Intelligent deviation-rectifying laser die-cutting machine

A die-cutting machine and laser technology, used in laser welding equipment, manufacturing tools, transportation and packaging, etc., can solve the problems of high tension in the bending part, affecting processing positioning, unable to adjust the initial state, etc., to achieve pressure balance, improve anti- curling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

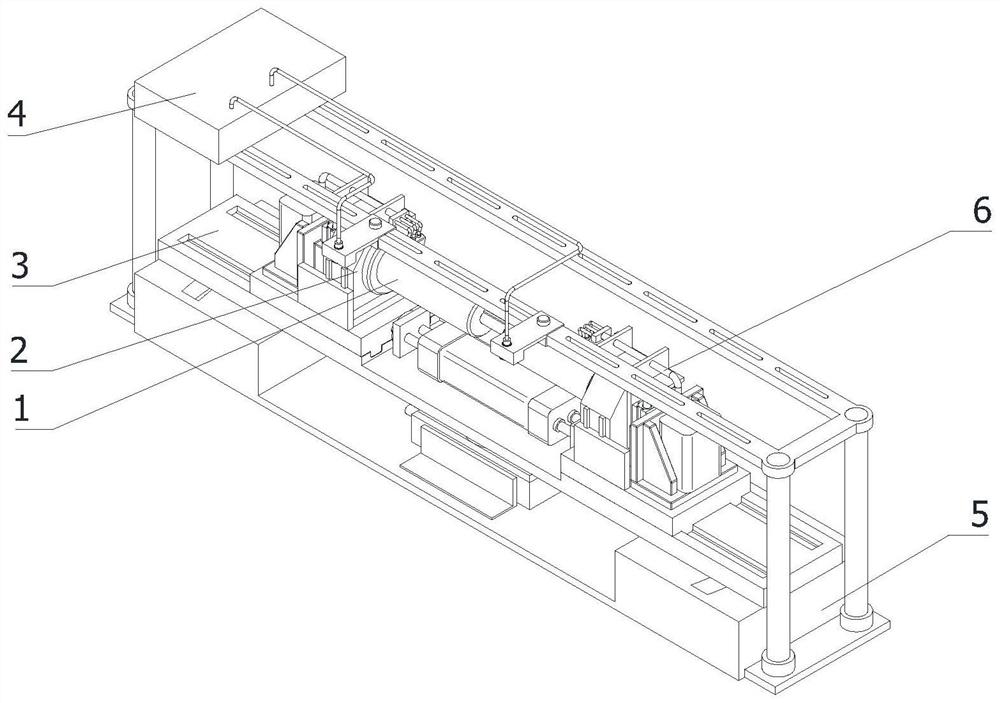

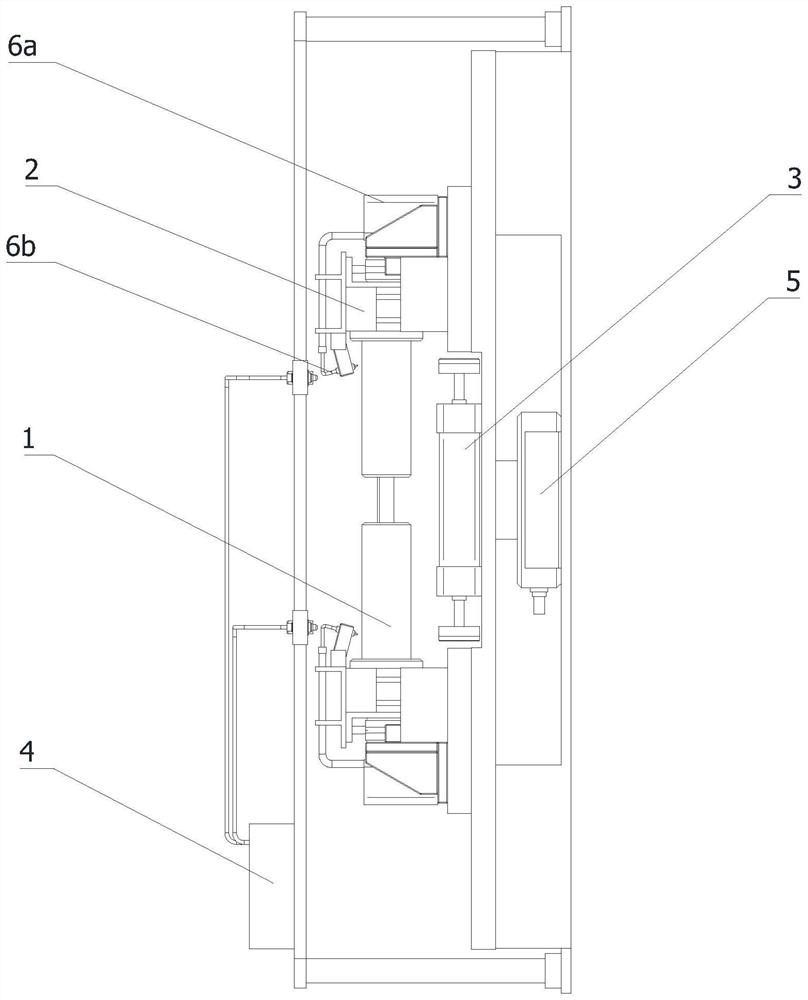

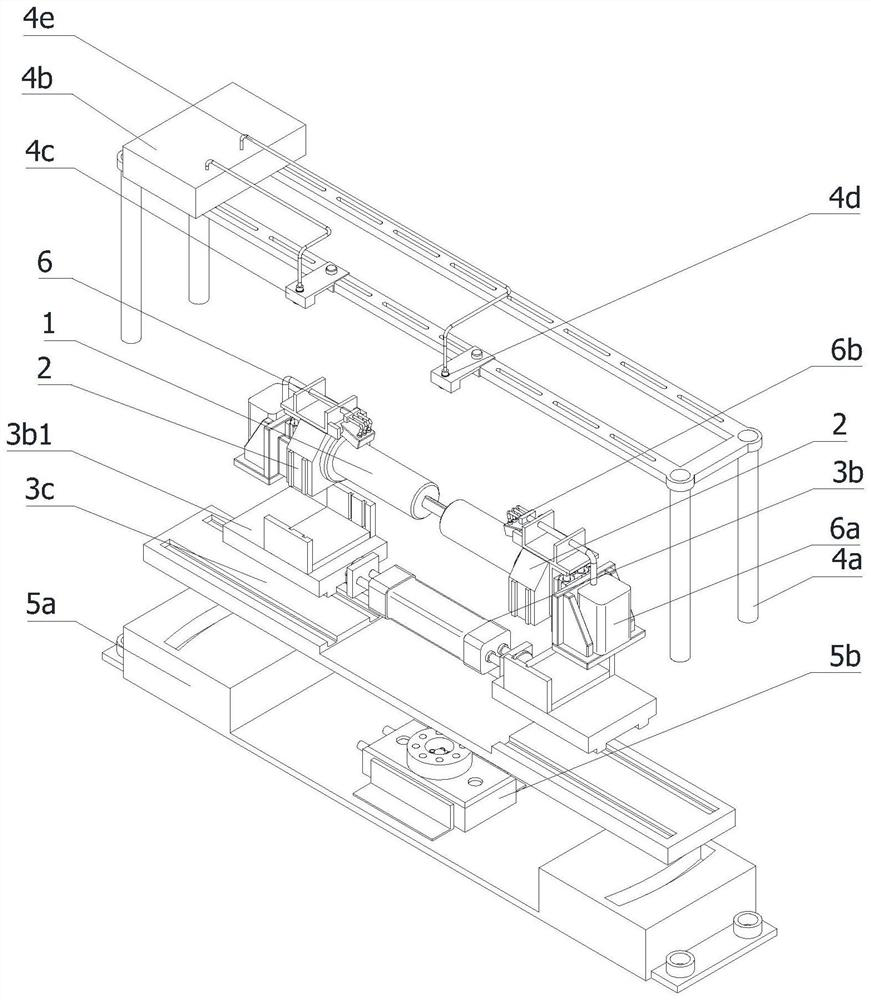

[0041] Such as Figure 1 to Figure 4 As shown, this application provides:

[0042]A laser die-cutting machine with intelligent deviation correction, including a rewinding and unwinding unit for loading materials, a traction unit that drives materials to move, a deviation correction unit that places material movement deviations, and a laser cutting unit. The deviation correction unit includes a horizontal The deviation correction roller 1 is placed, the axis of the deviation correction roller 1 is perpendicular to the direction of material movement, the two ends of the deviation correction roller 1 are installed in the installation bearing seat 2, and the installation bearing seat 2 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com