Processing technology for precisely-matched connecting holes of water pump main shaft and motor main shaft

A processing technology and motor technology, which is applied in the field of precision matching connection hole processing technology, can solve the problem that the water pump spindle and the motor spindle are not interchangeable, and achieve the effects of ensuring processing accuracy, improving installation efficiency and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

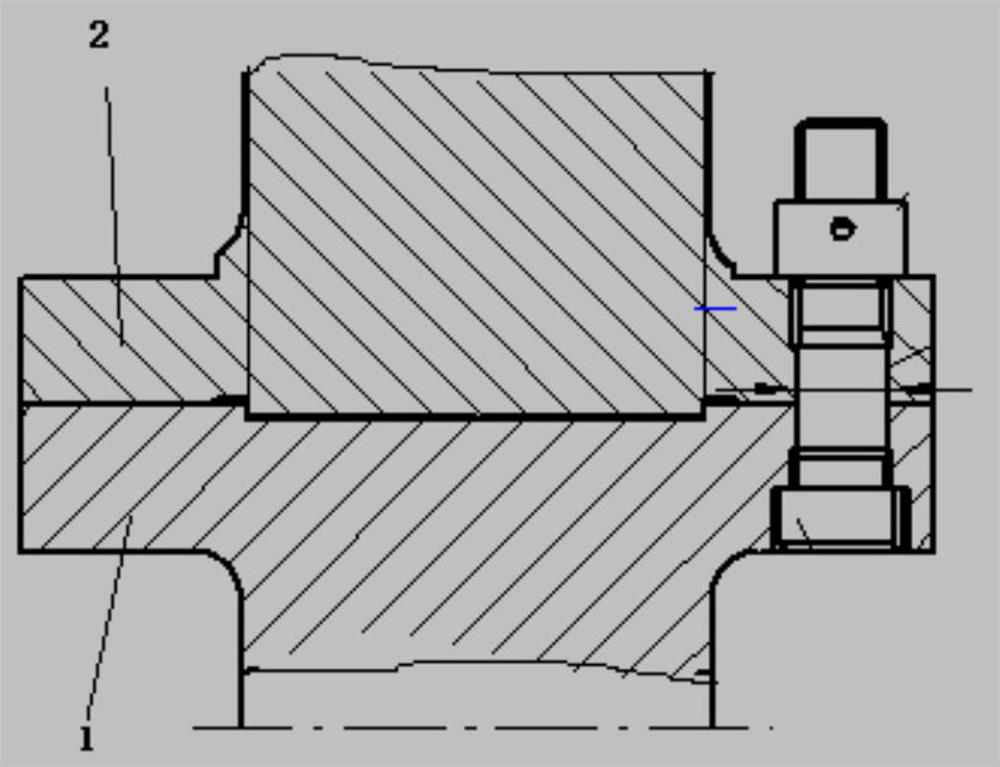

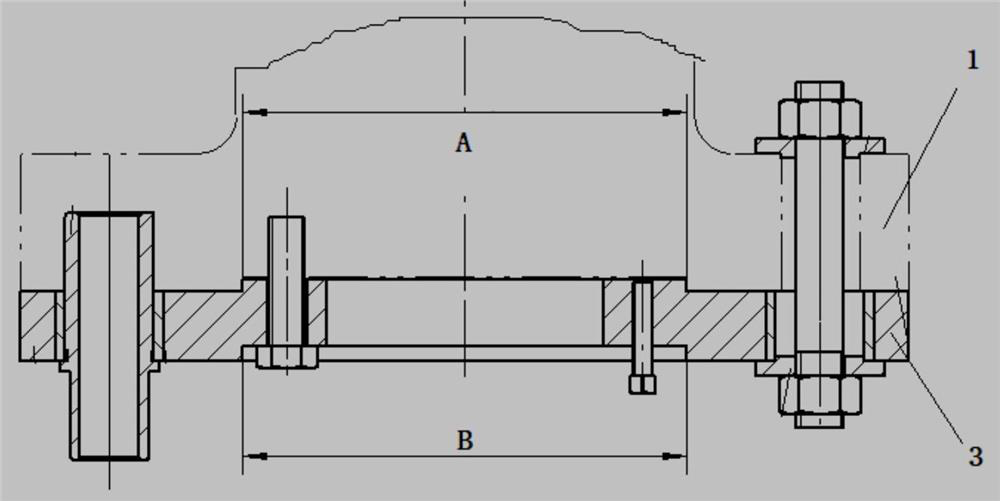

[0023] 1. If figure 1 and figure 2 As shown, for rough machining of water pump spindle 1 and motor spindle 2 on the upper horizontal car, a margin of 2mm-3mm on one side is reserved for each part, and the end faces of the two ends are turned in place;

[0024] 2. Perform ultrasonic inspection;

[0025] 3. Mark the cross line at the center of the flanges at the two ends of the pump spindle 1 and the raised flange end of the motor spindle 2, respectively, and the processing line of each connection hole;

[0026] 4. Set up the CNC boring machine, align with the line, and leave a 10mm allowance for each finely matched connecting hole, and drill and boring the remaining holes in place;

[0027] 5. Finish machining on the sleeping car: the inner circle of the concave flange stop of the water pump spindle 1, the outer circle and end face of the convex flange stop of the motor spindle 2 are processed to the drawing size; the pump spindle 1 convex flange stop, outer circle, end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com