Moving device with buffering effect for double-sided battery production

A technology of double-sided batteries and mobile devices, which can be used in motor vehicles, transportation and packaging, trolley accessories, etc., and can solve problems such as damage to double-sided batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

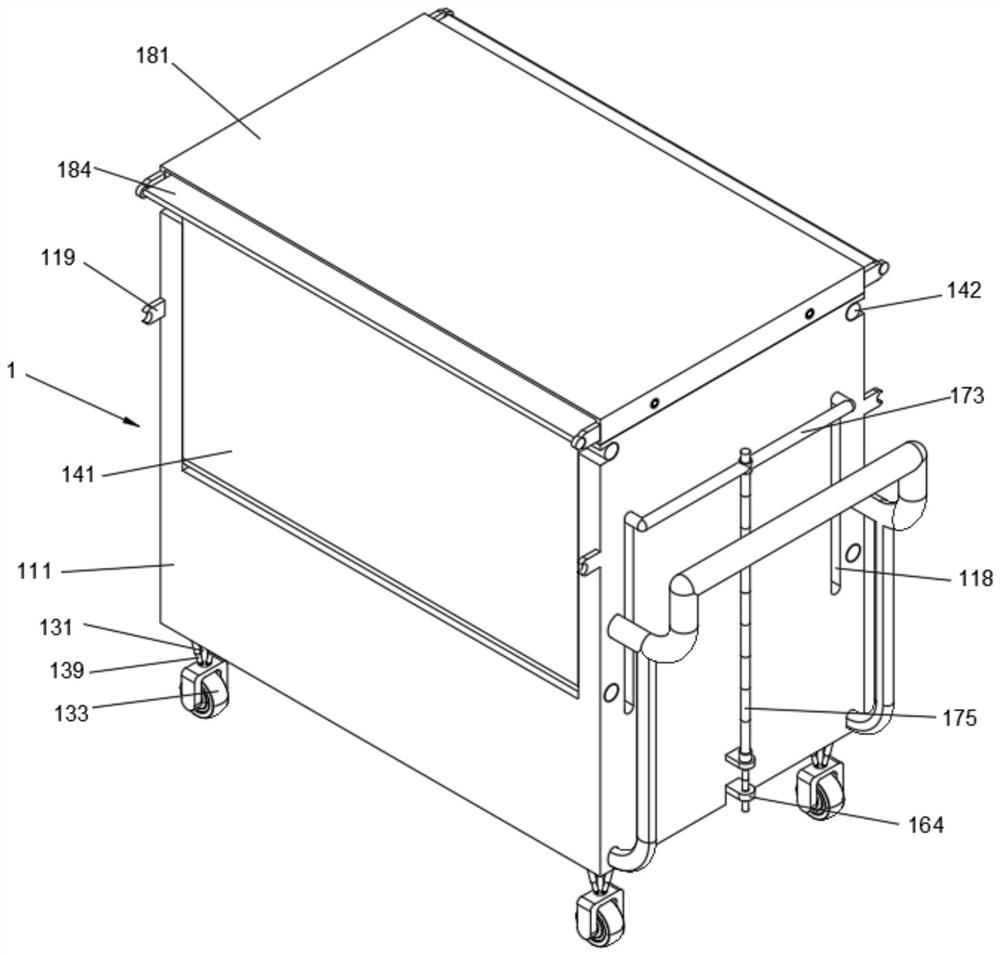

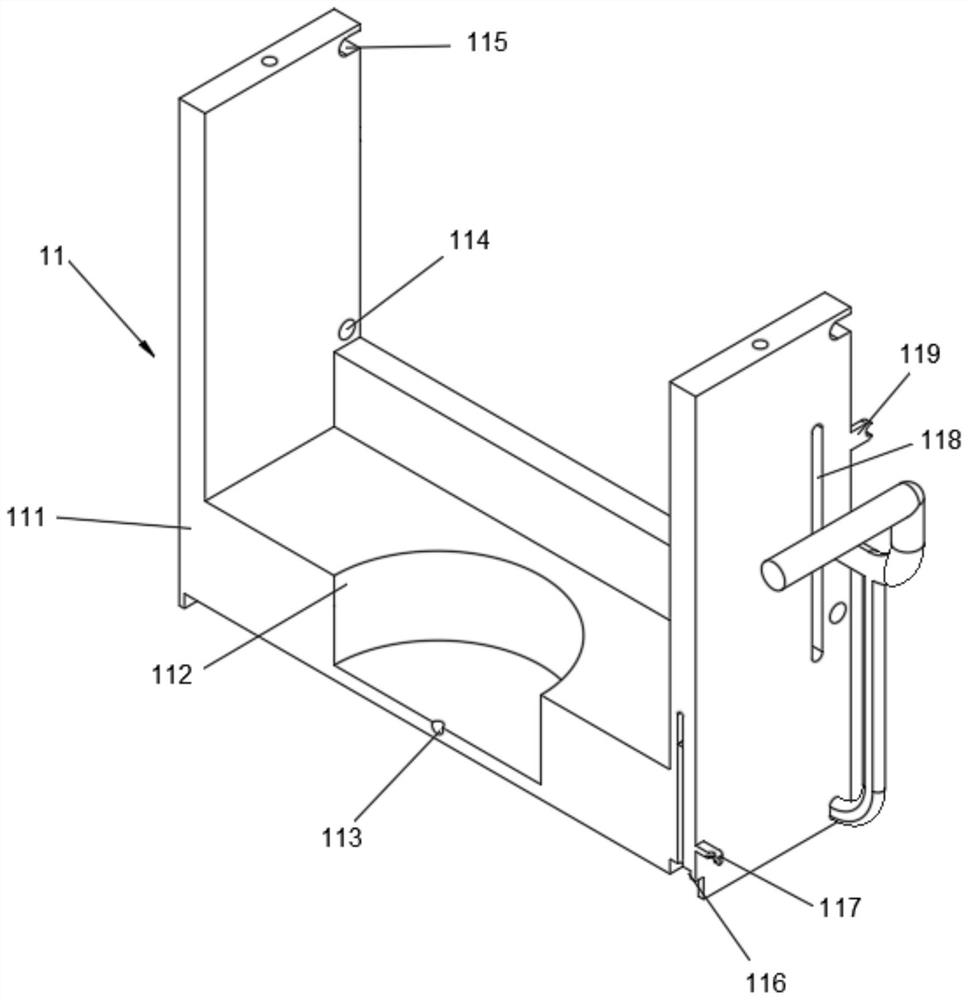

[0044] see Figure 1-Figure 8 As shown, the purpose of this embodiment is to provide a mobile device for producing a double-sided battery with a buffering effect, including a transportation device 1, and the transportation device 1 at least includes:

