Automatic raw material elevator for non-ferrous metal calendering processing

A technology of rolling processing and non-ferrous metals, which is applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of workers falling from heights and large safety hazards, so as to improve output efficiency and reduce the probability of spilling , The effect of reducing the probability of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

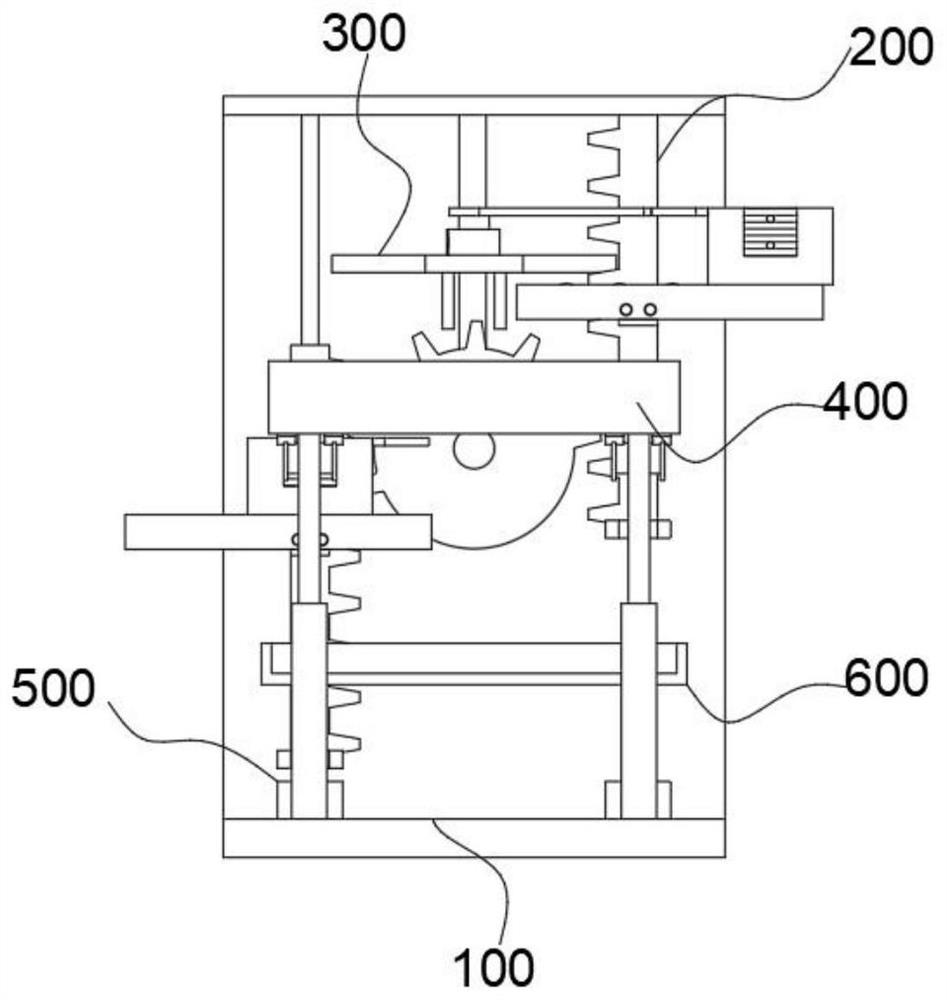

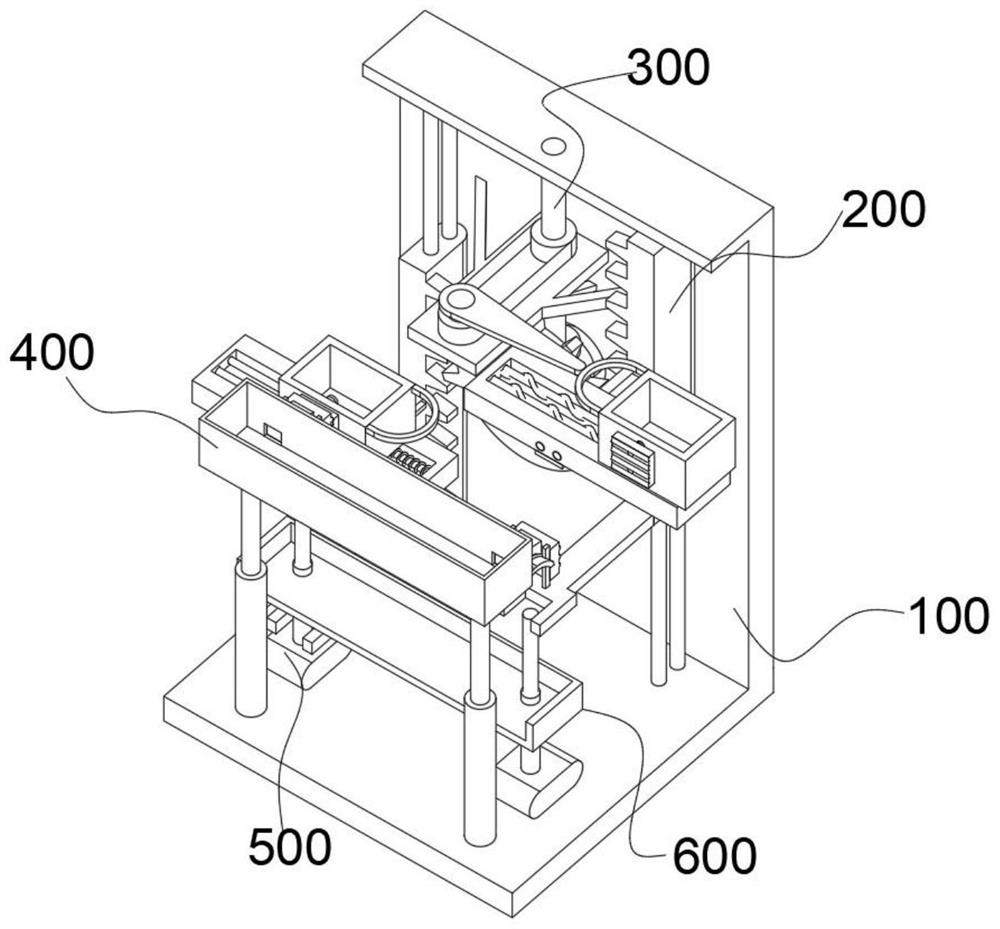

[0045] combine Figure 1-8 As shown, the present invention provides an automatic hoist for raw materials for non-ferrous metal calendering processing, including a frame 100, and the frame 100 is provided with a feeding module 200, a pushing module 300, a discharging module 400 and a control module 500, The feeding module 200 includes a motor 210 installed on the rear side of the rack 100 , an incomplete gear 220 located on the front side of the rack 100 and connected to the output shaft of the motor 210 , and the incomplete gear 220 Two toothed plates 230 that are symmetrical and meshed with the incomplete gears 220 , a plurality of guide rods 240 that slide through the two toothed plates 230 and are connected to the frame 100 , are installed in front of the toothed plates 230 The supporting plate 250 on the side, the material frame 260 slidably installed on the top of the supporting plate 250 , and the two round rods 270 embedded in the top of the supporting plate 250 and sli...

