Full-automatic multi-pulp adding device

An adding device and fully automatic technology, which is applied in the field of beverage processing, can solve the problems of affecting the taste, not being able to add pulp, and not being able to realize diversified pulp addition, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

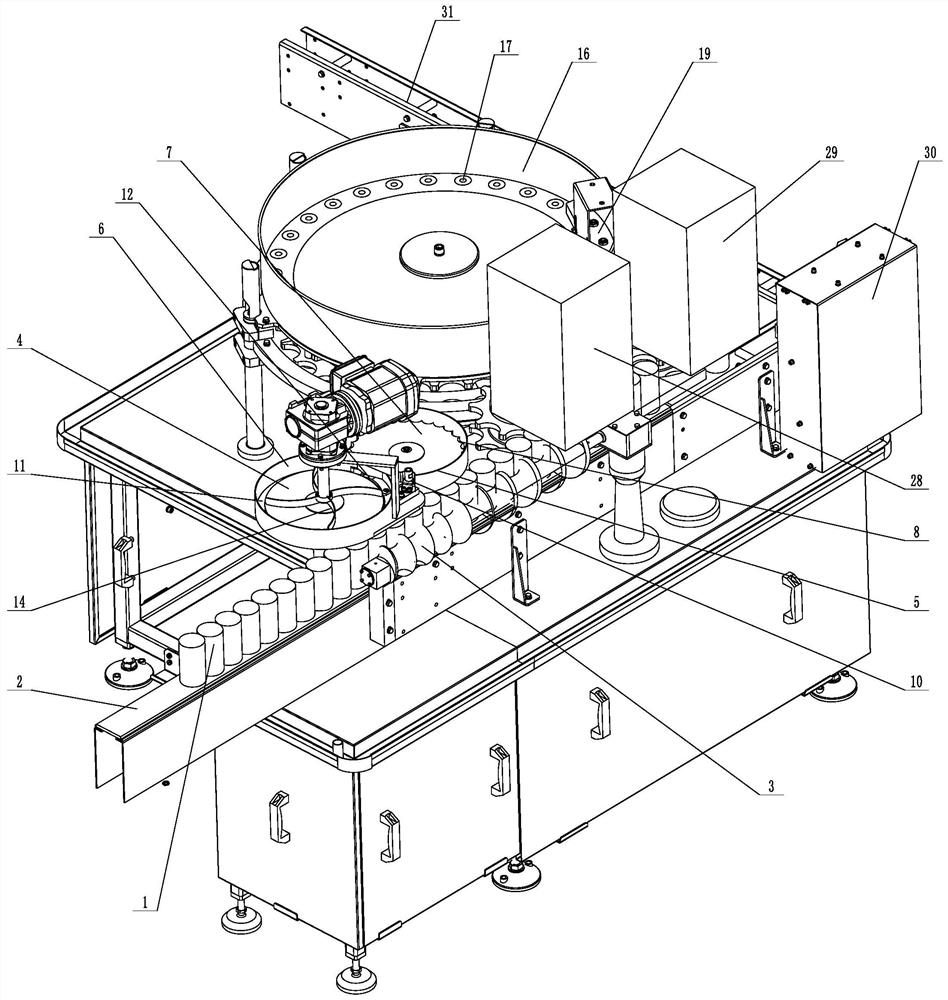

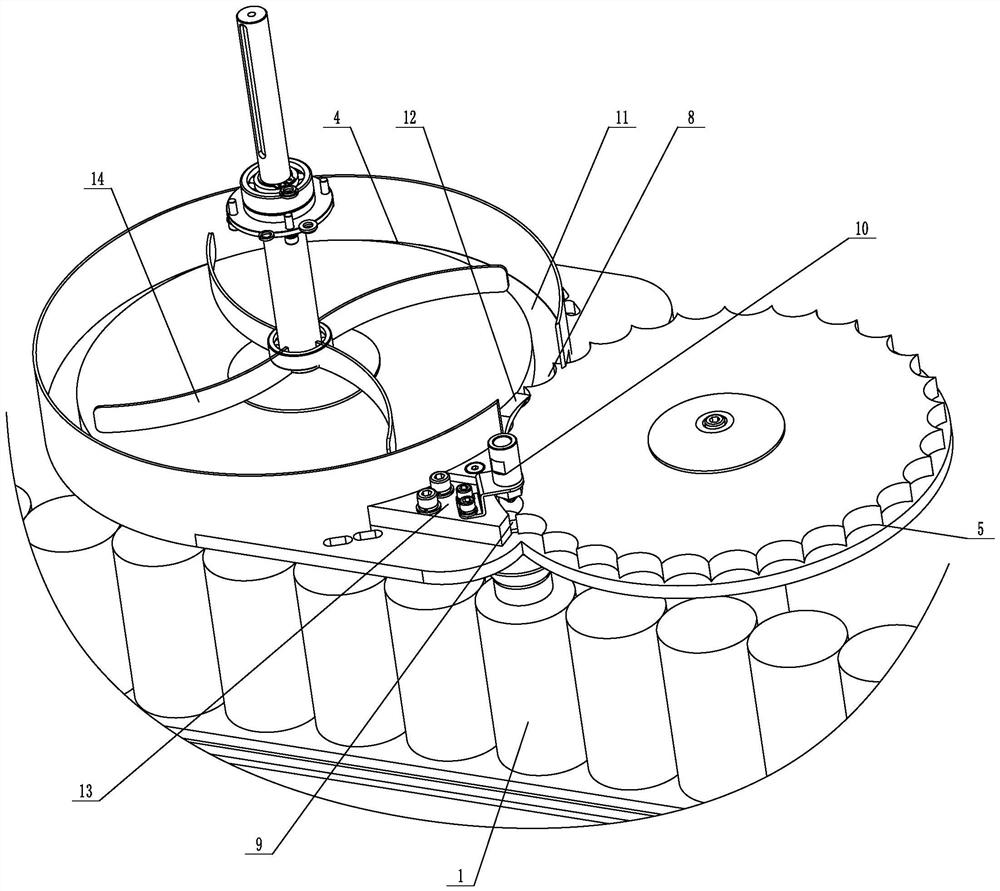

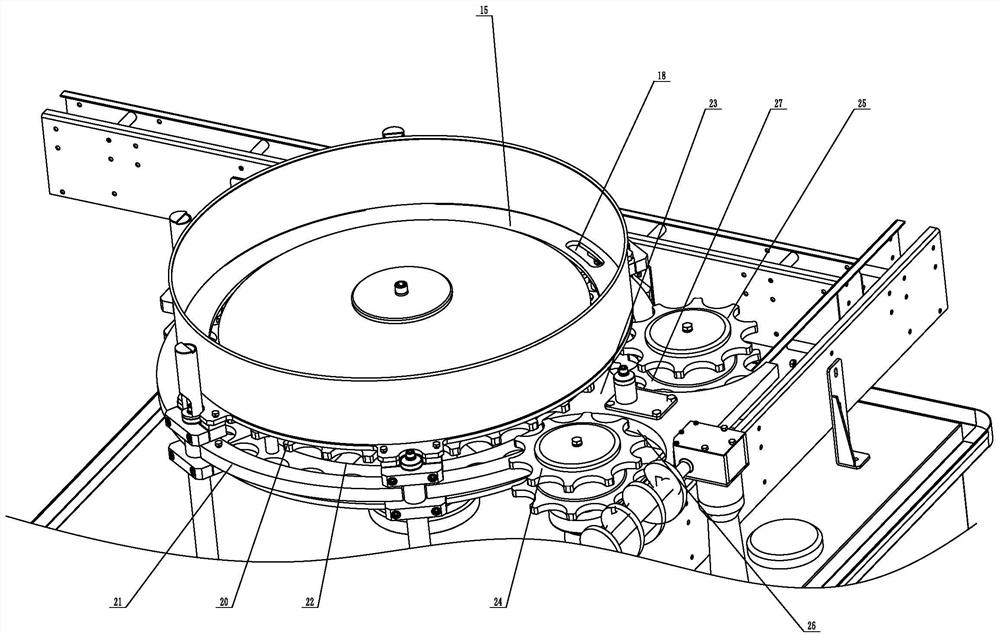

[0035] Example: an automatic multi-fruit pulp adding device (see attached figure 1 to the attached Figure 4 ), including the conveying mechanism, the first adding mechanism, and the second adding mechanism. The conveying mechanism, the first adding mechanism and the second adding mechanism are all installed on the frame.

[0036] The conveying mechanism is used for conveying the bottle body 1; the conveying mechanism includes a bottle body conveying belt 2 and a bottle feeding screw 3, and the bottle feeding screw is installed above the bottle body conveying belt. The feeding screw is driven by the motor, and the axis direction of the feeding screw is parallel to the conveying direction of the bottle body.

[0037] The first adding mechanism is used to add fresh fruit pulp, including a cutting plate 4 and a quantitative plate 5. The edge of the cutting plate and the quantitative plate are fixedly installed with side plates 6, and a turntable 7 is installed in the quantitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com