Single-screw pump

A single-screw pump and pump casing technology, applied to pumps, pump components, rotary piston pumps, etc., can solve the problems of difficult rotor installation and troublesome rotor disassembly, reduce the possibility of low transmission efficiency, facilitate disassembly and assembly, The effect of quick installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

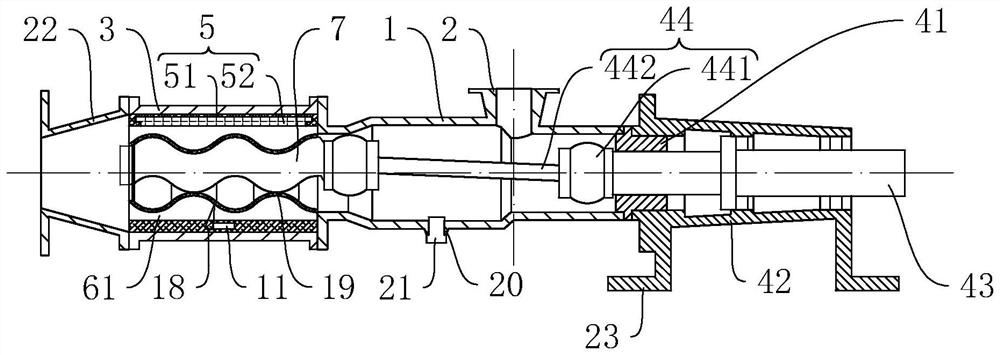

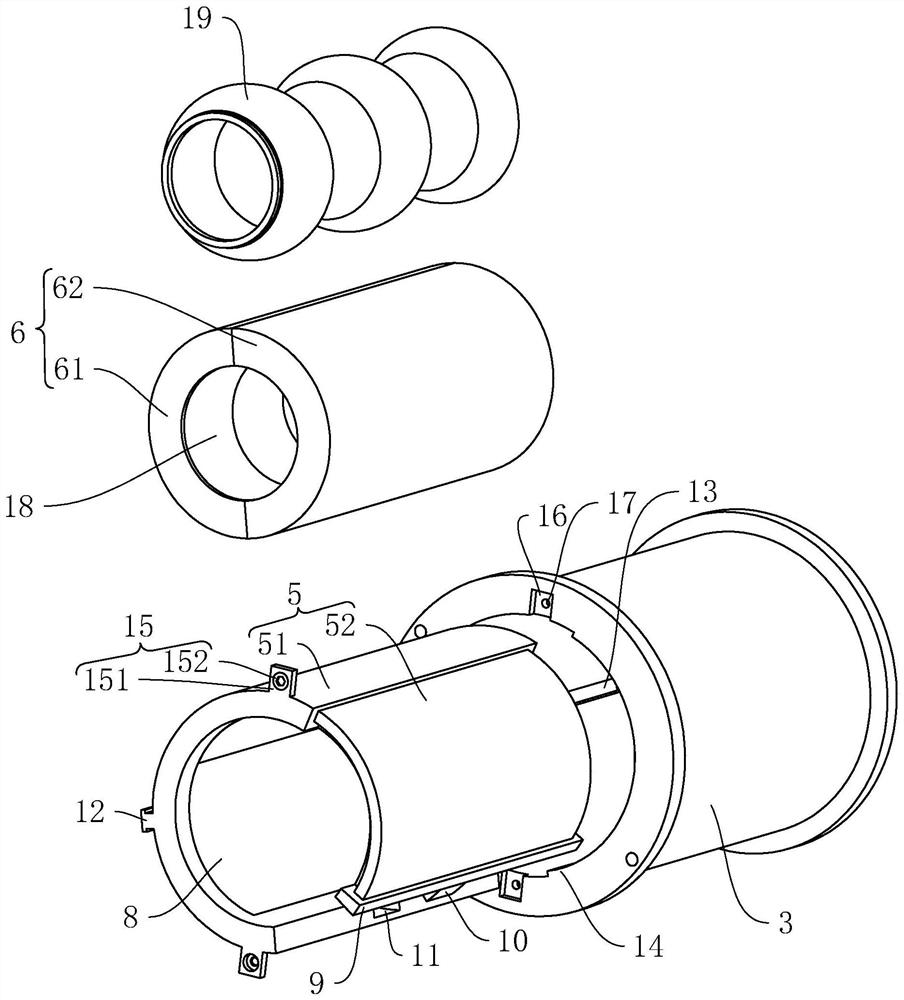

[0033] Attached to the following Figure 1-3 This application will be described in further detail.

[0034] The embodiment of the present application discloses a single screw pump.

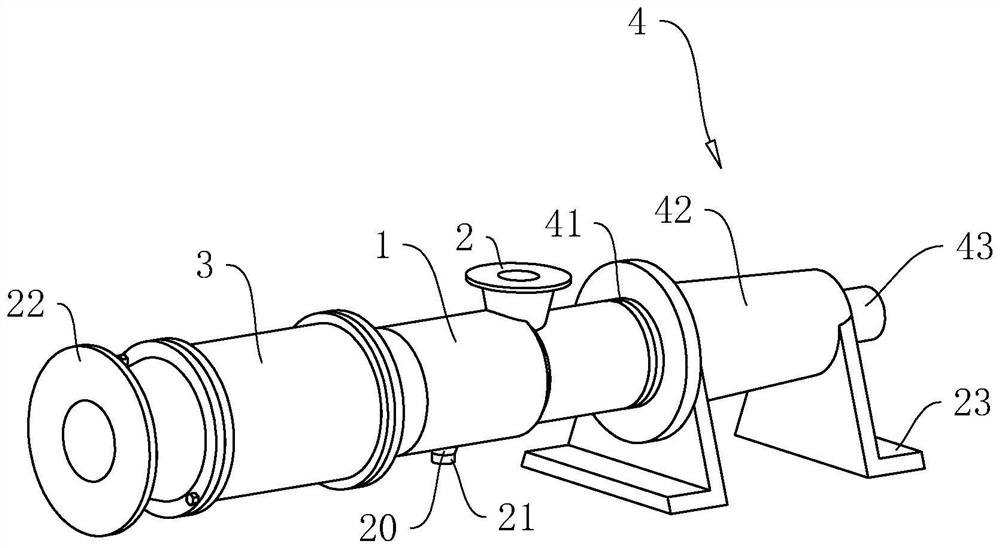

[0035] refer to figure 1 , a single-screw pump, including a suction chamber 1, a pump casing 3, a drive assembly 4 and a discharge chamber 22. The upper end of one side of the suction chamber 1 is integrally formed with a feeding port 2, and the pump casing 3 is fixed and installed on the suction chamber by bolts. The side of the material cavity 1 away from the feed port 2, the drive assembly 4 is installed on the side of the suction cavity 1 close to the feed port 2, and provides the power required for the single screw pump to work, and the discharge cavity 22 is fixed and installed by bolts On the side of the pump casing 3 away from the suction chamber 1, the medium pumped by the screw pump plays the role of guiding and discharging, which reduces the possibility of the pumping medium splashing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com