Embodiment 2

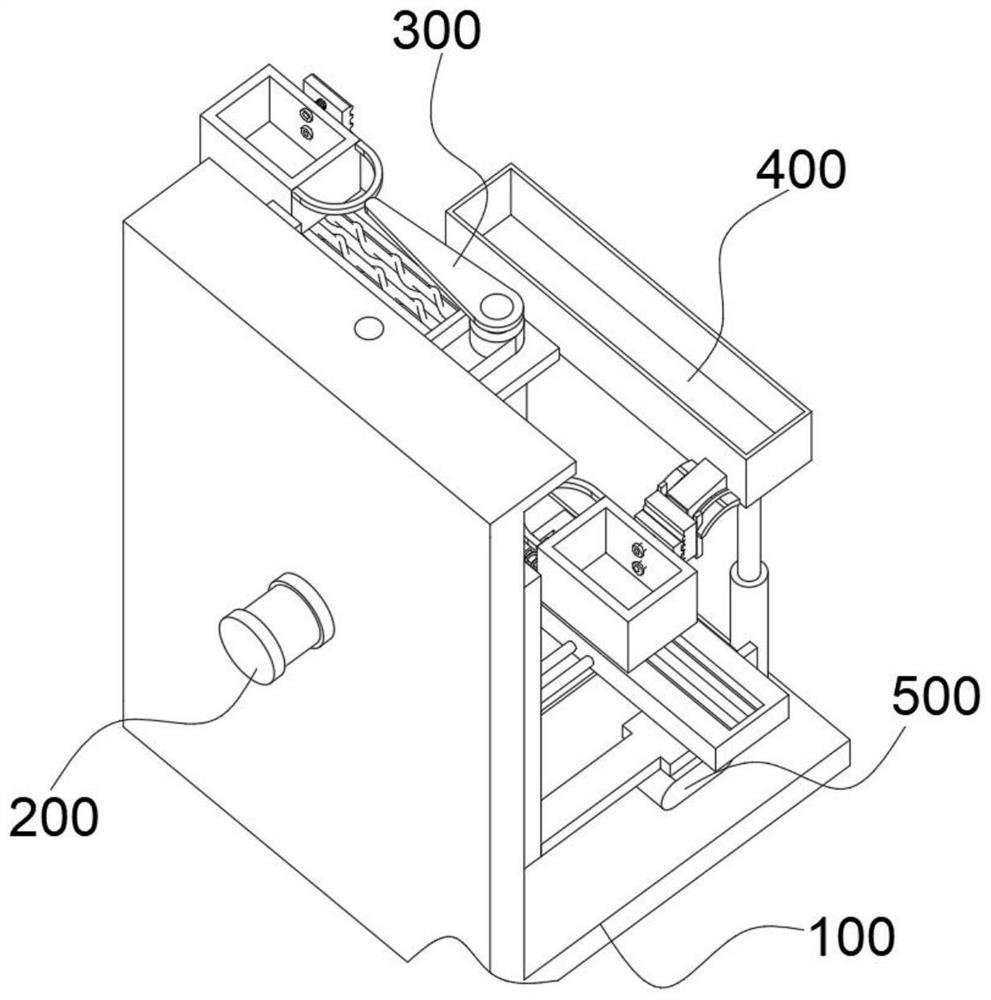

[0054] combine Image 6 As shown, on the basis of Embodiment 1, there is a gap between the rear side of the incomplete gear 220 and the front side of the frame 100, the first bevel gear 330 and the second bevel gear 340 are located inside the gap, and the gap Provide installation space for the first bevel gear 330 and the second bevel gear 340 to ensure that the first shaft 320 can rotate smoothly, thereby indirectly rotating the second shaft 350 and the push rod 380 to ensure that the material frame 260 can be moved to a safe position.

Embodiment 3

[0056] combine Figure 1-3 As shown, in the above-mentioned embodiment, the top of the frame 100 is provided with a material receiving box 600, the material receiving box 600 is sleeved on the outside of the two hollow cylinders 520, and the material receiving box 600 is used for receiving self-discharging materials The raw materials dropped on the channel 430 can avoid waste of raw materials.

[0057] The working principle and use process of the present invention: after filling the raw material box 420 with raw materials, the device is put into practical use, firstly, the motor 210 connected with the incomplete gear 220 and the second bevel gear 340 is started, and then the incomplete gear 220 drives the The material frame 260 on the right side with the raw material is raised, and then the empty material frame 260 on the left side is lowered. When the left side material frame 260 is lowered, the second clamping plate 470 on the front side is connected to the first clamping pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com