Tamping stroke adjustment

A technology of adjusting mechanism and repairing machine, which is applied in the direction of road, construction, road repair, etc. It can solve the problems of space occupied by the screed, complex structure of the toggle mechanism, and difficulty in directly installing and adjusting the actuation or driving of the transmission device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

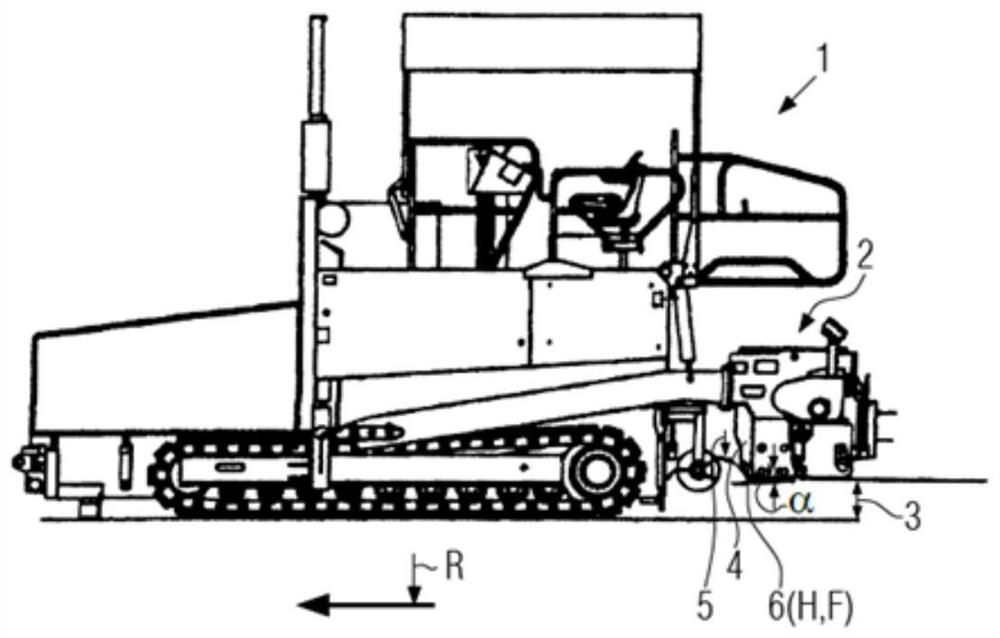

[0060] figure 1 A road finishing machine 1 is shown with a screed 2 for making a paving layer 3 in the direction of travel R of the paving. The screed 2 has at least one compaction unit 4 for pre-compacting the paving material 5 supplied to the screed 2 . The compaction unit 4 comprises a tamper bar 6 which can be driven with a variable ramming stroke H and / or a variable frequency F to pre-compact the paving material 5 supplied to the screed 2 .

