Hydrocolloid cutting mold for preventing nasal obstruction and pressure sores in neonatology department

A neonatology, hydrocolloid technology, applied in metal processing and other directions, can solve the problems of uneven size, no special equipment for drilling, and low efficiency, so as to achieve the effect of clean surface, improve work efficiency, and ensure cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

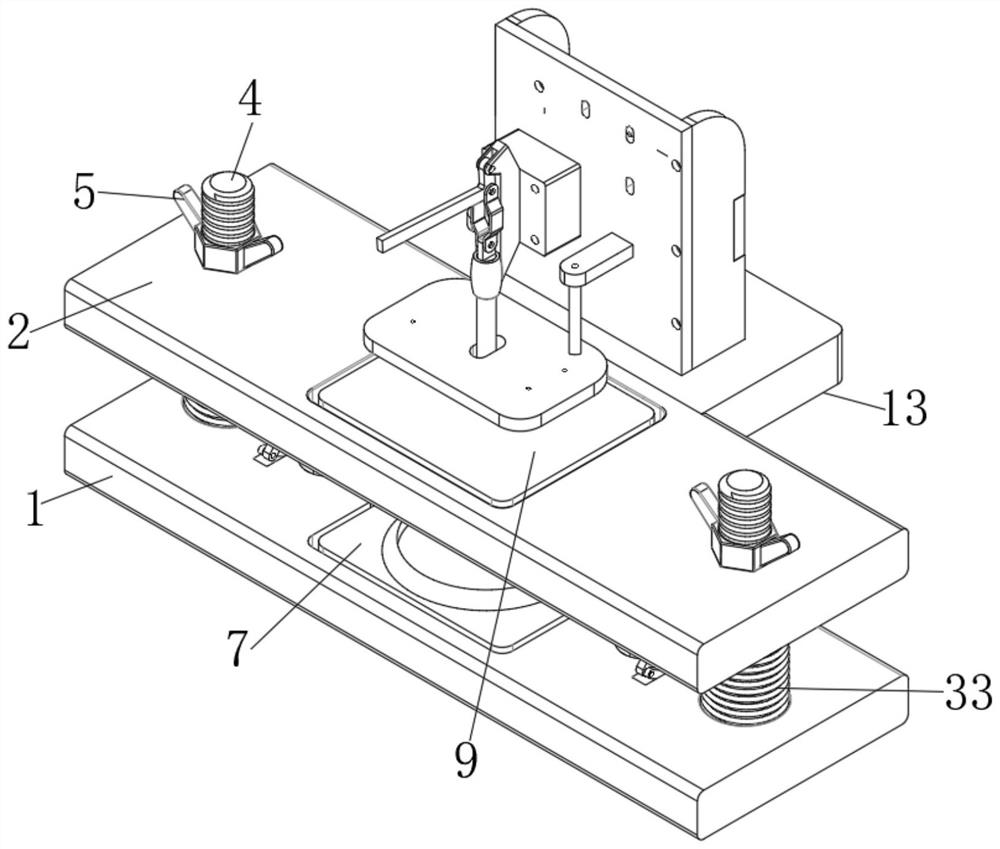

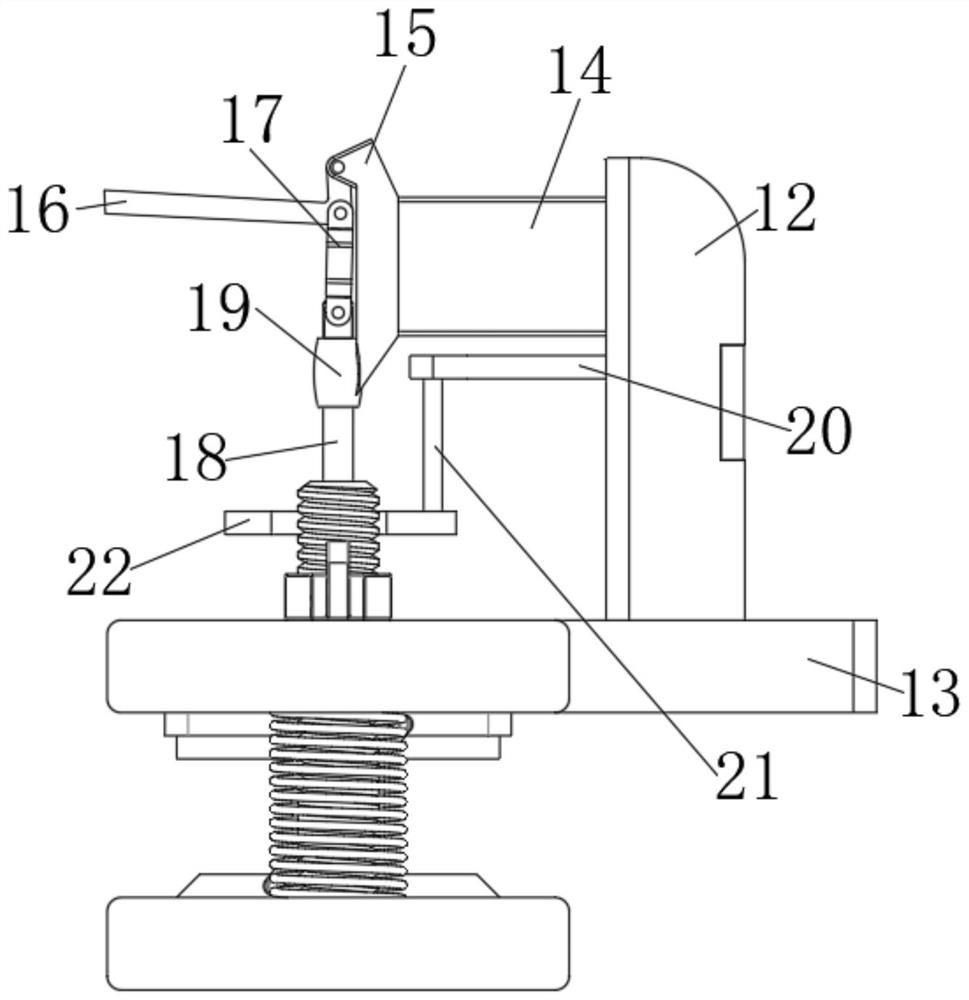

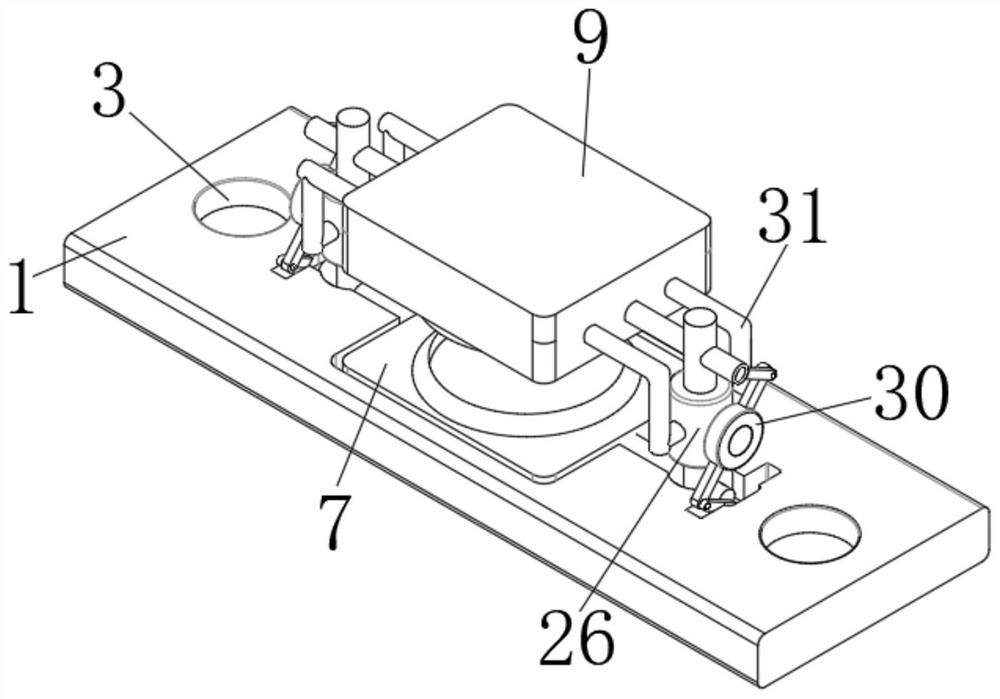

[0027] refer to Figure 1-9 , a hydrocolloid cutting mold for preventing nasal congestion and pressure ulcers in neonatology, comprising a lower template 1 and an upper template 2, first grooves 3 are symmetrically arranged on the upper ends of both sides of the lower mold 7, and the inner walls of the two first grooves 3 are fixedly connected Threaded rod 4, the two threaded rods 4 all penetrate the side wall of the upper template 2, the two threaded rods 4 are slidably connected with the penetration of the side wall of the upper template 2, the two threaded rods 4 are provided with matching nuts 5, and the two threaded rods 4. The side w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap