Device for preparing continuous coating solution in controlled-release fertilizer production

A controlled-release fertilizer and coating technology, which is applied in transportation and packaging, mixers with rotating stirring devices, dissolution, etc., can solve the problem of unsuitable large-scale industrial production of coated controlled-release fertilizers, poor automation, and slow feeding speed and other problems, to achieve the effect of removing insoluble matter, improving quality, and improving preparation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

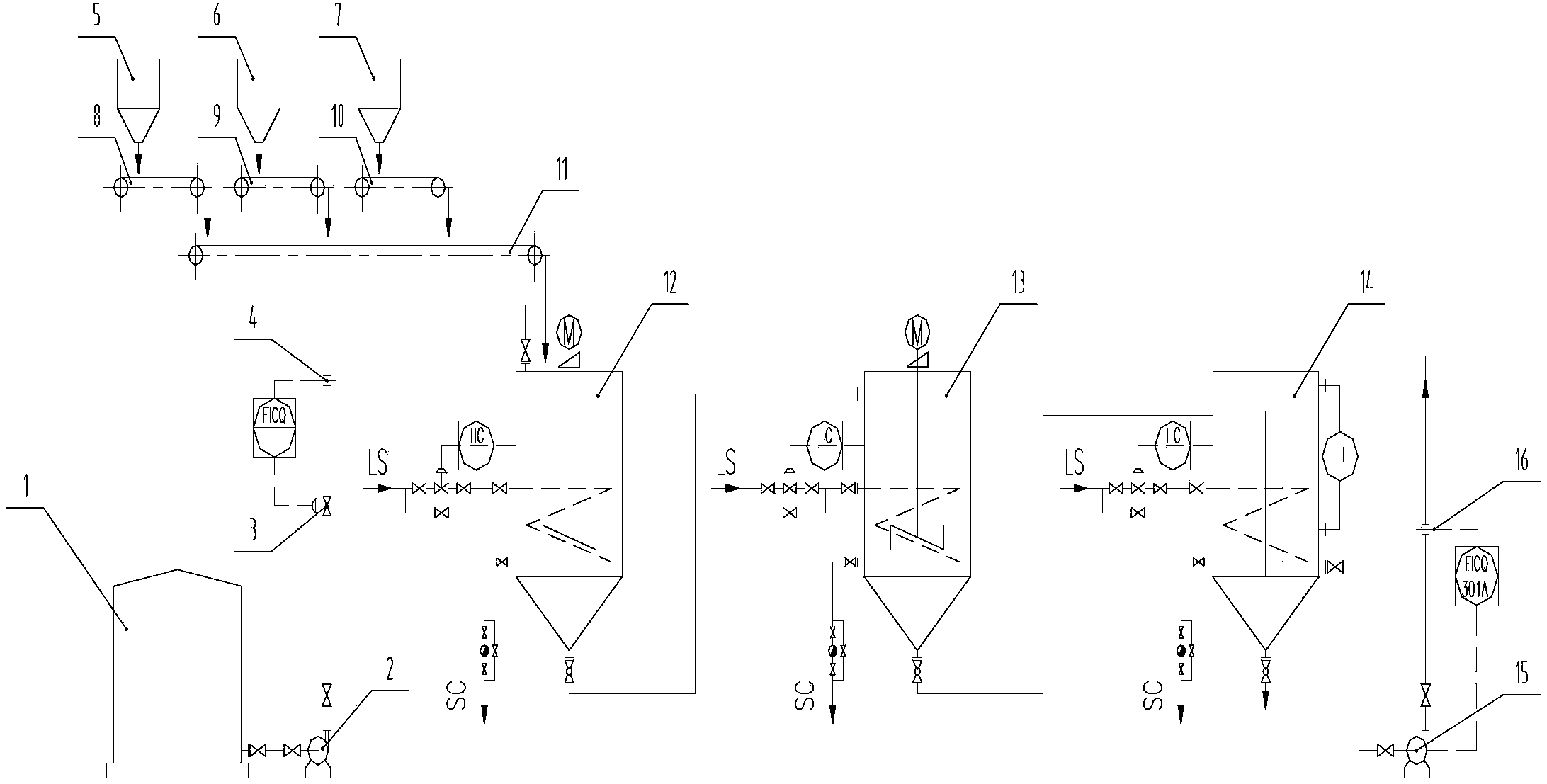

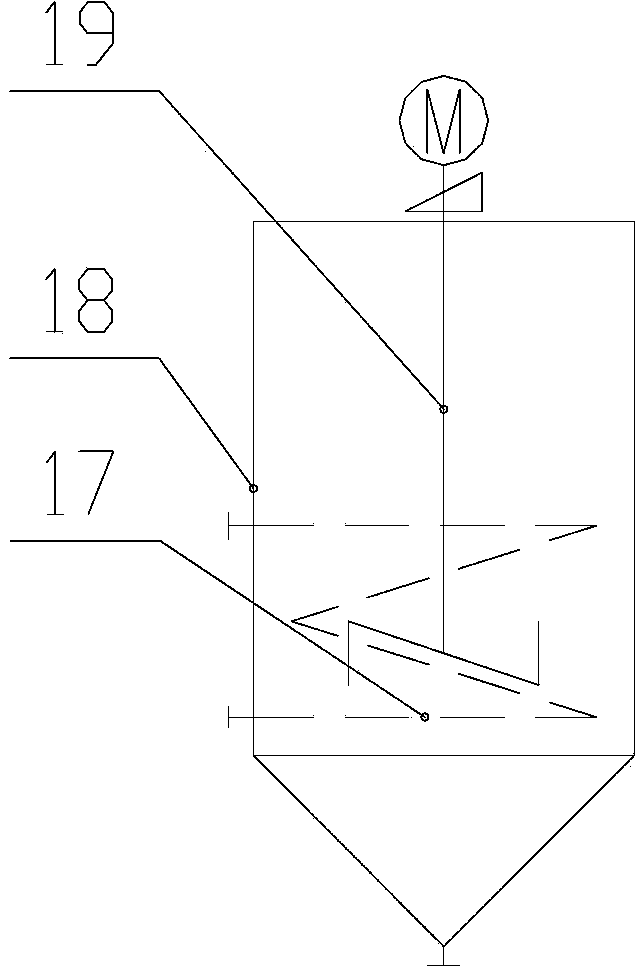

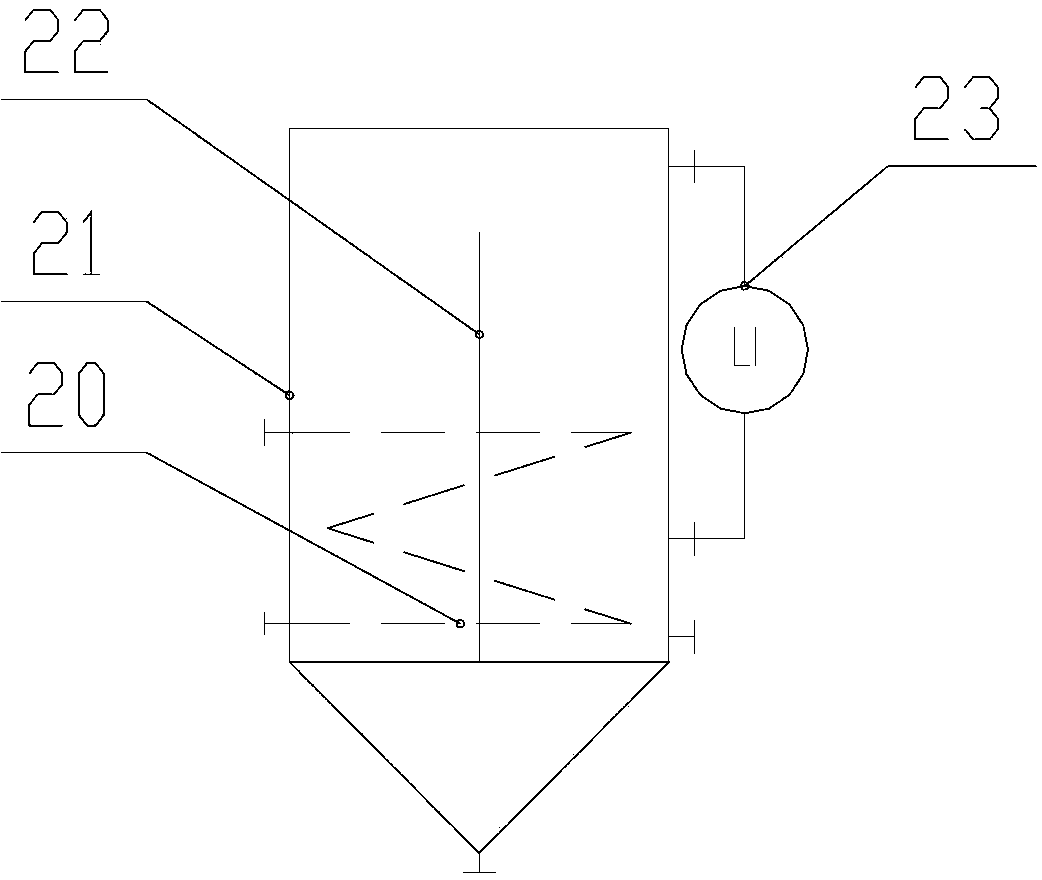

[0030] like figure 1 As shown, a continuous coating solution preparation device in the production of controlled-release fertilizers includes a raw material silo one 5, a raw material silo two 6, a raw material silo three 7, a weighing scale 8 arranged at the bottom of the raw material silo one 5, Measuring scale 2 9 arranged at the bottom of raw material silo 2 6, measuring scale 3 10 arranged at the bottom of raw material silo 3 7, mixing conveyor 11, primary dissolving tank 12, secondary dissolving tank 13, two-phase separator 14 , liquid pump 2 and liquid pump 15, solvent storage tank 1; The outlet of raw material silo links to each other with mixing conveyor 11, and mixing conveyor 11 links to each other with the feed inlet of primary dissolving tank 12, and the liquid of primary dissolving tank 12 The outlet is connected to the feed port of the secondary dissolution tank 13, the liquid outlet of the secondary dissolution tank 13 is connected to the feed port of the two-ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com