Vacuum Die Casting System

A vacuum die-casting and die-casting machine technology, applied in the field of vacuum die-casting systems, can solve the problems of increased production cost of protective gas, increased product porosity, increased production yield, etc., to improve appearance quality, reduce time spent, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

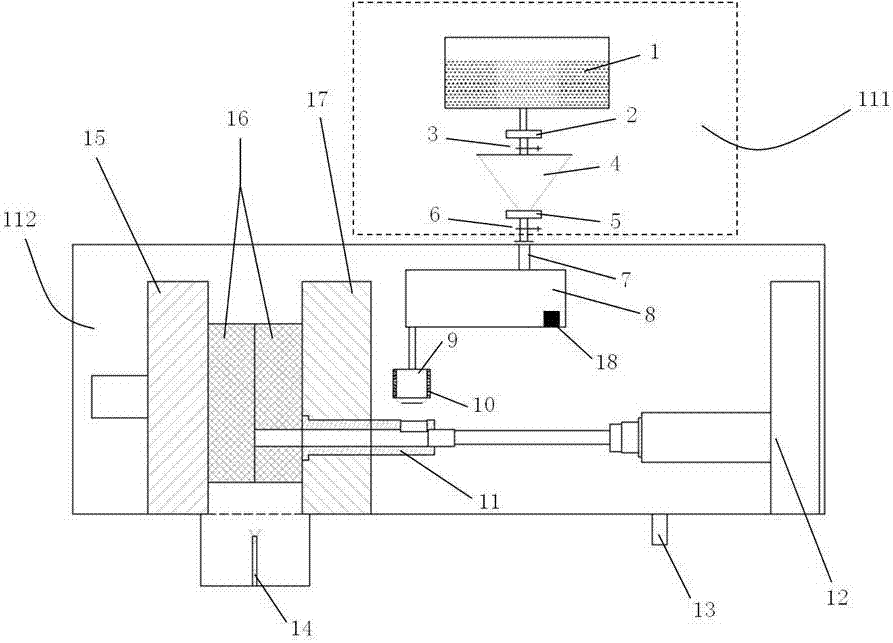

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] Embodiment The structure and usage method of the vacuum die-casting system in the present invention will be described by adopting the die-casting process of amorphous alloy.

[0035] As shown in the drawings, the vacuum die-casting system includes an externally controlled feeding system 111, a vacuum chamber body 112 and a vacuum die-casting machine. The main components of the vacuum die-casting machine include a die-casting machine storage mechanism 8, a crucible 9, a heating device 10, a Cup 11, injection mechanism 12, air extraction hole 13, pick-up device 14, movable template 15, molding die 16, fixed template 17.

[0036] A large amount of amorphous alloy die-casting raw materials are loaded in the material storage box 1, and the die-casting raw materials of amorphous alloys can be in powder form or in small granular form, and the particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com