Novel lifting equipment for inspecting water-cooled wall tube in boiler

A technology for water-cooled wall pipes and lifting equipment, which is applied in the direction of lifting equipment safety devices, lifting devices, etc., can solve the problems of affecting the heating safety of the unit, low work efficiency, safety accidents, etc., to avoid safety accidents, easy to use, and easy to operate. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

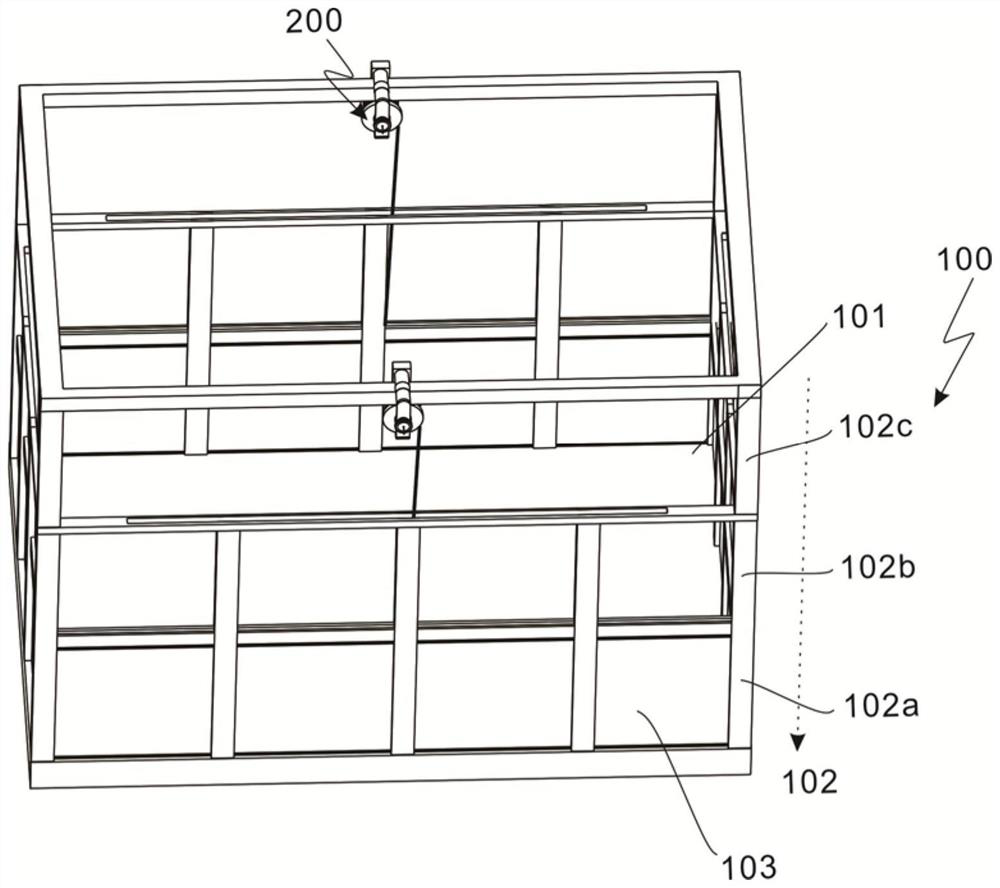

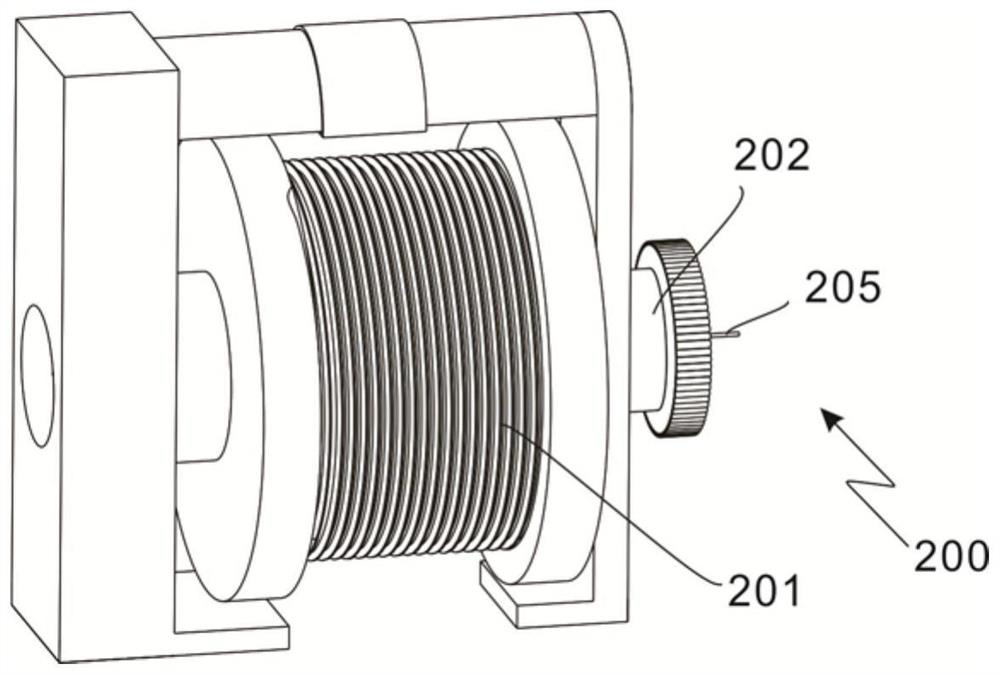

[0031] refer to Figure 1 to Figure 3 , which is the first embodiment of the present invention, which provides a new type of lifting equipment for inspecting water-cooled wall tubes inside a boiler, including a lifting assembly 100 and a rotating assembly 200. The lifting assembly 100 includes a lifting platform 101, a grid guardrail 102 and a lifting device The plate 103, the grid guardrail 102 is fixed on the top of the lifting platform 101, the lifting plate 103 is arranged in the grid guardrail 102; the rotating assembly 200, the rotating wheel 201 and the rotating member 202, the rotating member 202 is fixed on the top of the grid guardrail 102, the rotating member 202 passes through the rotating wheel 201.

