Accurate batching and stirring mechanism for full-automatic production of quartz plates

A stirring mechanism, fully automatic technology, applied in mixers, mixers, dissolving and other directions with rotating stirring devices, can solve problems such as affecting the rapidity of stirring operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

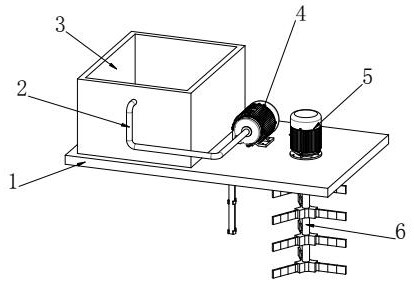

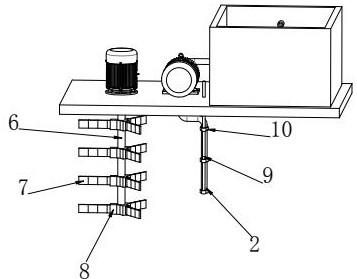

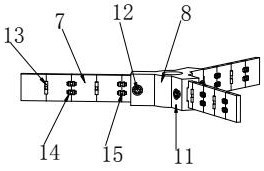

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the specific embodiments and the accompanying drawings. It should be understood that these descriptions are exemplary only and are not intended to limit the scope of the invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concepts of the present invention.

[0025] like Figure 1-4 As shown, the outer side wall of the rotating shaft 6 is connected with several connecting sleeves 8, the outer side wall of the connecting sleeve 8 is connected with three folding boxes 11, and one side of the outer side wall of the folding box 11 is connected with several stirring blades 7, and one side of the outer side wall of the stirring blade 7 is connected with There is a fixing buckle 14, and the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com