Converter valve power module replacing device

A power module and converter valve technology, applied in the field of converter valve power module replacement device, can solve the problems of cumbersome replacement methods, low replacement efficiency, time-consuming and labor-consuming, etc., to improve safety and convenience, and improve replacement efficiency , The effect of saving tooling positioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

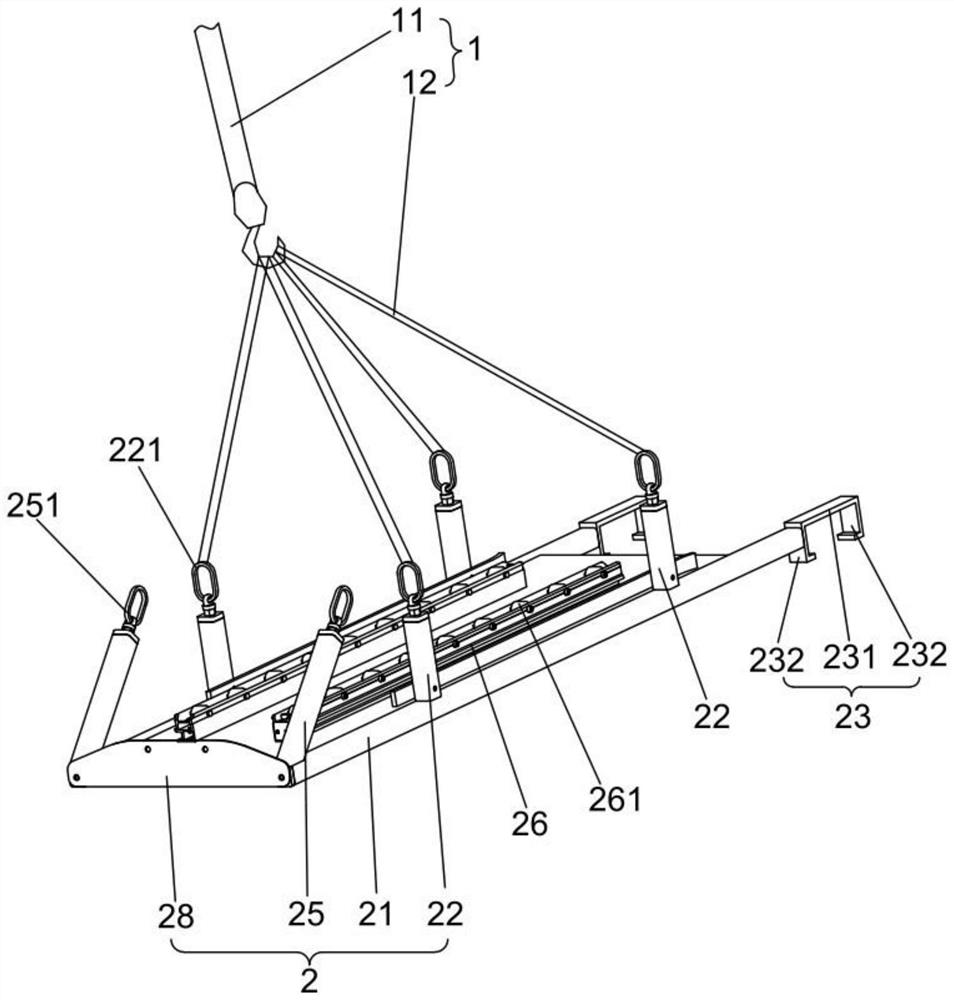

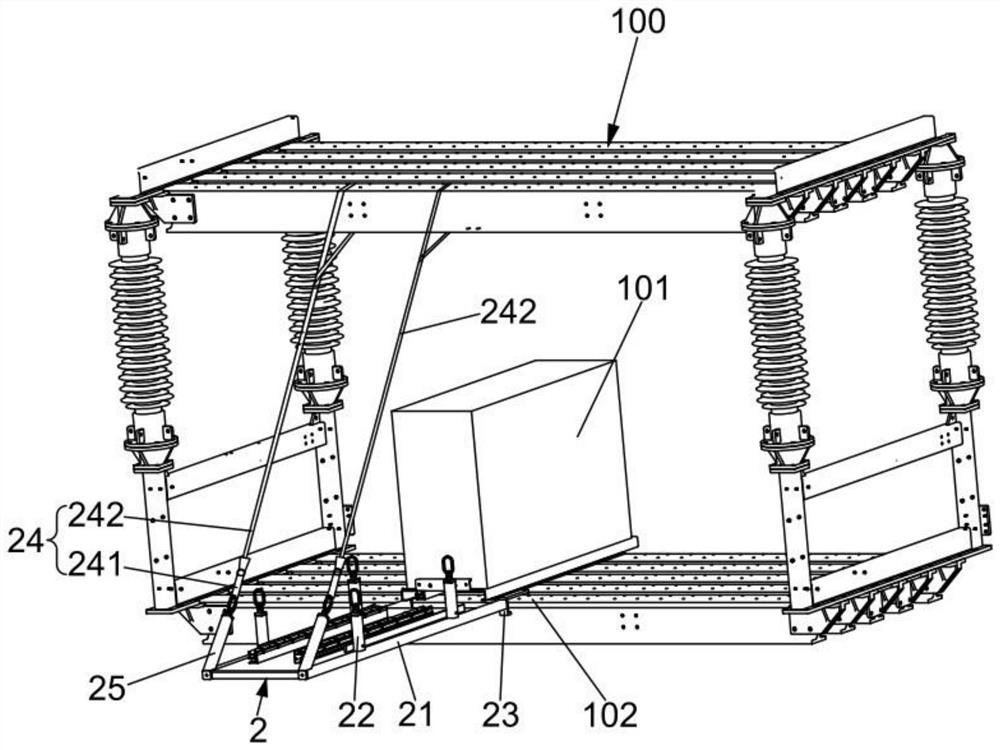

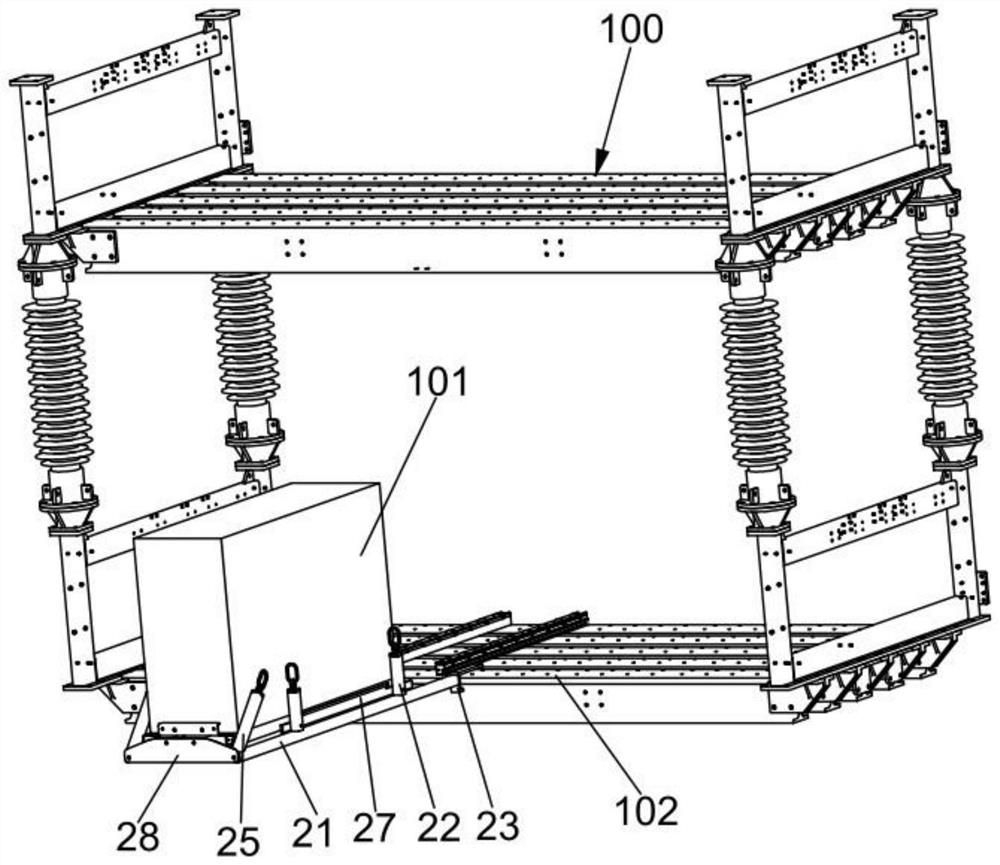

[0037] The rapid maintenance and replacement of the converter valve power module of the DC distribution network is an important part of the maintenance and repair of the converter valve. This embodiment provides a converter valve power module replacement device, which can realize the rapid replacement of the converter valve power module and improve the The replacement speed and replacement efficiency of power modules are improved, and the safety of power module replacement is improved. Specifically, as figure 1 As shown, the converter valve power module replacement device includes a hoisting module 1 and a refueling module 2. The hoisting module 1 can hoist the refueling module 2 to the installation position of the converter valve power module 101 to be replaced, so that the refueling module 2, the converter valve power module 101 is replaced, which saves the tooling positioning time and improves the replacement efficiency.

[0038]The refueling module 2 includes a support pl...

Embodiment 2

[0060] This embodiment provides a converter valve power module replacement device, which is basically the same as the converter valve power module replacement device provided in the first embodiment. The difference between this embodiment and the first embodiment is that in this embodiment, the suspension The length of the hanger 25 is adjustable. Specifically, the suspension frame 25 is formed by a plurality of hollow telescopic rods that are sleeved together. By sequentially pulling two adjacent telescopic rods, the length of the suspension frame 25 can be extended to adjust the length of the suspension frame 25, which is supported by the suspension member 24, The length of the hypotenuse of the triangle formed by the platform 21 and the valve tower 100 enables the support platform 21 to remain horizontal. Wherein, one of the two adjacent telescopic rods is provided with at least two first engaging portions at intervals along its axial direction, and the other is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com