Artware appearance defect detection method based on unsupervised image segmentation

A technology for image segmentation and appearance defects, applied in image analysis, image data processing, instruments, etc., can solve problems such as low reusability, difficulty in supervising industrial quality inspection of learning models, waste of labor costs, etc., to achieve efficient and accurate segmentation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

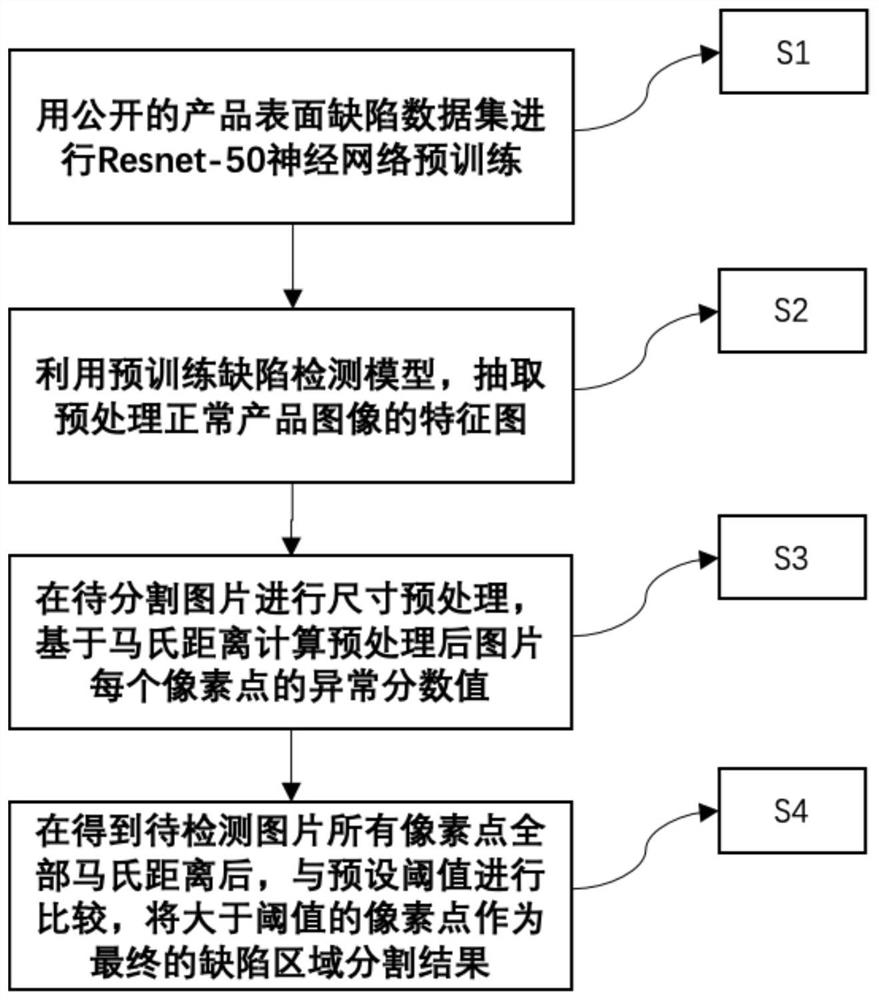

[0037] A method for detecting the appearance defects of handicrafts based on unsupervised image segmentation, such as figure 1 shown, including:

