Cylinder assembly and clothes processing device with same

A technology for clothes processing devices and cylinder components, which is applied to washing devices, household utensils, and household clothes dryers. The effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

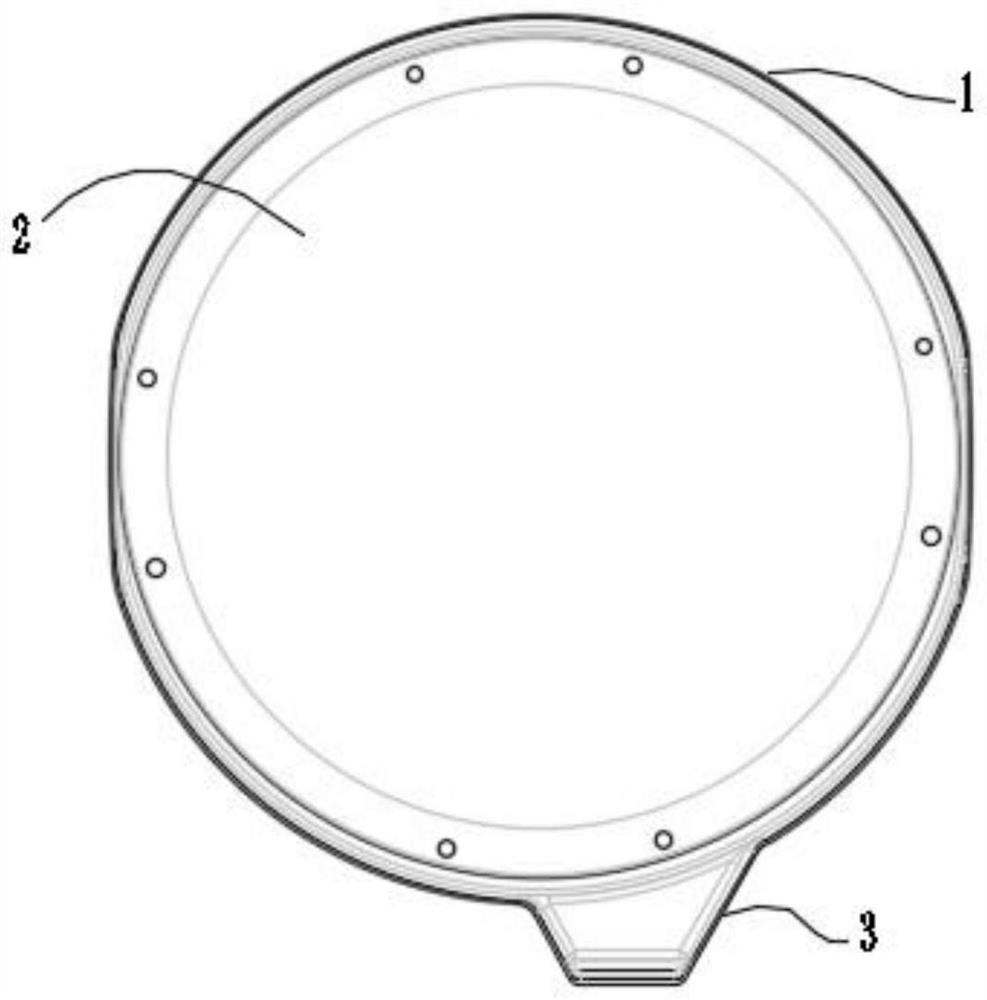

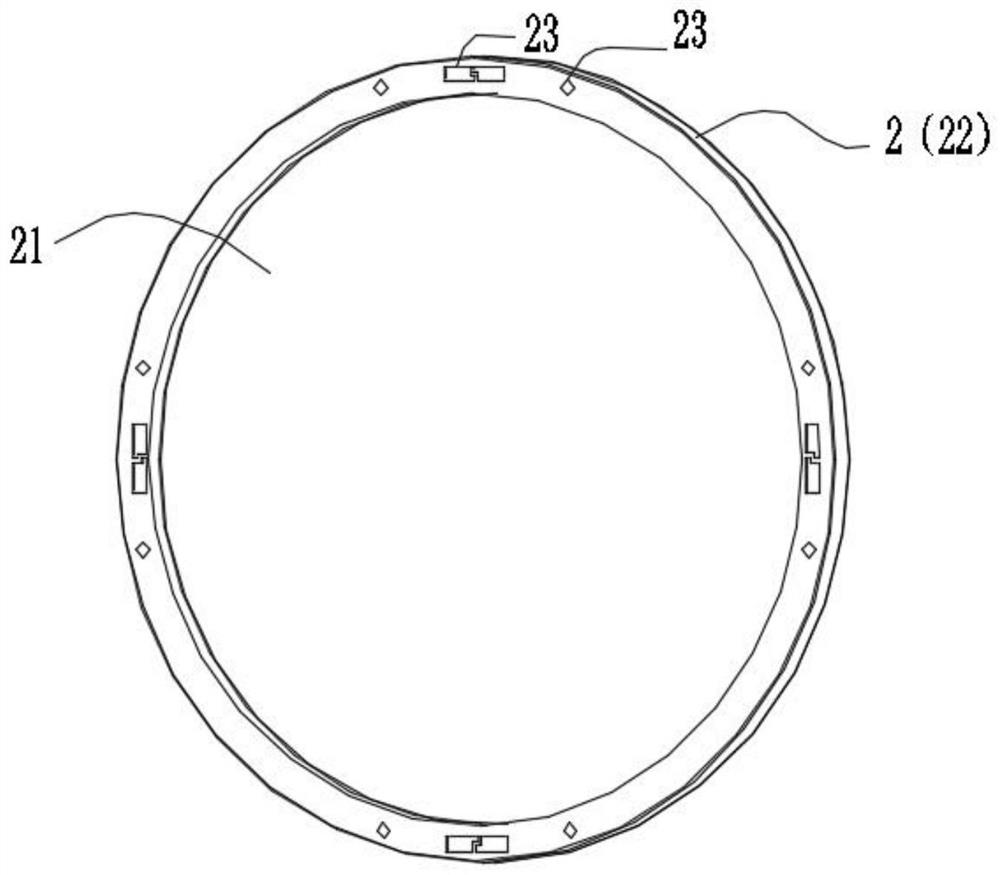

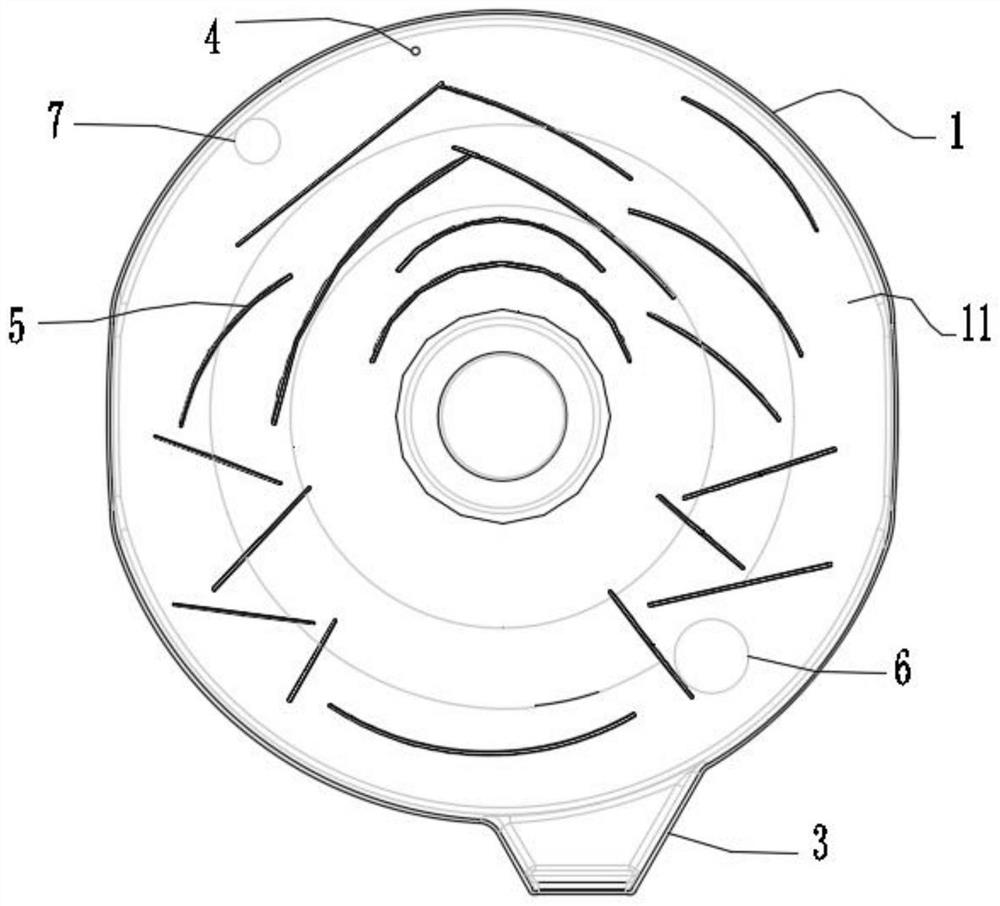

[0026] see in combination Figure 1-4 As shown, a barrel assembly includes a rear barrel structure 1 and a partition structure 2, the rear barrel structure 1 has an inner surface 11; the cooling liquid can flow on the inner surface 11 to form a condensation surface; the partition structure 2 is arranged on the inner surface 11, and form a condensation cavity with the inner surface 11; the fluid to be condensed can exchange heat with the condensation cavity through the partition structure 2. When drying in the present application, the condensation of the rear cylinder and the condensation of the rear air duct are used at the same time. For the condensation part of the rear cylinder, a partition structure 2 is arranged between the rear cylinder and the inner cylinder, the condensed water flows between the inner surface 11 of the rear cylinder and the partition structure 2, and the hot air and the condensed water are separated by the partition structure 2 for condensation and hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com