Circular filter cloth cutting device

A filter cloth and cutting technology, which is applied in metal processing and other directions, can solve problems such as deformation and lack of fixing of filter cloth, and achieve the effect of complete cutting, convenient collection, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

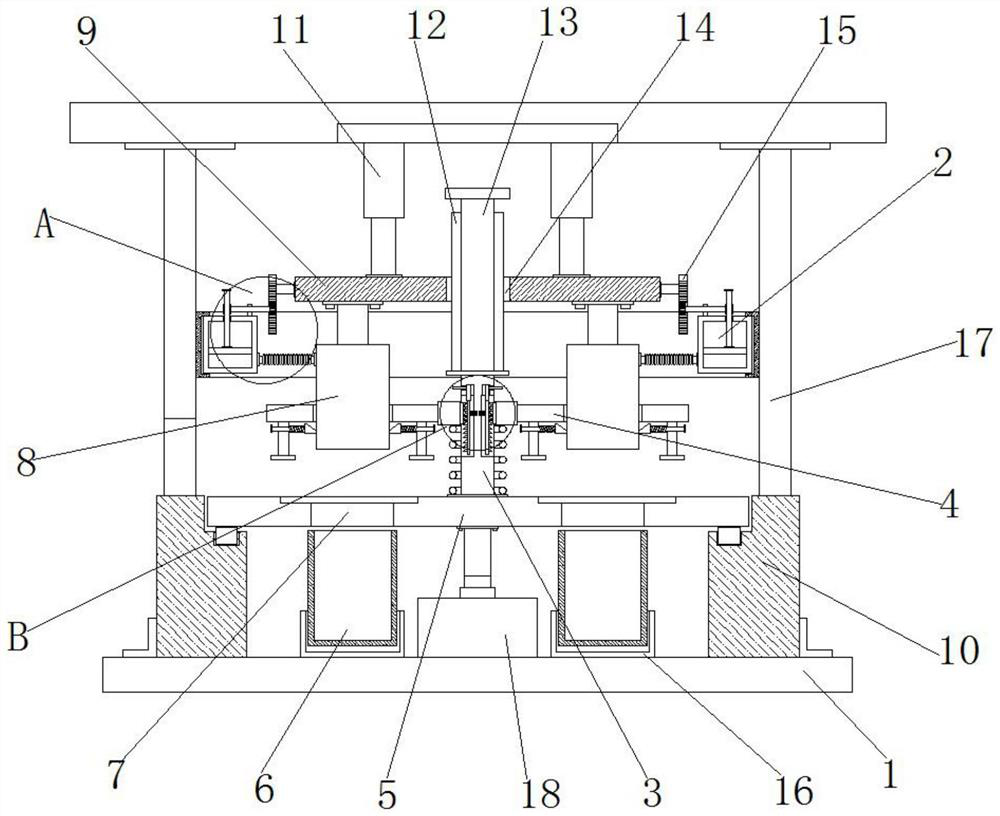

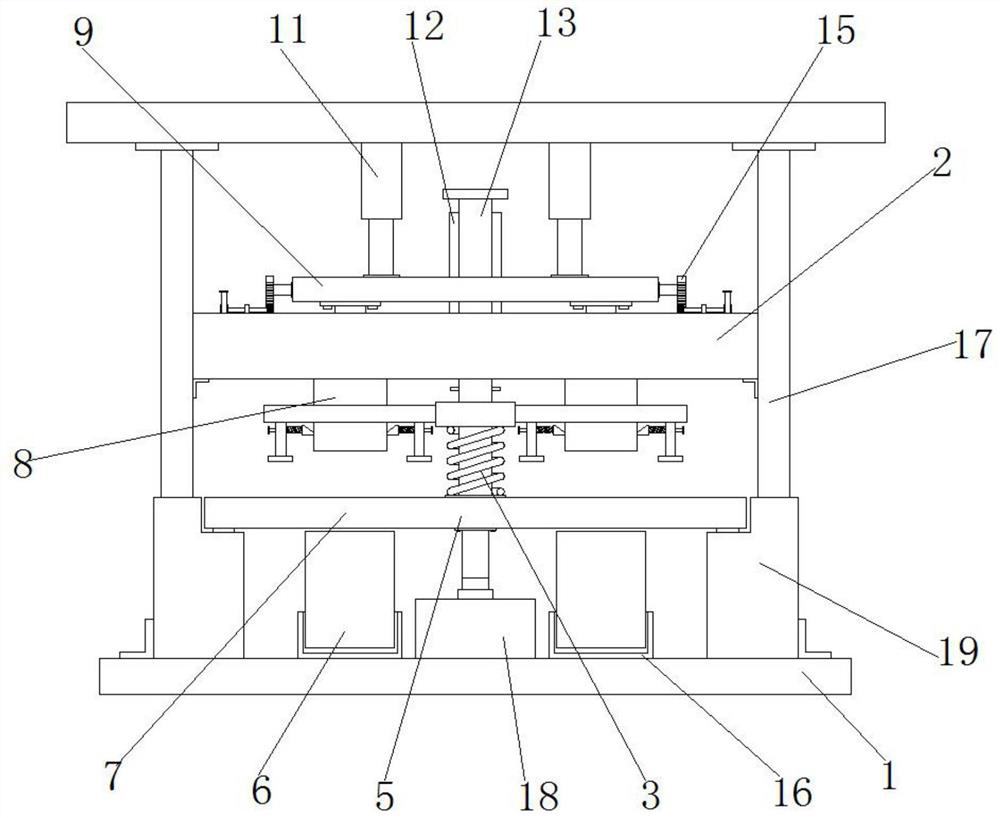

[0046] Example 1, as figure 1 , 2 As shown in , 4 and 5, the circular hollow knife 8 will gradually pass through the interior of the through groove 402 when moving. At this time, the circular hollow knife 8 will be in contact with the two groups of contact heads 403. Because the elastic force of the two groups of third springs 404 is greater than The elastic forces of the two sets of second springs 307 and the first springs 304 make the circular hollow knife 8 push the two sets of contact heads 403 together to drive the connecting plates 401 to move downward together, and the two sets of connecting plates 401 simultaneously drive the collar 303 to move downward. When moving down, the oblique edges of the first teeth 302 and the second teeth 306 slide against each other. When the squeeze rod 405 contacts the filter cloth and squeezes it to a certain extent, the connecting plate 401 cannot continue to move downward. In addition, the first locking teeth 302 and the second lockin...

