Sanding treatment device and method based on combined carbon fiber sanding machine

A processing device, carbon fiber technology, applied in textiles and papermaking, fabric surface trimming, roughening, etc., can solve the problem of difficulty in collecting fines, achieve the effect of reducing operation difficulty, reducing production cost, and reducing floating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

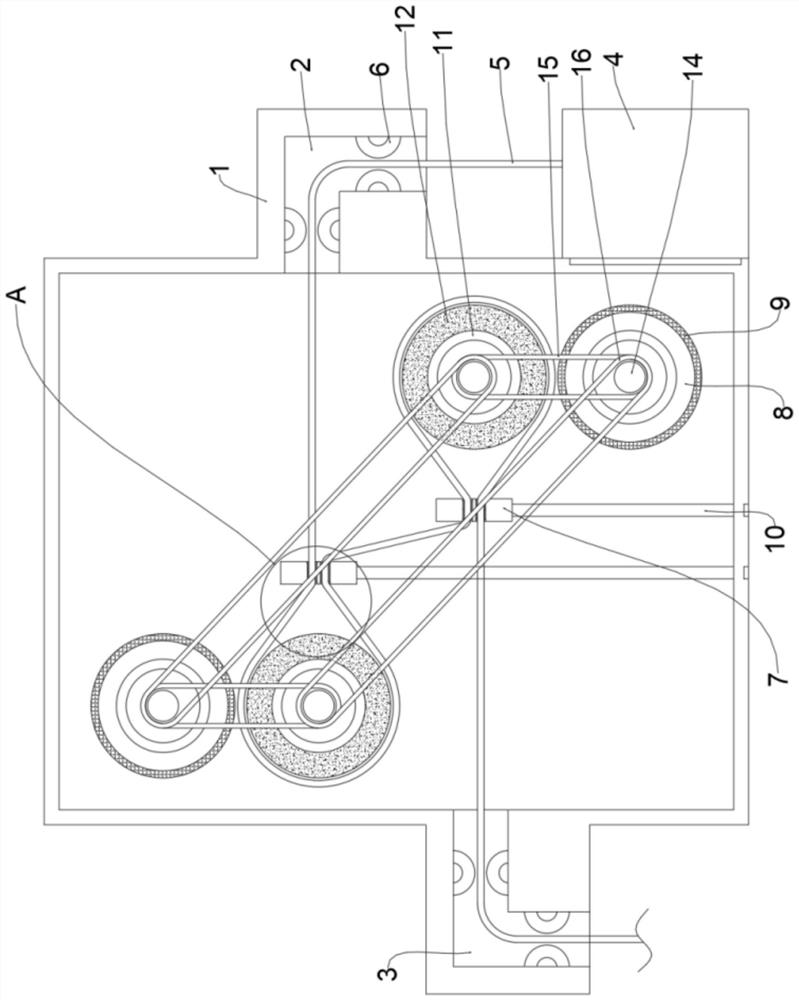

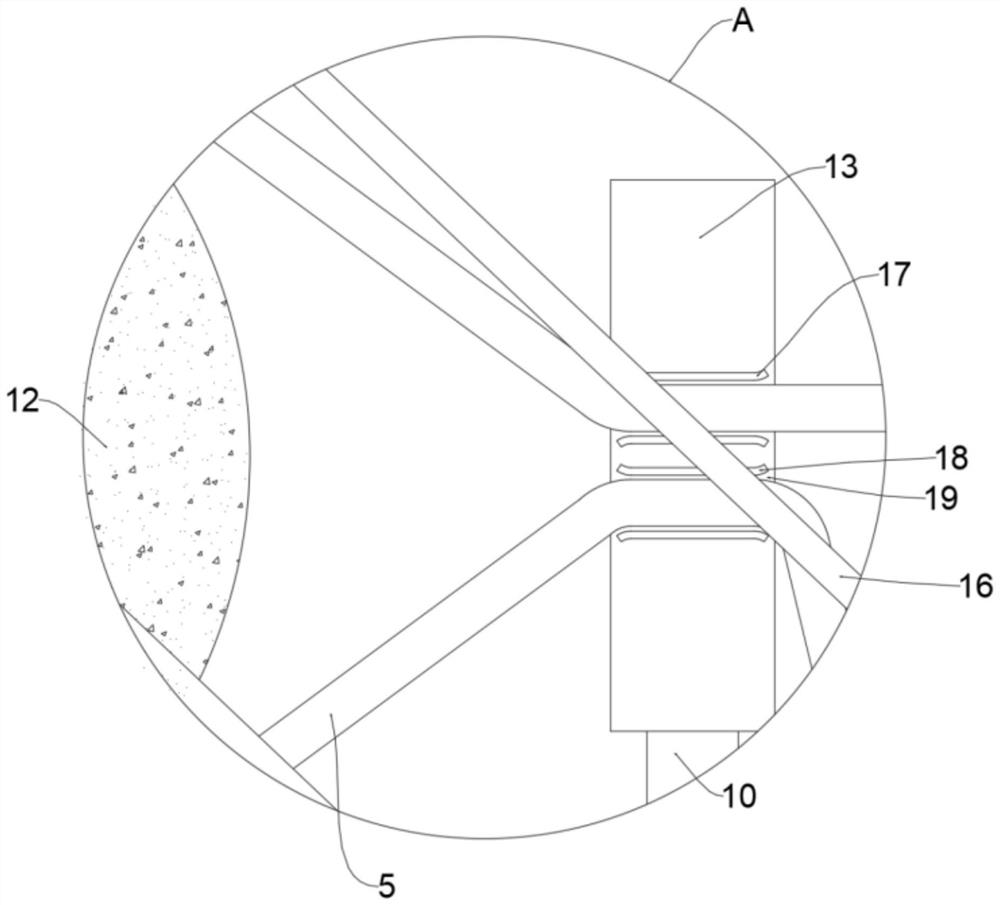

[0034] see Figure 1-6 , an embodiment provided by the present invention: a sanding treatment device and method based on a combined carbon fiber sanding machine, comprising a device casing 1, a discharge port 2 is provided on one side of the interior of the device casing 1, and the device casing 1 The other side of the interior is provided with a feeding port 3 , and two pairs of first transmission blocks 6 are provided inside the feeding port 3 and the discharging port 2 , and both ends of the first transmission block 6 are rotatably connected with the device shell 1 . :

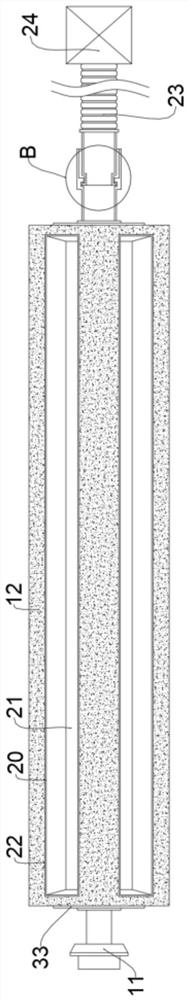

[0035] The third transmission block 11 is arranged on both sides ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap