High-efficiency gold reflective film suitable for 7.5-12 μm wave band and preparation method thereof

A reflective film and high-efficiency technology, applied in mirrors, instruments, optics, etc., can solve problems such as the inability to meet the requirements of new optical instruments, and achieve the effect of improving matching and combining ability, avoiding high rejection rate, and improving reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Select Φ25.4×3mm planar glass-ceramic substrate material, in the range of 7.5-12μm in the wave band, on the surface layer of one surface of the substrate, at 100°C, first coat Cr film and Au film layer, and then at 165°C Next, using the Kaufman ion source assisted deposition method, filling the argon gas flow rate of 3.0sccm, anode voltage 75V, cathode voltage 9V, cathode current 10A, the remaining 7 layers of infrared dielectric material film layers are plated to obtain the present invention. High-efficiency gold reflective coating for 7.5-12μm band.

[0021] The reflectance of the high-efficiency gold reflective film on the glass-ceramics substrate was measured, and the average reflectance of the high-efficiency gold reflective film on the glass-ceramics was measured to be 99.32%.

[0022] According to the national military standard GJB2485-1995, the part was subjected to adhesion force and damp heat measurement tests on the high-efficiency gold reflective film of gla...

Embodiment 2

[0024] Select a flat glass-ceramic substrate material of Φ50×5mm, and in the range of 7.5-12μm in the wave band, on the surface layer of one surface of the substrate, at 105°C, first coat Cr film and Au film layer, and then at 165°C, Adopt Kaufmann ion source assisted deposition method, fill in argon gas flow rate 3.0sccm, anode voltage 70V, cathode voltage 10V, cathode current 12A, plate the remaining 7 layers of infrared dielectric material film layers, obtain the applicable 7.5 layers of the present invention. - High-efficiency gold reflective coating in the 12μm band.

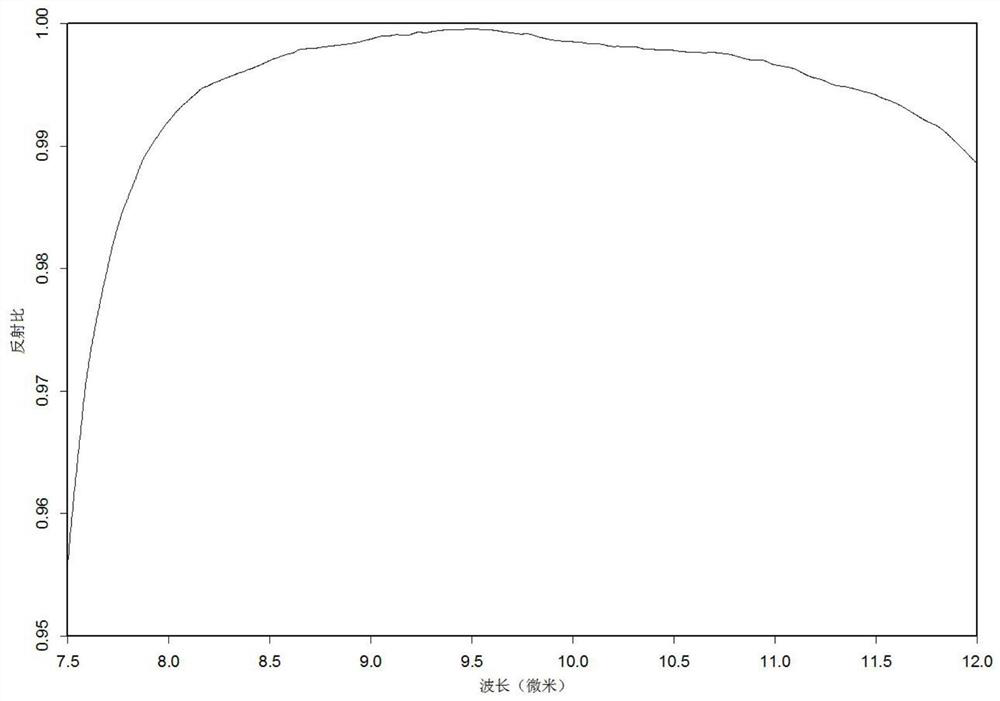

[0025] Such as figure 2 As shown, the reflectance of the high-efficiency gold reflective film on the glass-ceramics substrate was measured, and the average reflectance of the high-efficiency gold reflective film on the glass-ceramics was measured to be 99.50%.

[0026] According to the national military standard GJB2485-1995, the part was subjected to adhesion force and damp heat measurement tests on the ...

Embodiment 3

[0028] Select a 30×30mm flat glass-ceramic substrate material, and in the range of 7.5-12μm, in the range of 7.5-12μm, on the surface layer of one surface of the substrate, at 100°C, first coat the Cr film and the Au film layer, and then at 160°C, Adopt Kaufmann ion source assisted deposition method, fill in argon gas flow rate 3.0sccm, anode voltage 70V, cathode voltage 9.5V, cathode current 11A, plate remaining 7 layers of infrared dielectric material film layers, obtain described applicable of the present invention High-efficiency gold reflective coating in the 7.5-12μm band.

[0029] The reflectance of the high-efficiency gold reflective film on the glass-ceramics substrate was measured, and the average reflectance of the high-efficiency gold reflective film on the glass-ceramics was measured to be 99.45%.

[0030] According to the national military standard GJB2485-1995, the part was subjected to adhesion force and damp heat measurement tests on the high-efficiency gold r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com