[0032] Preferably, the grid guardrail 102 is lighter in quality than the guardrails that are fully enclosed around it. The use of the lift plate 103 can solve the problem that the maintenance tool has fallen from the periphery of the lift table 101; the addition of t...

Embodiment 2

[0036] refer to Figure 1 to Figure 6 , is the second embodiment of the present invention, which is different from the previous embodiment in that: the grid guardrail 102 includes a first column 102a, a second column 102b and a third column 102c, and the first column 102a is fixed on the lifting platform At the top of 101, the first column 102a and the third column 102c are connected by the second column 102b.

[0037] The lift plate 103 reciprocates between the first column 102a and the second column 102b.

[0038] Preferably, the rotating assembly 200 is arranged on the top of the first column 102c, and the rotating member 202 can be rotated, so that the rotating wheel 201 can retract and pay off the pull rope, and drive the lifting plate to rise or fall, and the lifting plate 103 is pulled by the pull rope. Back and forth between the first column 102a and the second column 102b.

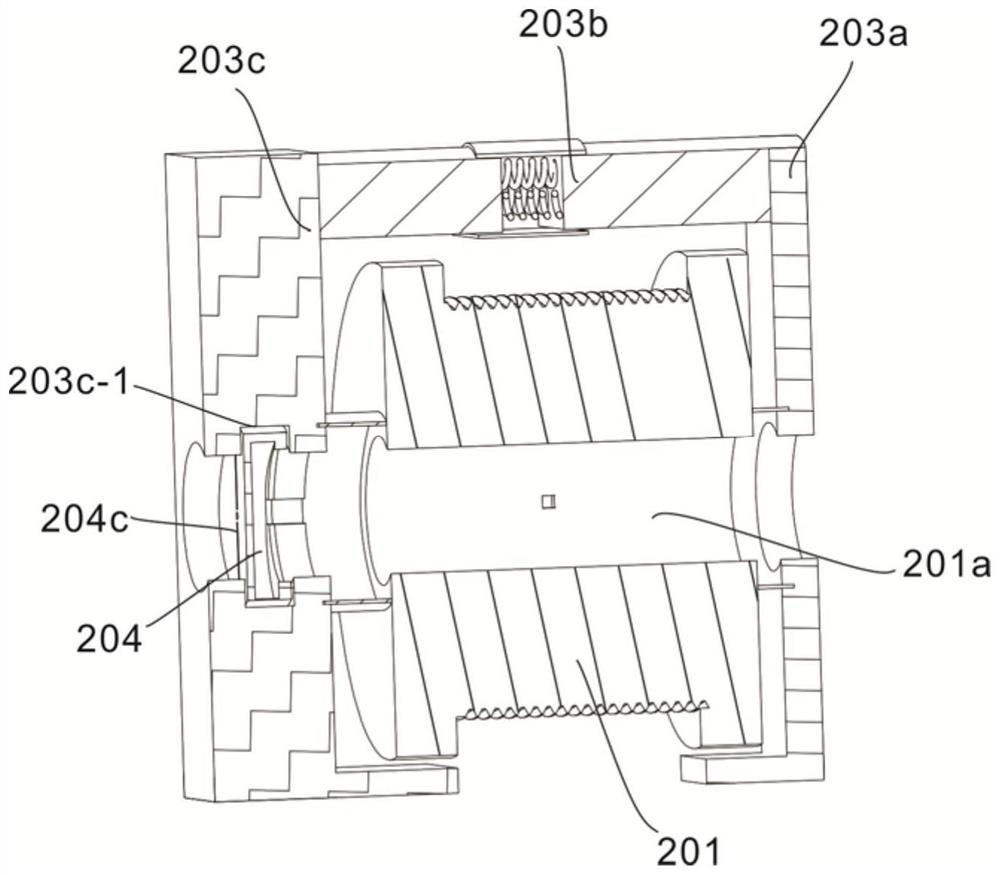

[0039] A connecting member 203 is provided on the outside of the rotating wheel 201. The con...

Embodiment 3

[0047] refer to Figure 1 to Figure 9 , is the third embodiment of the present invention, which is different from the previous two embodiments in that the telescopic member 205 passes through the rotating member 202 and the rotating disk 204 .

[0048] Preferably, the telescopic member 205 passes through the rotating member 202 and the rotating disk 204 first, and locks and unlocks the rotating disk 204 .

[0049] The telescopic member 205 includes a moving rod 205a, a connecting sleeve 205b and a push rod 205c. The moving rod 205a passes through the rotating member 202 and the rotating disk 204. The connecting sleeve 205b is fixedly arranged on the other side of the rotating disk 204, and the sliding groove 204c is opened at the The other side of the rotating disk 204, one side of the sliding block 204d is arranged in the sliding groove 204c, and one end of the push rod 205c is rotatably connected with the moving rod 205a.

[0050] Further, the connecting sleeve 205b is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com