Embodiment 2

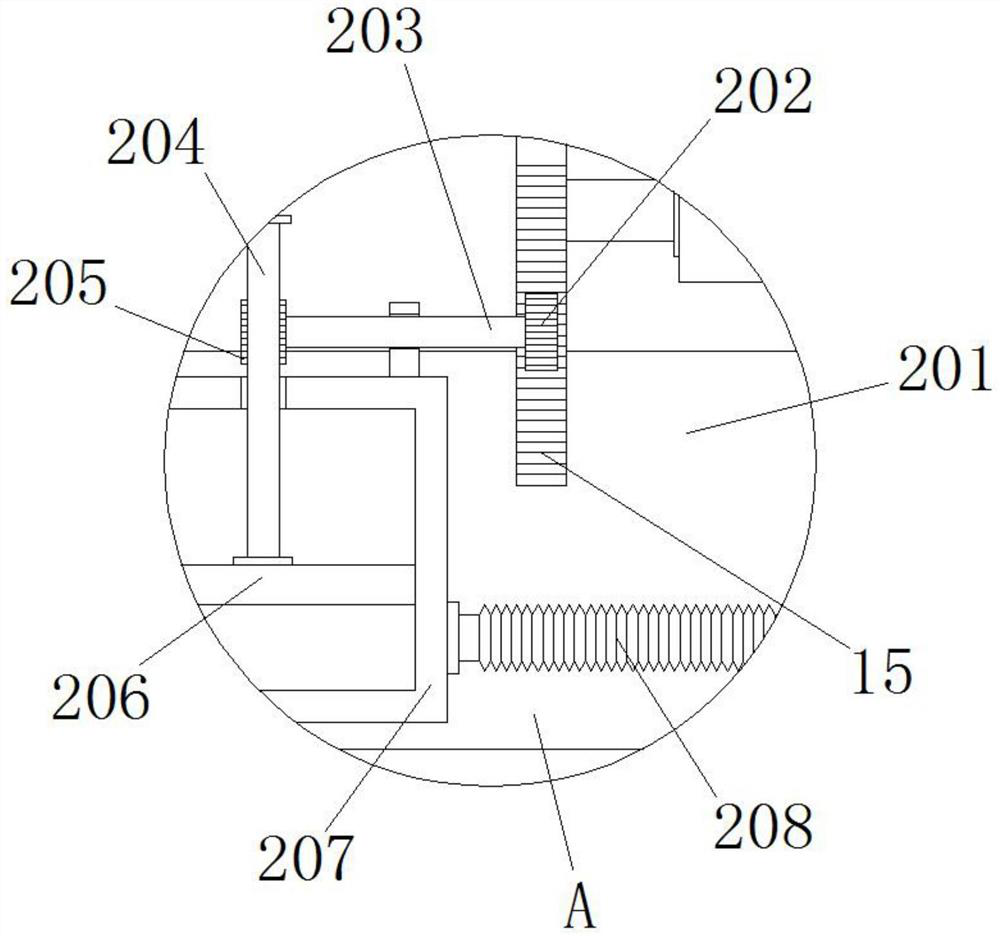

[0047] Example 2, as figure 1 , 2 As shown in and 6, when changing the cutting diameter, the rotary drive motor 18 drives the turntable 5 to rotate, and the turntable 5 drives the limit bar 12 and the slide bar 13 to rotate through the support column 301. Under the cooperation of the limit groove 14, The mounting plate 9 is driven to rotate as a whole, so as to rotate the different through holes 7 and the circular hollow knife 8 to the top of the storage box 6, so as to carry out cutting of different diameters. At the same time, the first rack 15 will rotate with the mounting plate 9, A rack 15 pushes the first gear 202 and the transmission shaft 203 to rotate, and the transmission shaft 203 pushes the entire air cavity 207 to rotate and move inside the annular slide rail 201 .

[0048] Working principle: First, place the filter cloth to be cut above the through hole 7. At this time, the electric push rod 11 drives the entire mounting plate 9 and the hollow hollow knife 8 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com