Board splicing process and device for circuit board production

A circuit board and jigsaw technology, which is applied to the assembly of printed circuits with electrical components, printed circuits, and printed circuit manufacturing. The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

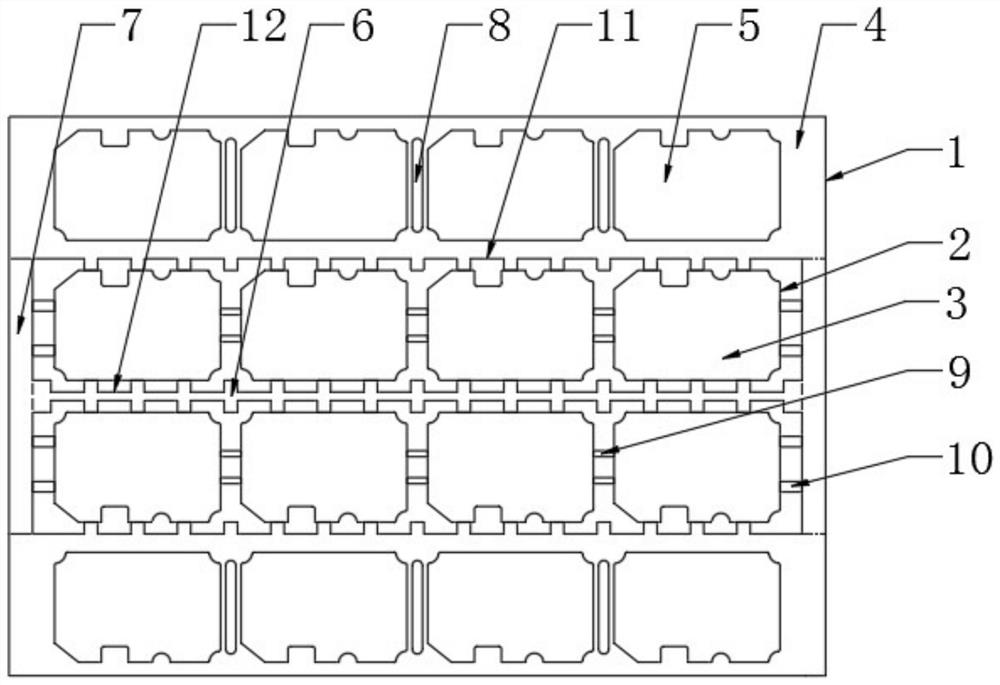

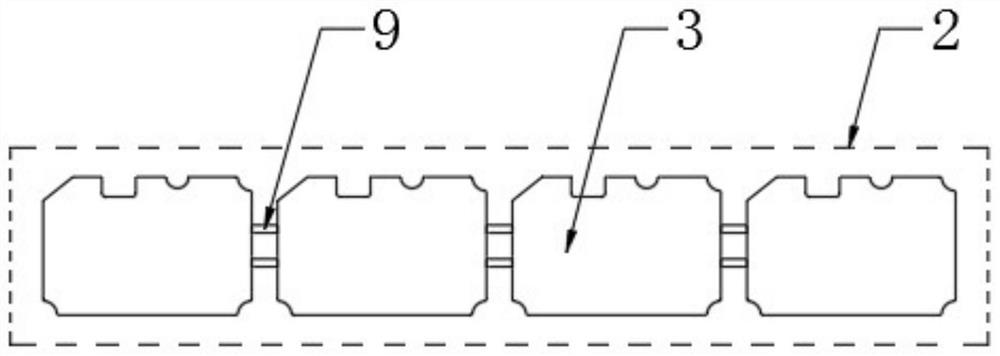

[0033] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

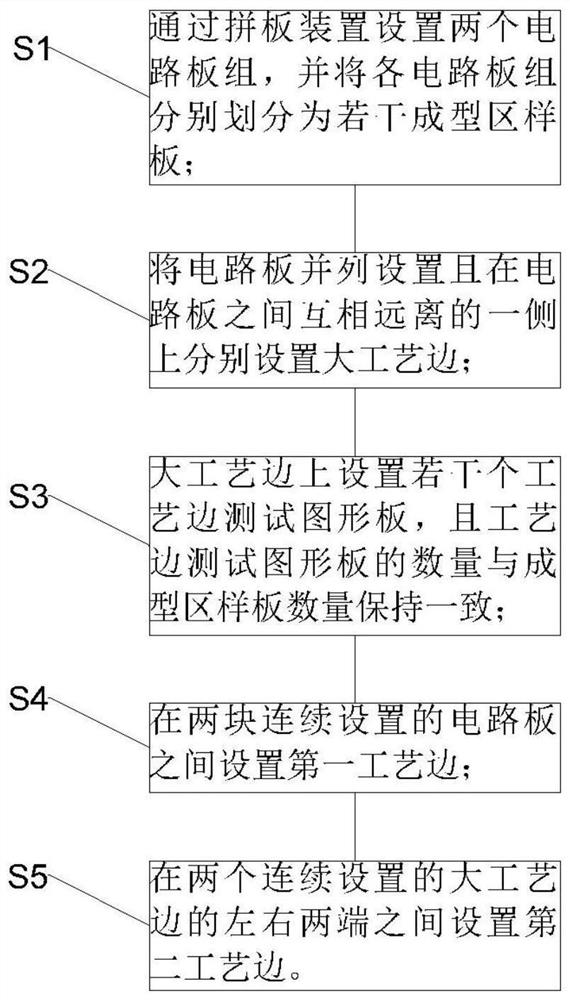

[0034] The present invention provides such as Figure 1-5 A paneling process and device for circuit board production shown, wherein a paneling process for circuit board production includes the following steps:

[0035] S1. Set up two circuit board groups through a jiggering device, and divide each circuit board group into several molding area templates;

[0036] S2, arranging the circuit boards side by side and setting large process edges on the sides of the circuit boards away from each other;

[0037] S3. A number of process edge test graphics boards are set on the large process edge, and the number of process edge test graphics boards is consistent with the number of samples in the molding area;

[0038] S4, setting a first process edge between two...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap