Automatic tray distribution system for cigarette auxiliary materials

An auxiliary material and plate matching technology, which is applied in the general control system, control/regulation system, electric/hybrid power, etc., can solve the problems of small batches, increased batches, and low operating efficiency of the plate matching mode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

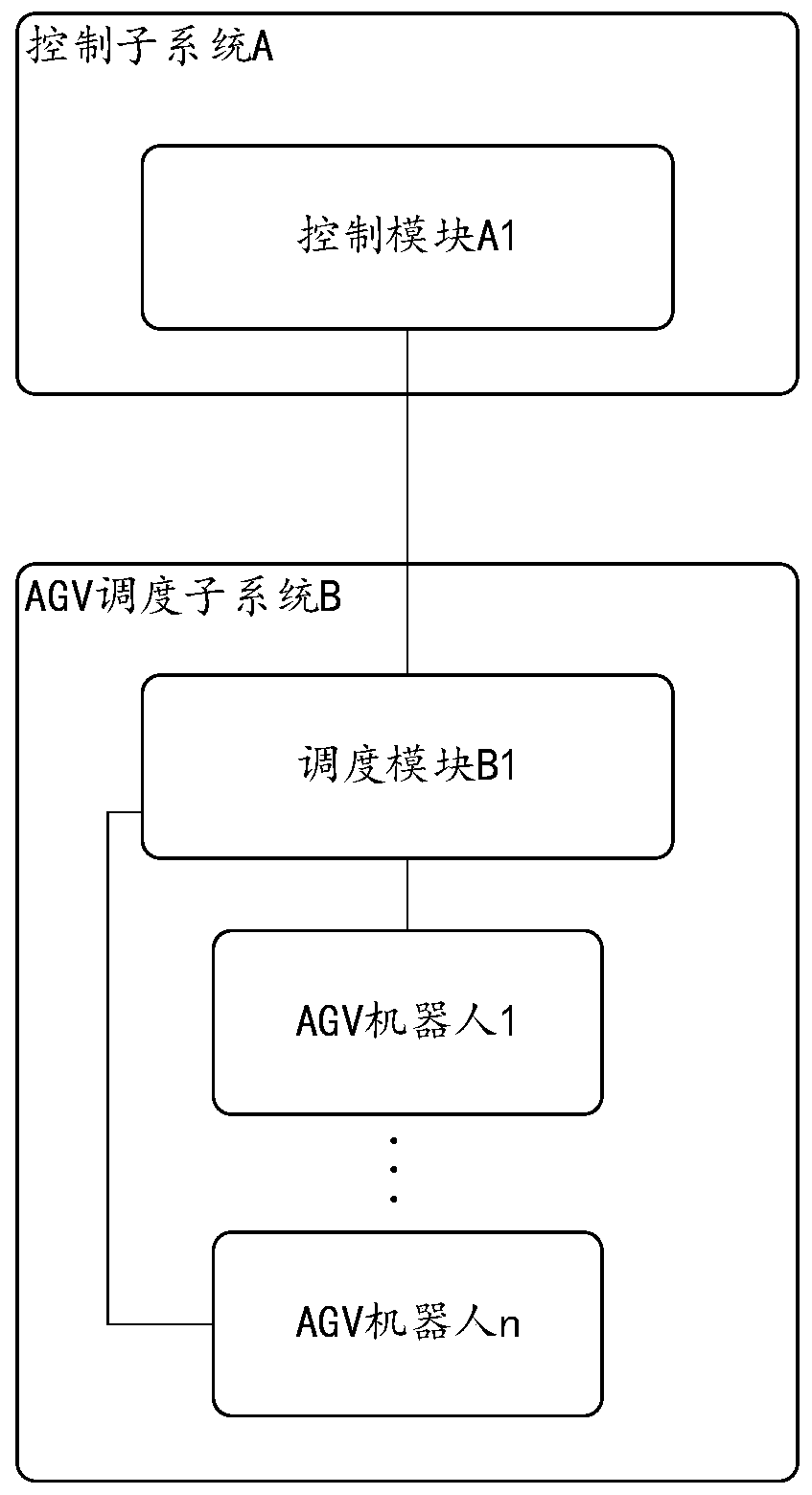

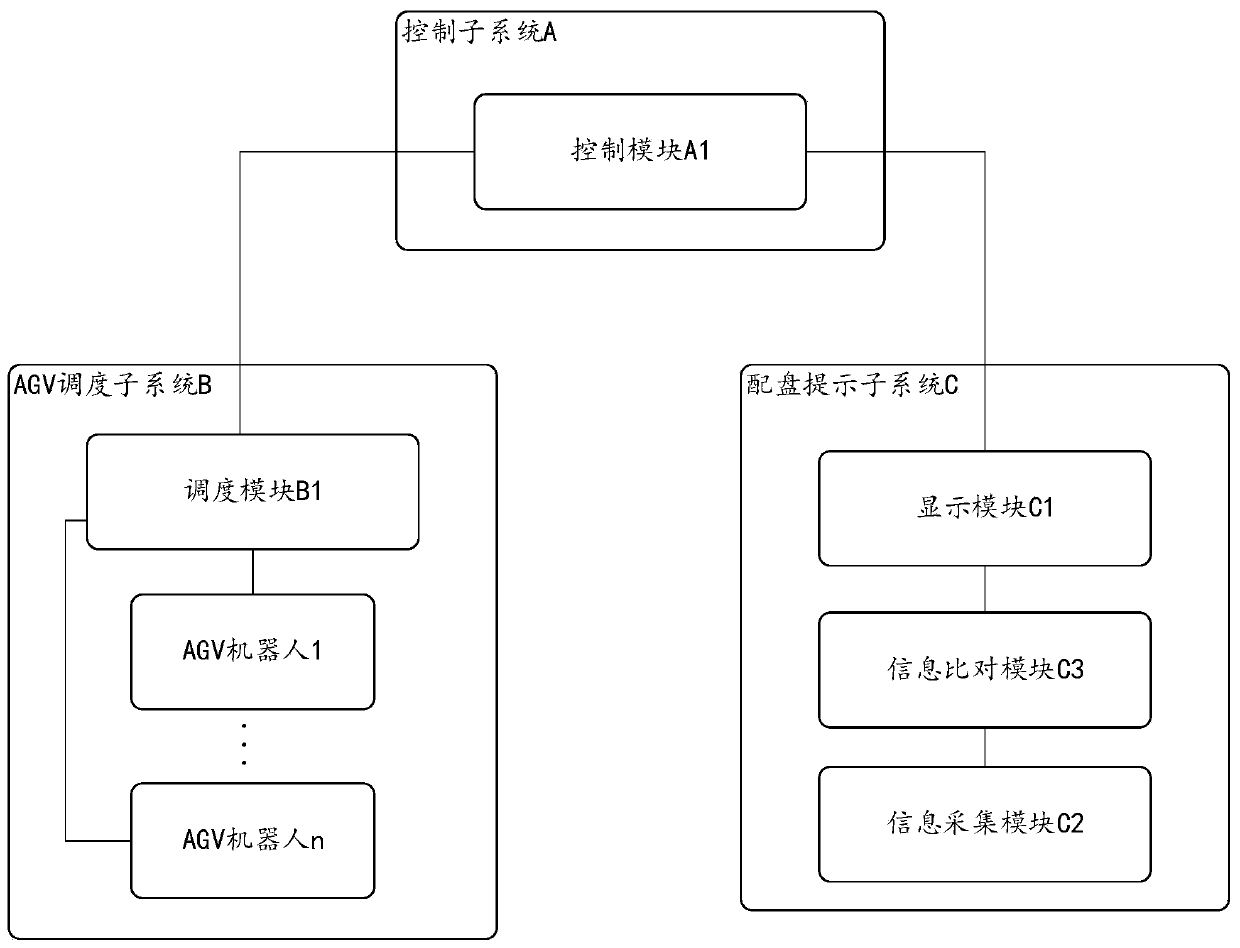

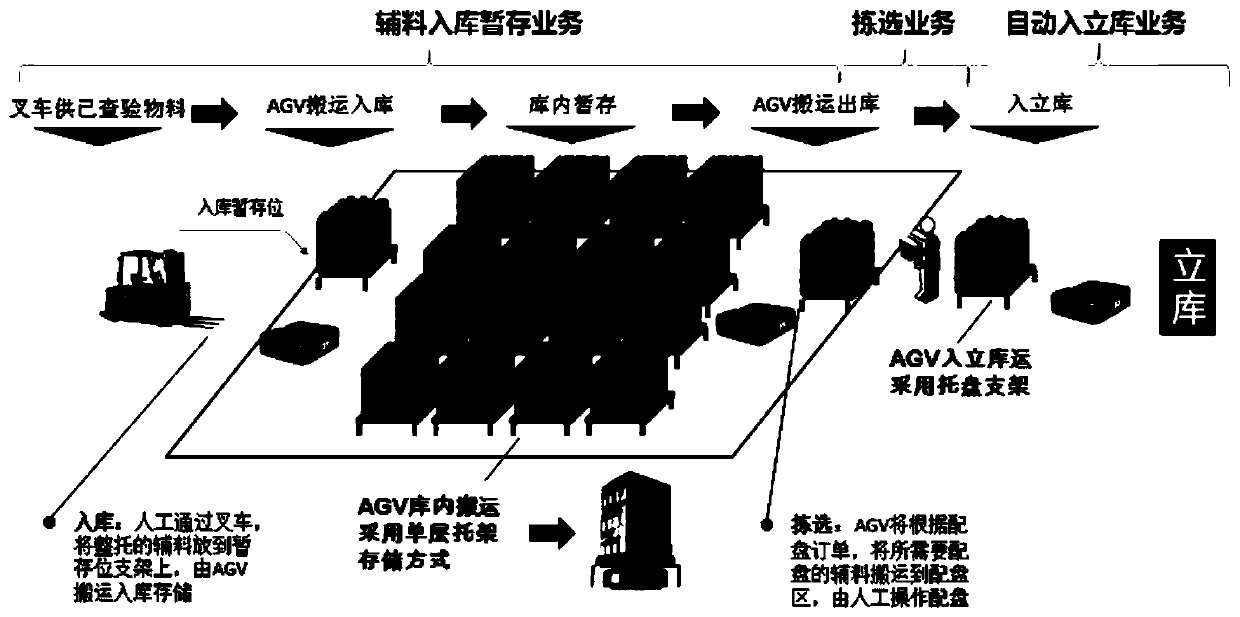

[0034] The embodiment of the present application provides an automatic distribution system for cigarette auxiliary materials, which is used to solve the problem that due to the continuous increase of cigarette product specifications, the batch size of single-brand distribution per shift is small, the number of batches increases, and the types of distribution are more and more, which greatly increases The time cost of staff searching for and transporting auxiliary materials leads to the technical problem of low operating efficiency in the existing plate matching mode.

[0035] In order to make the purpose, features and advantages of the present application more obvious and understandable, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the following The described embodiments are only some of the embodiments of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com