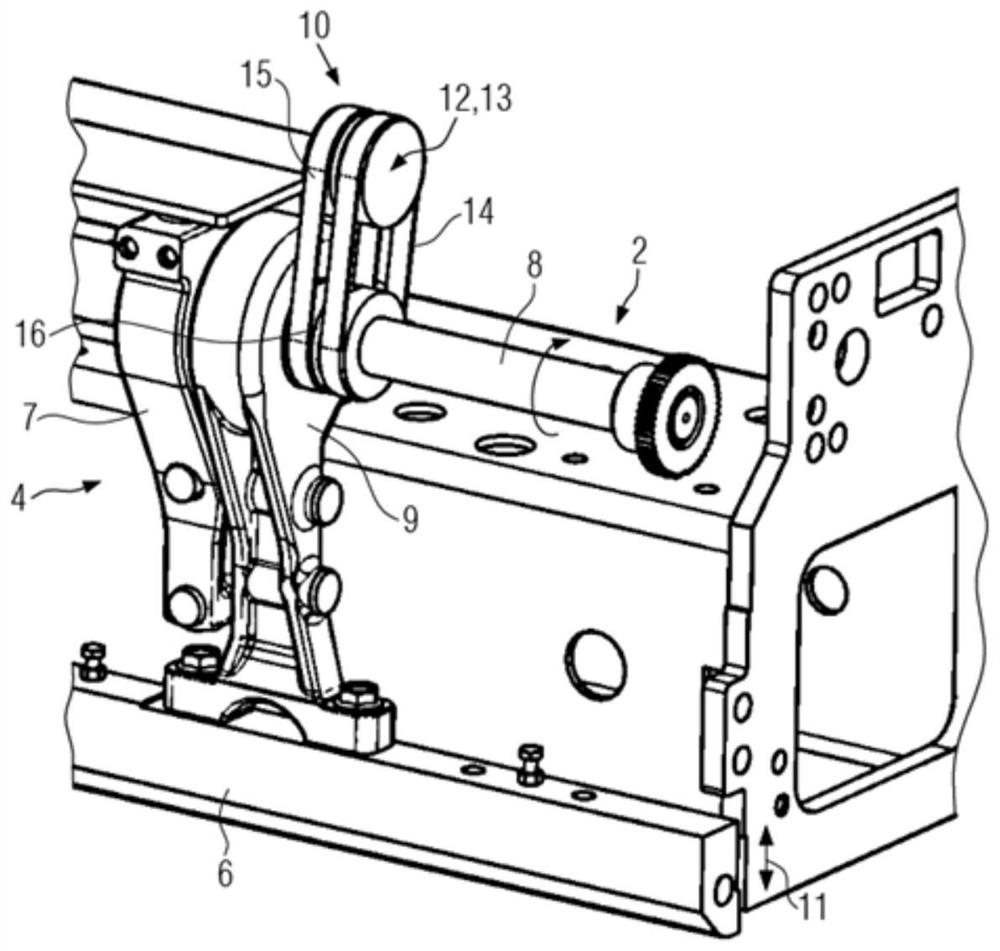

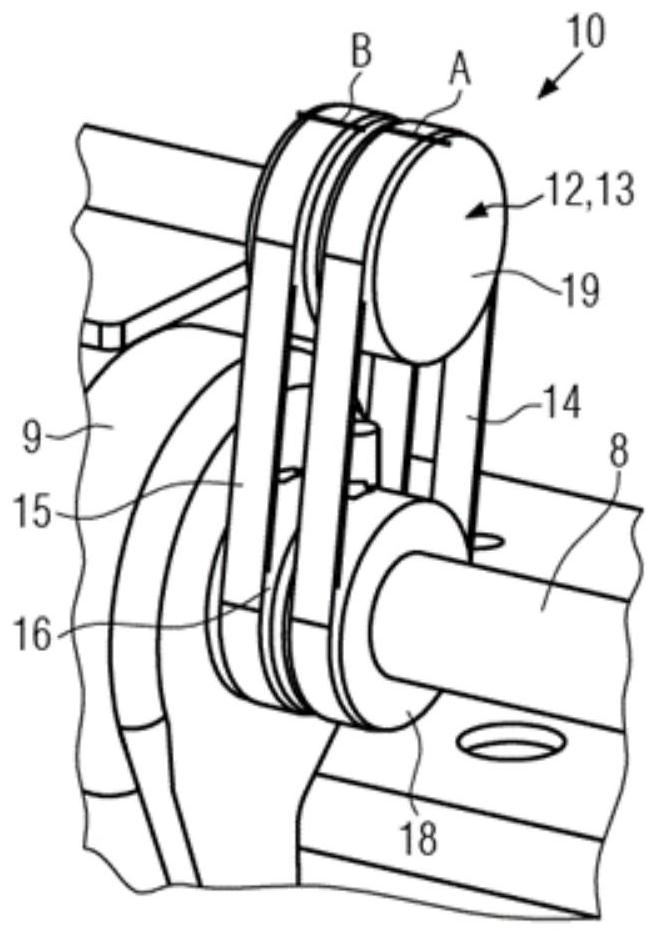

[0061] figure 2 The compaction unit 4 is shown alone in an enlarged perspective view. The compaction unit 4 has a bearing support 7 fixed to the screed body and an eccentric shaft 8 rotatably mounted thereon. The eccentric shaft 8 drives the connecting rod 9, and the tamper bar 6 is fixed on the connecting rod 9.

[0062] figure 2 Also shown is an adjustment mechanism 10 that is rotationally driven by the eccentric shaft 8 . The adjustment mechanism 10 can be actuated to set a variable desired ramming stroke 11 for the tamper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com