Liftable tower crane and lifting regulation and control method thereof

A tower crane and lift-type technology, applied in cranes and other directions, can solve the problems of convenience and inconvenience of increasing the working difficulty of tower cranes, and achieve the effect of increasing working difficulty and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

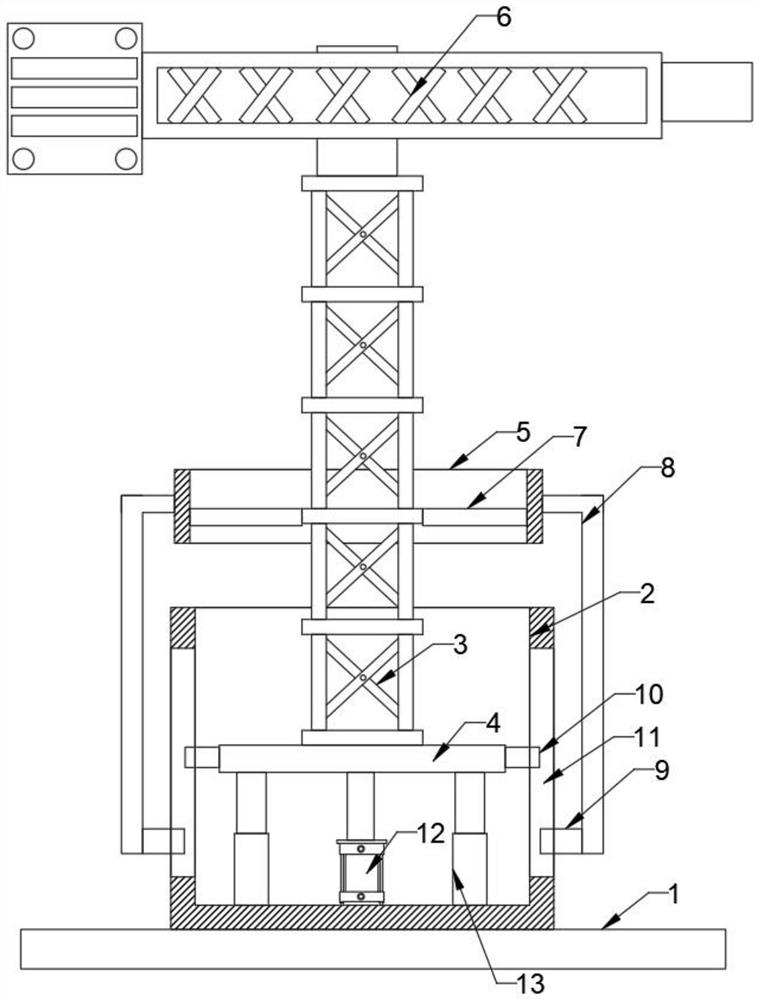

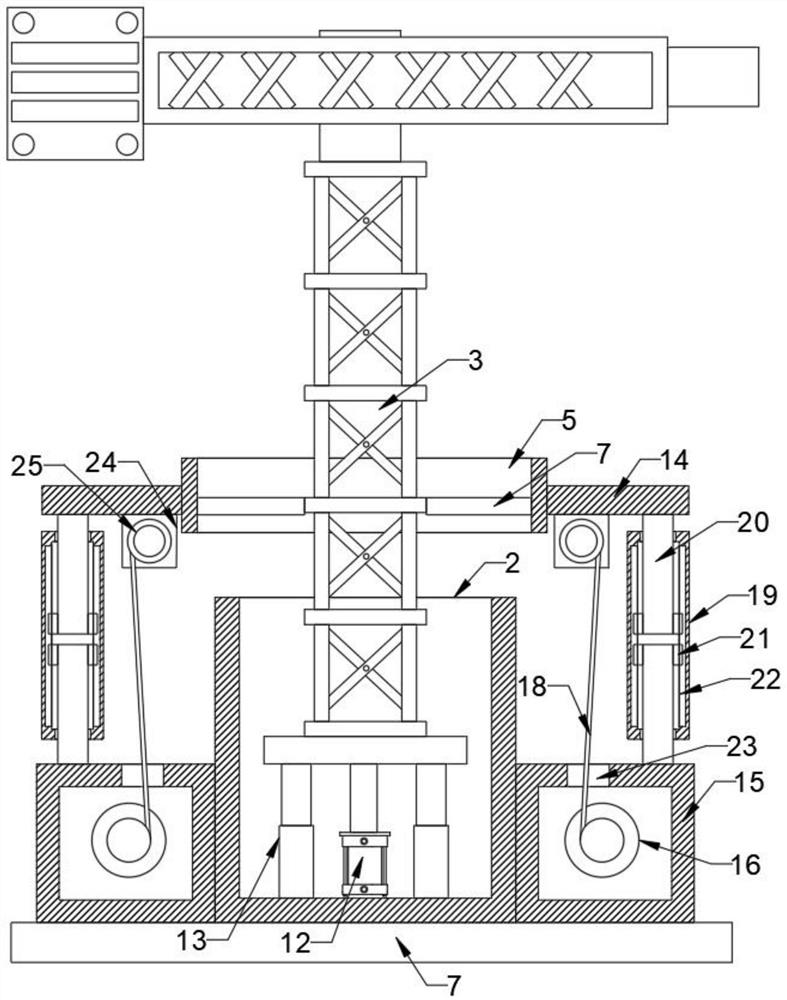

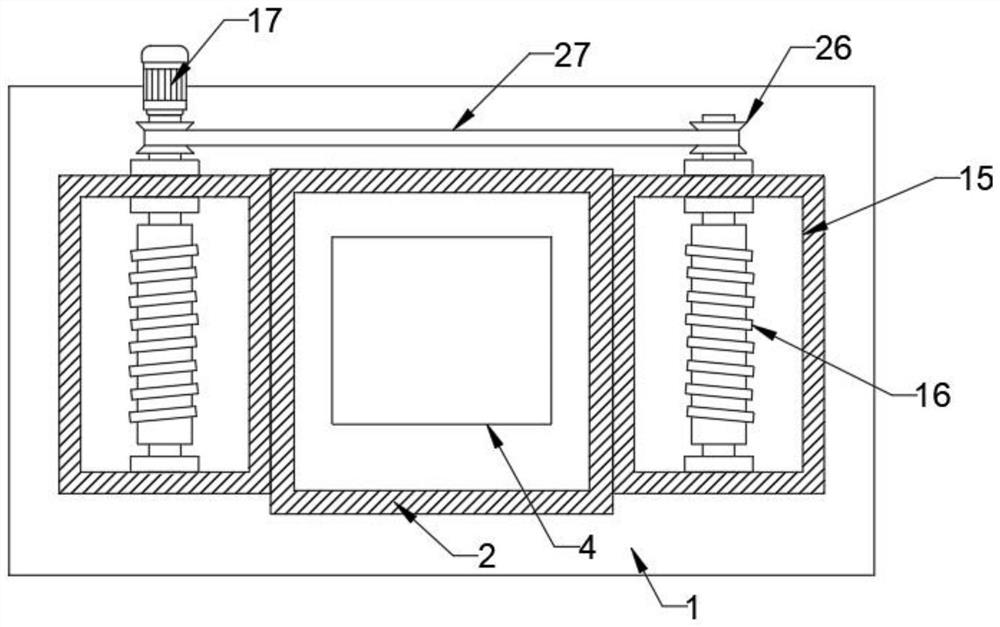

[0025] refer to Figure 1-4 , including the base 1, the bottom of the base 1 is fixedly connected with a bearing frame 2, and the inner side of the bearing frame 2 is slidably connected with a bearing plate 4, the top of the bearing plate 4 is installed with a tower body 3, and the top of the tower body 3 is installed with a lifting Arm 6, the inner bottom of the bearing frame 2 is fixedly connected with a large hydraulic cylinder 12 by bolts, and the output end of the large hydraulic cylinder 12 is fixedly connected with the bottom of the bearing plate 4, and the middle of the tower body 3 is sleeved with a top frame 5, And the inner wall of the top frame 5 is fixedly connected with the tower body 3 through the connecting plate 7, both sides of the bearing frame 2 are fixedly connected with the bottom frame 15, and one side of the two bottom frames 15 is fixedly connected with a bolt. The driving motor 17, the inner sides of the two bottom frames 15 are rotatably connected wi...

Embodiment 2

