Sleeve matching method based on arm geometric model

A geometric model and arm technology, applied in the field of sleeve matching based on the geometric model of the arm, can solve the problems of limited success rate of plate making, poor data rationality, complex process, etc., to improve sleeve matching ability and efficiency, reduce research and development costs, The effect of simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A method for arranging sleeves based on the geometric model of the arm of the present invention comprises the following steps:

[0059] Step S1, select a suitable model, measure and record the prototype sign data of the upper body of the model. Mainly: shoulder slope 20°, bust 86CM, waist 68CM, back length 39CM, front waist length 41.8CM, back waist length 41CM, neck circumference 33CM, shoulder width 38CM, front armpit length 7.8CM, back The armpit length is 9.5CM, the chest width is 32.6CM, the back width is 33.4CM, the arm length is 55, the arm circumference is 26.5CM, the elbow circumference is 22CM, and the wrist circumference is 15CM. Preferably, in order to accurately measure the size of the body part, it is necessary to mark the basic part line before measuring.

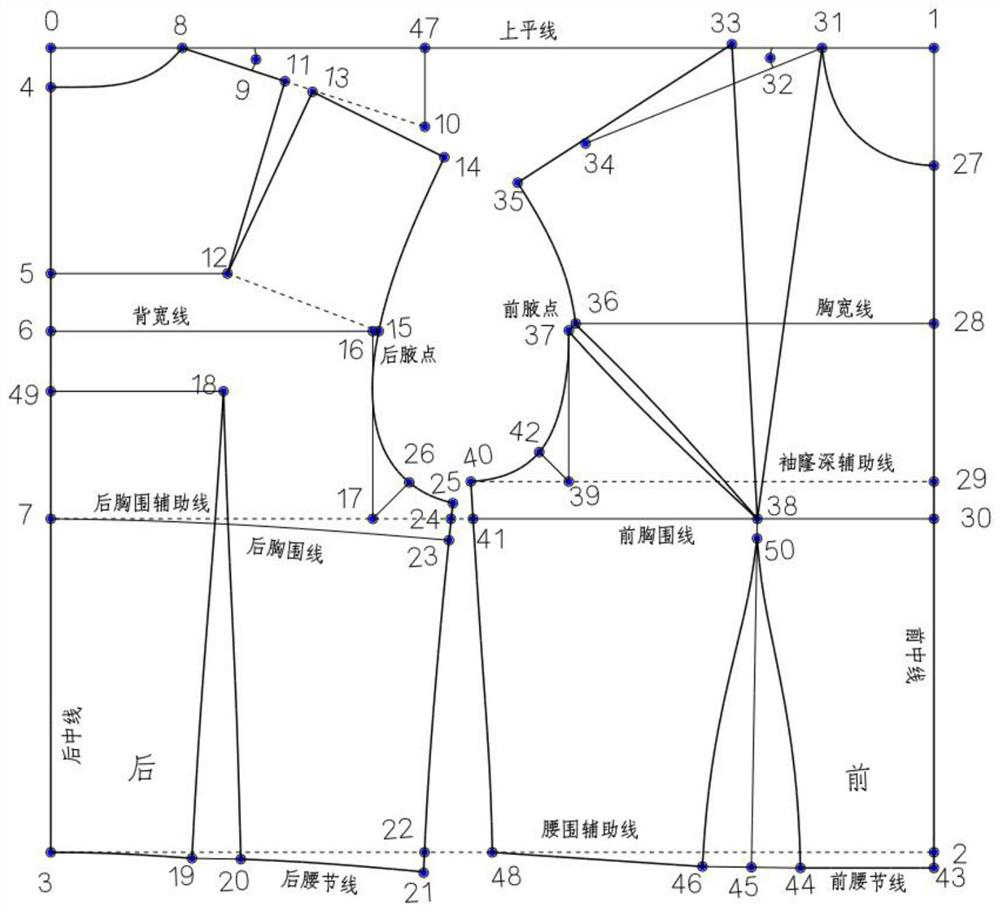

[0060] Step S2, see figure 1 , based on the body upper body prototype sign data and body surface features measured in step S1, combined with the actual plate-making operability, draw a body prototype...

