Full-independent control intelligent high-speed embroidery machine head

An independent control and intelligent technology, which is applied to embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc., can solve the problems of limited adaptability of embroidery machines, and achieve the goals of improving machine working efficiency, enhancing adaptability, and reducing mechanical vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

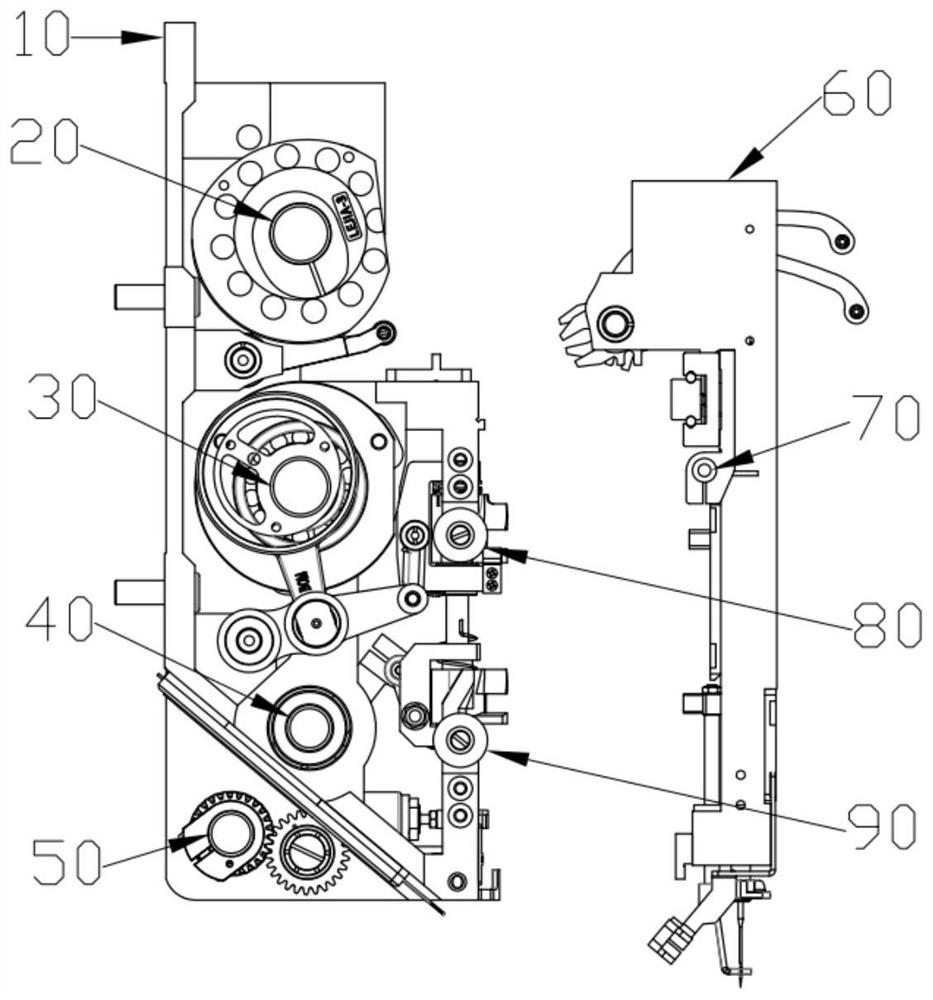

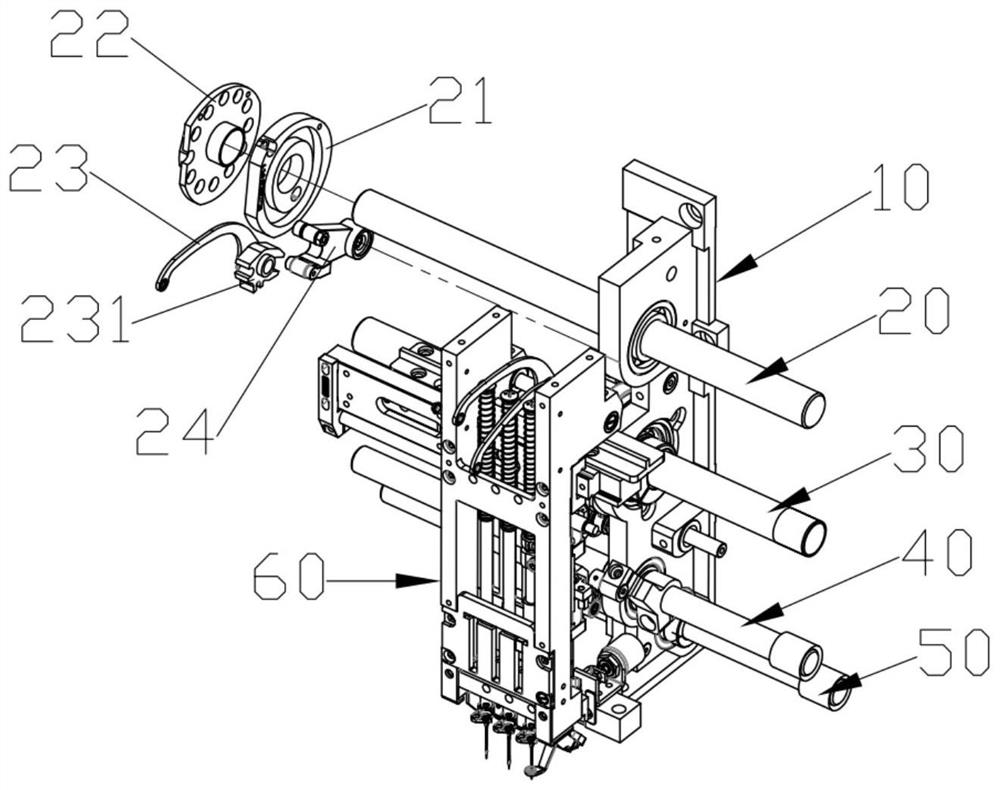

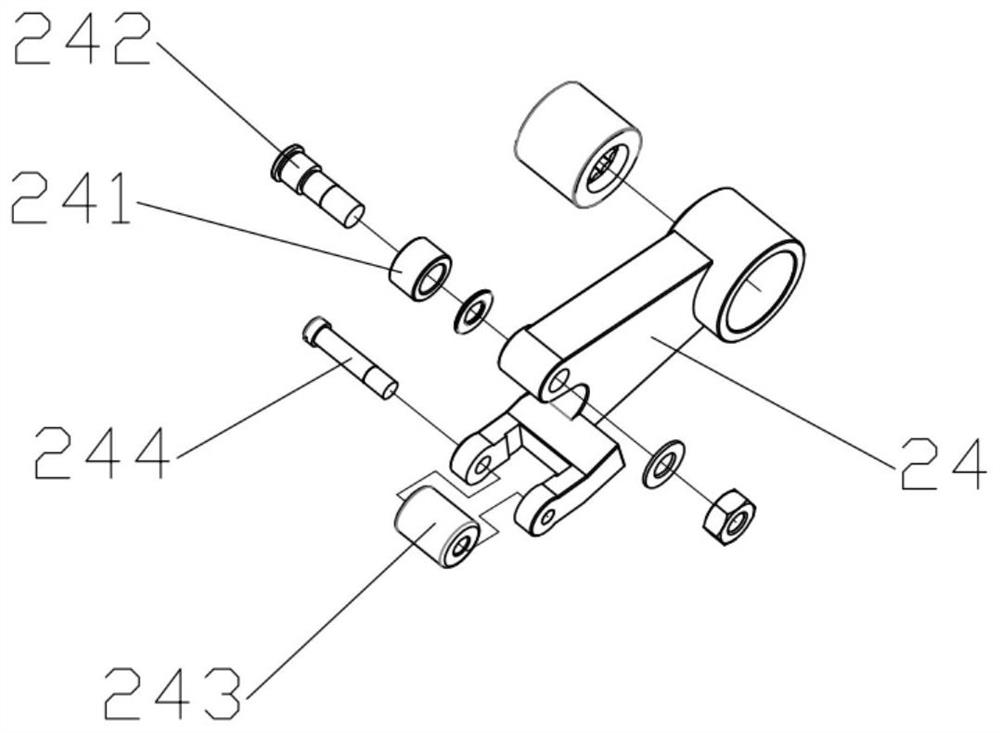

[0030] like Figure 1 to Figure 10 As shown, a fully independently controlled intelligent high-speed embroidery head includes a head part and a needle bar frame part; the head part includes a casing 10; the needle bar frame part includes a needle bar frame 60; 70 is arranged on the right side of the casing 10 to move forward and backward; the upper end of the needle bar frame 60 swings and is provided with a number of thread take-up levers 23 that are evenly distributed before and after, and the lower part is vertically moved with a number of needle bars that are evenly distributed back and forth. A number of presser feet 46 evenly distributed in the front and back; the casing 10 is rotatably provided with the thread take-up main shaft 20, the needle bar main shaft 30, the presser foot main shaft 40 and the hook-knife main shaft 50 arranged from top to bottom; the lower end of the casing 10 is arranged from the left to the left A hook knife 57 is provided on the right inclined d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com