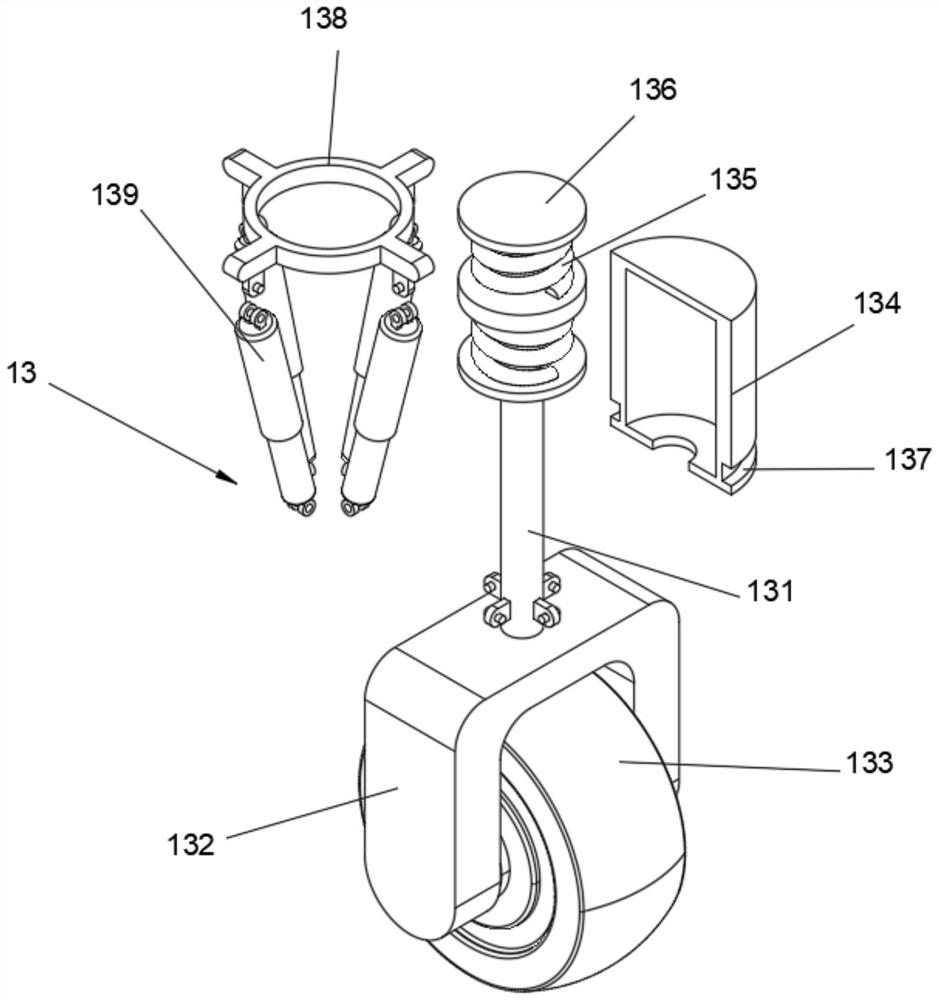

[0045]The carrier 11, the carrier 11 includes a carrier plate 111, the carrier plate 111 is a "U"-shaped structural plate, and the four corners of the bottom of the carrier plate 111 are provided with a movable body 13, and the movable body 13 includes a bearing shaft 131. The bearing shaft 131 is a "T"-shaped cylinder The bottom of the bearing shaft 131 is connected with a bottom plate 132, the bottom plate 132 is a "U"-shaped structure, the bottom ends of the bottom plate 132 are rotatably connected with rollers 133, the top of the bearing shaft 131 is located in the top sleeve 134, and the top sleeve 134 has a " A cylinder with a T"-shaped cylindrical structure groove, the top of the top sleeve 134 is connected to the bottom ...

Embodiment 2

[0053] see Figure 9 As shown, in order to avoid accidental loss of double-sided cells during transportation, this embodiment makes the following improvements on the basis of Embodiment 1:

[0054] Among them, in order to control the retraction of the frame 161, the frame 161 is inserted and matched with the side groove 116, and an outer plate 164 is connected to one side of the frame 161. The outer plate 164 is a square plate with a circular opening. 164 passes through the surface of the carrier plate 111. The outer surface of the carrier plate 111 close to the frame 161 is provided with a side plate 117. The locking body 17, the locking body 17 includes a bottom screw 171, the bottom screw 171 is rotatably connected to the side plate 117, the bottom of the bottom screw 171 passes through the outer plate 164, and the bottom screw 171 is threadedly connected to the outer plate 164. Rotating the bottom screw 171 in the side plate 117 can drive the outer plate 164 threadedly co...

Embodiment 3

[0059] see Figure 10 As shown, in order to ensure the cleanliness of the double-sided battery during transportation, this embodiment makes the following improvements on the basis of Embodiment 1:

[0060] Among them, since the double-sided battery needs to be kept clean when the double-sided battery is transported, a shielding body 18 is provided on the top of the carrier plate 111 , and the shielding body 18 includes a shielding plate 181 whose bottom ends are inserted and matched with the top two ends of the supporting plate 111 . 181 is a square plate with square grooves on both sides, a shaft groove 182 is formed in the shutter 181, the shaft groove 182 is a circular through hole, the shaft groove 182 is rotatably connected with an inner shaft 183, and the surface of the inner shaft 183 is covered with a cover. Cloth 184, the other end of the cover cloth 184 is connected with the outer shaft 185. By providing the shielding body 18, the outer shaft 185 is grasped and pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com