Steel structure formwork for building

A technology for steel structure and construction, applied in the direction of building structure, construction, construction components on-site preparation, etc., can solve the problems of poor splicing stability of steel structure formwork, poor splicing support force, low efficiency of bolt combination splicing, etc., to achieve Easy splicing and separation, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

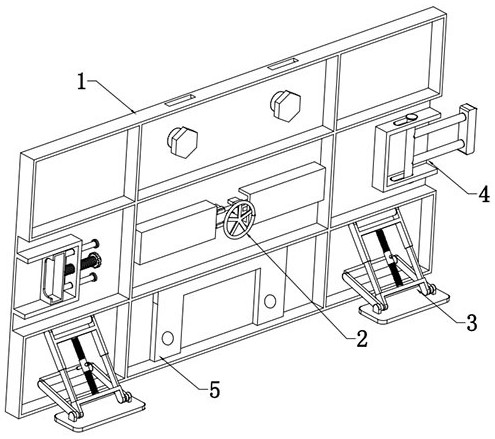

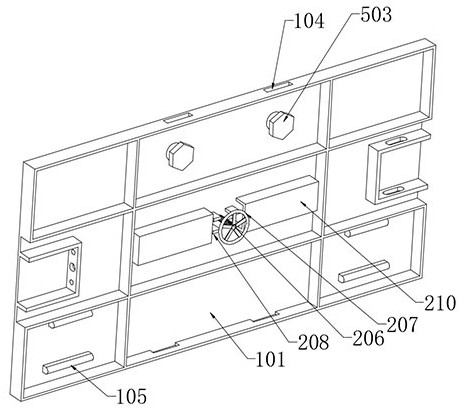

[0035] like Figure 1 to Figure 11 As shown, a steel structure formwork for construction includes a formwork body 1, a separation component 2, a support component 3, a horizontal connection component 4 and a vertical connection component 5. The middle of the formwork body 1 is provided with a separation component 2. Two symmetrically distributed support assemblies 3 are arranged at the bottom end of the side surface, horizontal connection assemblies 4 are arranged on both sides of the outer side of the formwork body 1, and vertical connection assemblies 5 are arranged in the middle of both ends of the outer side of the formwork body 1;

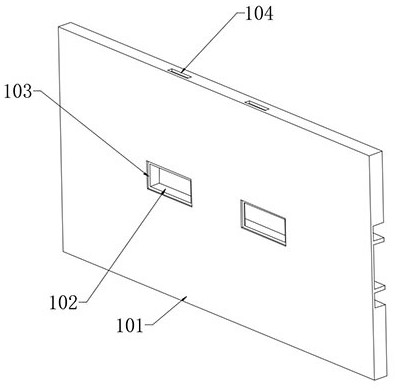

[0036] Formwork body 1. Formwork body 1 includes a fixing plate 101. Two symmetrically distributed square grooves 102 are formed through the middle of the inner side of the fixing plate 101. A groove 103 is formed at the notch of the square groove 102. Two symmetrically distributed slots 104 are provided through the fixing plate 101 , and two ...

no. 2 example

[0049] like Figure 12 As shown in the figure, after the device is spliced and concrete is poured between the steel structure formwork, there will be a large amount of gas inside the concrete. If the gas cannot be discharged in time, cracks will appear in the solidified concrete, and the concrete will During the solidification process, its volume will shrink. If the steel structure formwork cannot adjust its gap correspondingly with the change of the concrete volume, it will cause cracks in the solidified concrete and reduce the strength and aesthetics of the concrete structure. The exhaust effect and the adaptive adjustment effect when the concrete is poured and solidified, the steel structure formwork for building also includes: the outer surface of the push plate 203 is provided with a pressure sensor, and the pressure of the concrete on the outer surface of the push plate 203 can be effectively detected by means of the sensor. value.

[0050] The inner bottom of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com