Double-frequency self-excited vibration type double-wing break shovel

A self-excited vibration and soil loosening shovel technology, applied in the field of soil loosening shovels, can solve the problems of not being able to adapt to different soil properties, achieve the effect of reducing working resistance and wide selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] Referring to the accompanying drawings, the specific embodiments are as follows:

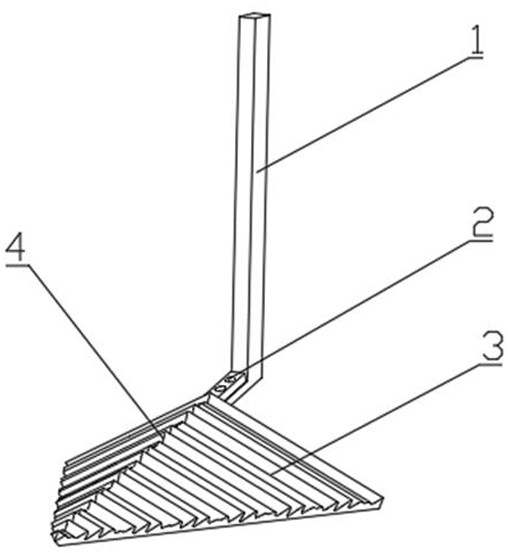

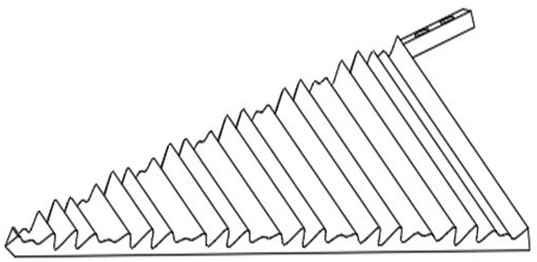

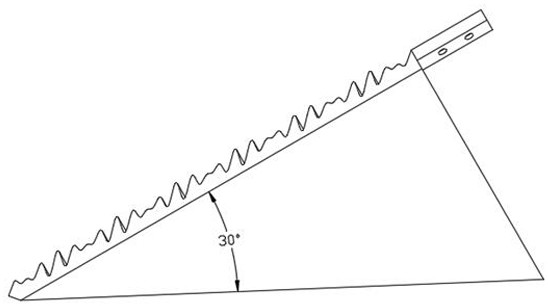

[0016] A dual-frequency self-excited vibration type double-wing ripper, characterized in that it comprises a shovel handle 1 and a ripper body, the ripper body includes two shovel wings 3, the shovel wings 3 are in the shape of a right-angled triangle, and the two shovel wings 3 The shape of the two shovel wings 3 is the same, and the edges of a right-angle side of the same length on the two shovel wings 3 are aligned and connected to form a shovel edge 4 extending in the bulldozing direction in the middle of the shovel body. The bottom surface of the ripping shovel body is formed in cooperation with the bottom surface of the ripping shovel body. The bottom surface of the ripping shovel body is arranged in the horizontal direction. The rear end of the blade 4 in the bulldozing direction. The rear end of the body of the ripper along the bulldozing direction is provided with a connecting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com