[0028] refer to Figure 1-4 , between the two side plates 14 and the tops of the two bottom frames 15 are respectively provided with a bearing tube 19, and the inner upper part and the inner lower part of the bearing tube 19 are slidably connected with inner rods 20, and the two inner rods 20 are away from each other. One end of the two inner rods 20 is fixedly connected to the bottom of the side plate 14 and the top of the bottom frame 15 respectively, and one end of the four inner rods 20 is connected to the two carrying pipes 19 respectively. The poles are all sliding connections, the two sides of the four inner rods 20 are fixedly connected with sliding blocks 21, and the sliding blocks 21 are slidably connected with the inner wall of the bearing tube 19 through the sliding groove 22;

[0029] The inner rod 20 is used to slide in the carrier tube 19 , thereby further improving the stability of the tower body 3 as a whole during lifting and lowering.

Embodiment 3

[0031] refer to Figure 1-4 , the lifting control method includes the following steps:

[0032] S1: Start the large hydraulic cylinder 12 to drive the bearing plate 4 to move up and down in the bearing frame 2, so that the tower body 3 can be adjusted up and down;

[0033] S2: At the same time, when the tower body 3 moves up and down, the driving motor is started to drive the winding rod 16 to rotate, so that the tower body 3 can be moved up and down while maintaining the stability of the tower body 3 through the steel cable 18;

[0034] S3: When the tower body 3 moves up and down, the two inner rods 20 inside the carrying tube 19 will expand and contract, and the stability of the tower body 3 can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com