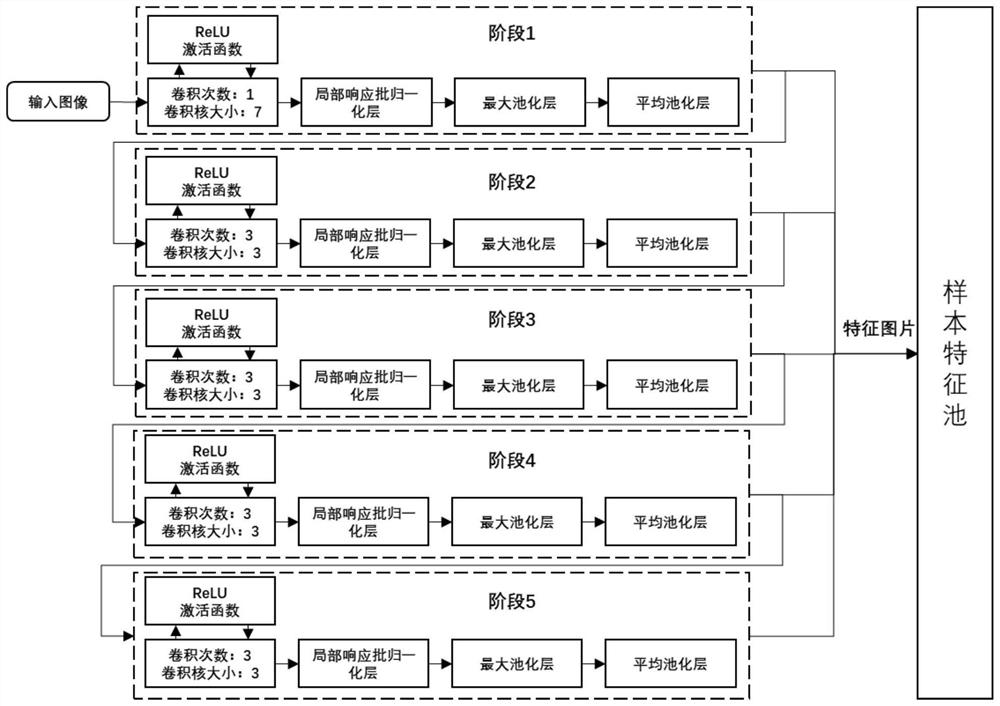

[0038] S1. Use the public cross-domain defect data set to train the deep convolutional neural network model ResNet-50 to generate a pre-trained defect detection model;

[0039] S2. Use the pre-trained defect detection model to extract and establish a feature map of normal product images, and build a sample feature library;

[0040] S3. When performing defect segmentation on the product image, use the pre-trained defect detection model to extract image features, generate a low-rank feature matrix, and calculate the abnormal score value of each pixel of the image based on the Mahalanobis distance;

[0041] S4: Select all the pixels whose abnormal score value is greater than the preset threshold as the result of the defect segmentation of the product image.

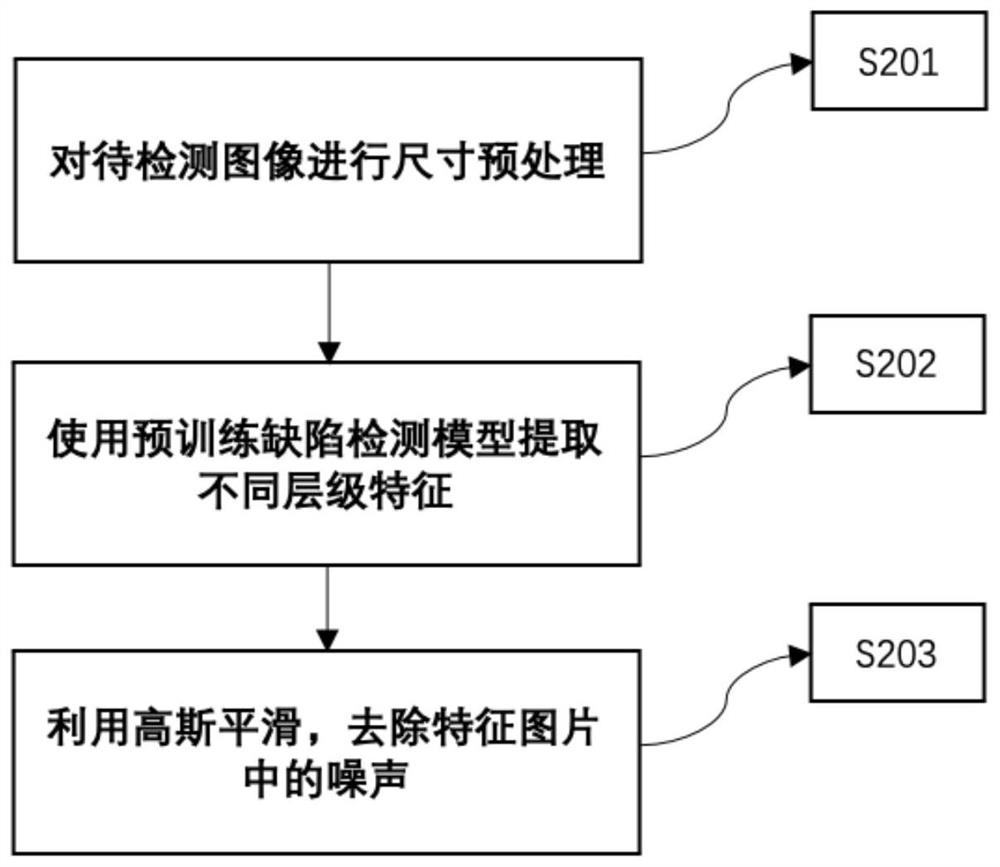

[0042] like figure 2 As shown, S2 includes:

[0043] S201. Preprocess th...

Embodiment 2

[0066] The defect detection method proposed in this application is compared with four mainstream segmentation-based defect detection methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com