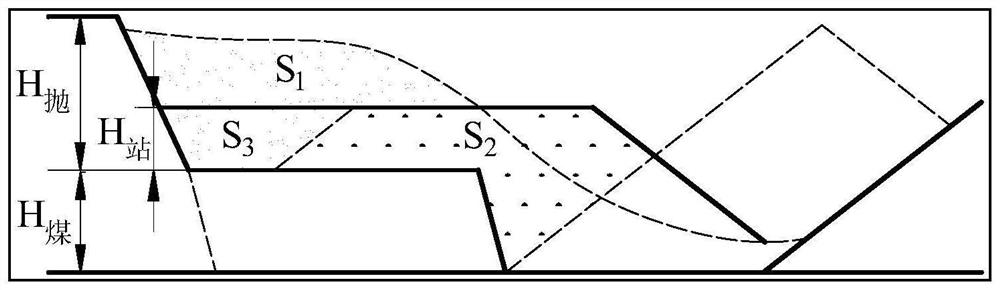

[0076] refer to figure 1 , The present invention proposes a method for determining the height of the operating platform of an open pit mine, including:

[0077] Step S001, establishing a first relationship model according to the preset relationship model between the height of the dragline dumping operation platform and the cross-sectional area of the dragline operation unit, and the first relationship model is the height of the dragline dumping operation platform and the raw coal production of the open pit mine A relational model of capabilities;

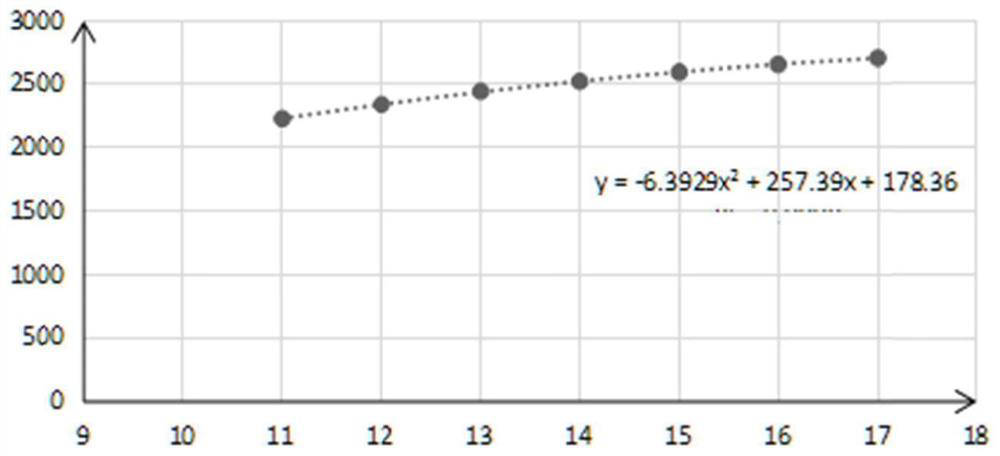

[0078] Step S002, fitting the acquired historical blasting curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com