Embodiment 2

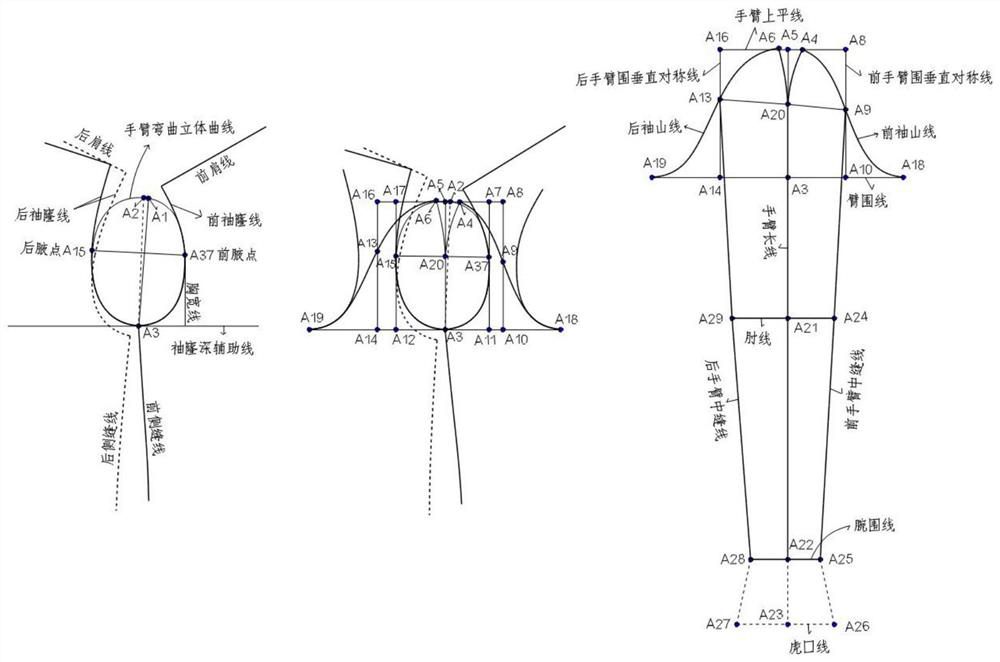

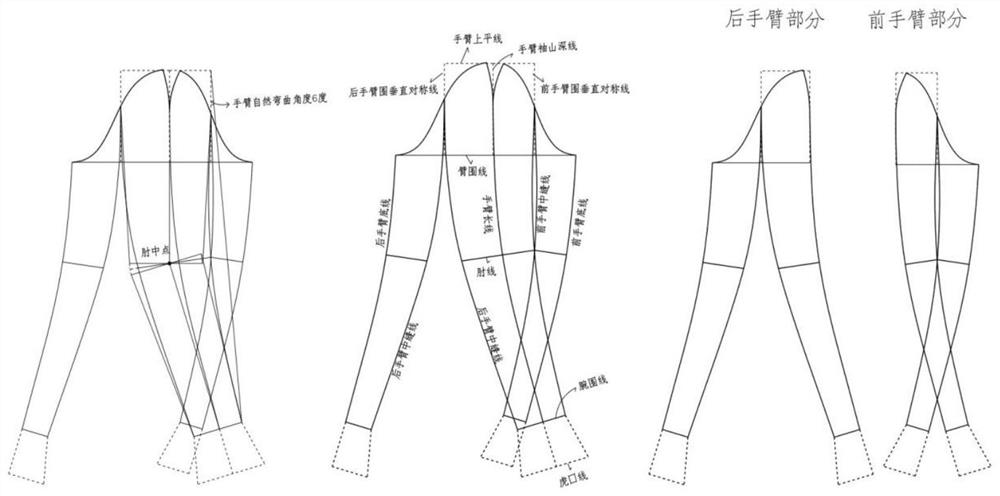

[0089] see Figure 4 , on the basis of the first embodiment, the difference between this embodiment and the first embodiment is that step S4 also includes the establishment of a one-piece sleeve arm geometric model, based on the obtained one-piece arm geometric model, using the module splicing and overlapping , based on the middle suture of the front arm and its copy line, transfer the part of the front forearm to be spliced with the middle suture of the forearm, and transfer the part of the back forearm to the middle seam of the back arm based on the middle suture of the back arm and its copy line Line splicing, then adjust the overlapping part of the front arm and the open part of the rear arm to unfold and overlap, adjust to form an elbow dimple at the elbow line of the rear arm, and draw the bottom line of the front arm, the bottom line of the rear arm, the middle seam of the front arm, The middle suture line of the back arm, the long line of the arm, and the tiger's mou...

Embodiment 3

[0096] see Figure 5 , on the basis of Embodiment 1, the difference between this embodiment and Embodiment 1 is that in this embodiment, step S4 is based on the basic arm plane geometric model obtained in step S3, and a straight arm geometric model is established; The arm length line is the dividing line, which divides the two sides of the straight arm geometric model into the fore-arm geometric model and the rear-arm geometric model.

[0097] Preferably, the establishment of the straight arm geometric model includes, on the basic arm plane geometric model obtained in step S3, rotating the sleeve mountain line close to the arm, so that the vertices of the front sleeve mountain line and the back sleeve mountain line intersect with the long line of the arm, according to the human body. The arm body shape features extend the elbow line, the wrist circumference line, and the tiger's mouth line to both sides, and make lines to connect the endpoints on both sides respectively to bec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com