Repair device for road corrugated beam guardrail

A technology for corrugated beam guardrails and highways, which is applied in the field of repair devices for highway corrugated beam guardrails, can solve the problems of lack of on-site correction equipment for corrugated beam guardrails, and achieve good orthopedic effects and little impact on structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

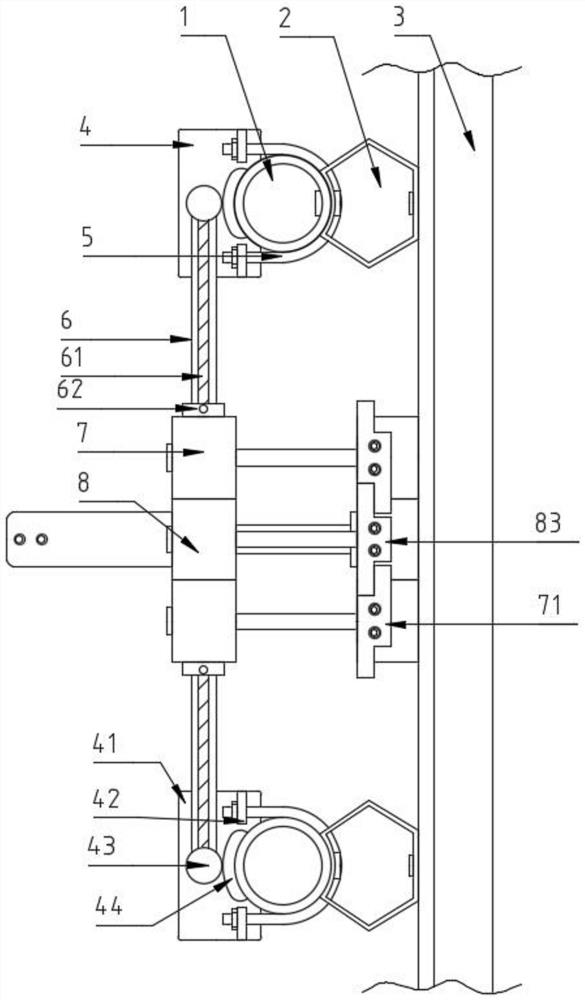

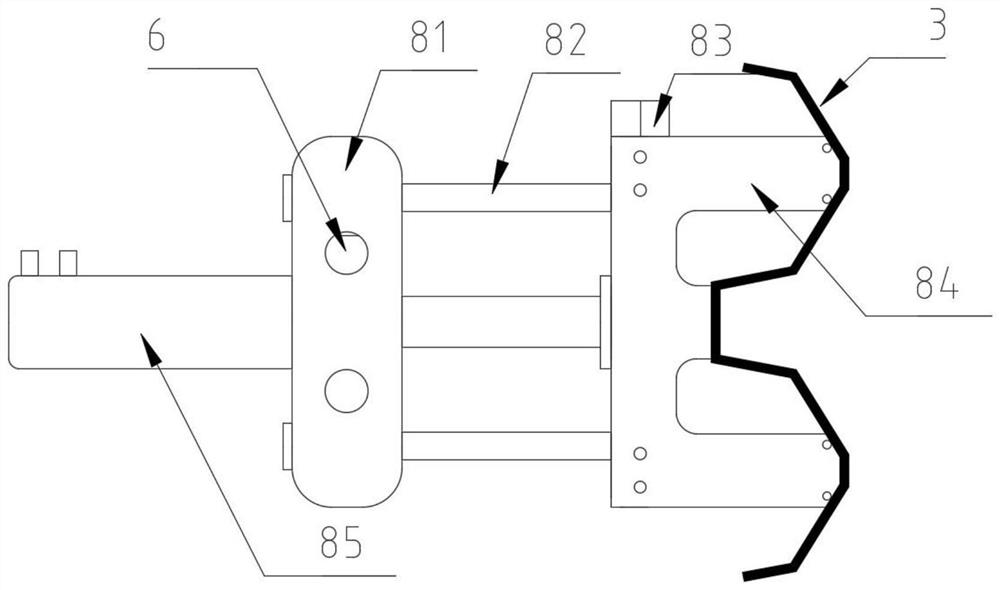

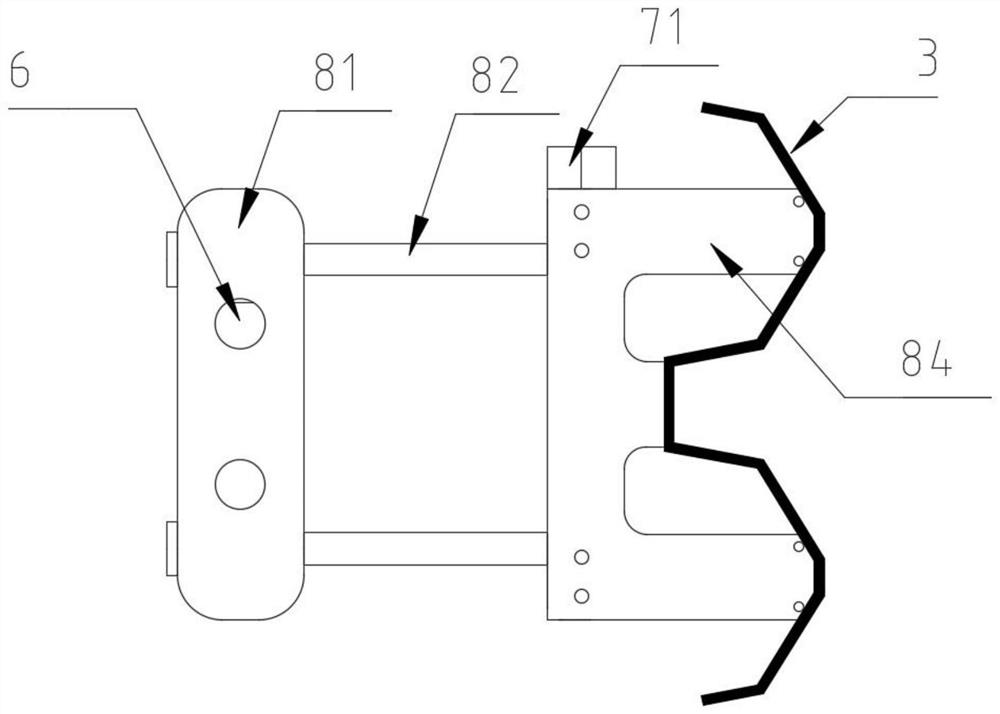

[0029] like Figure 1-6 The shown repairing device for highway corrugated beam guardrail includes connecting bases 4, two connecting bases 4 are provided, and are respectively fixed on two adjacent uprights 1 by connecting pieces 5, so as to facilitate disassembly and assembly.

[0030] And the structure is that the connecting base 4 includes a mounting seat 41, the mounting seat 41 is symmetrically provided with a connecting vertical plate 42, the connecting piece 5 is U-shaped, and both ends are provided with threads and respectively penetrate the connecting vertical plate 42 and then pass through the nut. It is fixed with the connecting base 4. In order to ensure that the fixed device is in a fixed state, an arc-shaped positioning plate 44 needs to be provided on the mounting base 41, which is set close to the vertical column 1 for limiting and positioning. The guide rail 6 is fixed on the mounting seat 41 through the mounting column 43 . It is easy to disassemble and fix,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com