Pipe explosion simulation device based on fluid blocking test and test method thereof

A simulation device and tube squib technology, which is applied in the field of fluid blocking test, can solve problems such as difficult control of tube squib time, inability to meet millisecond-level test requirements, slow action time, etc., to achieve convenient and reliable operation, compact and reasonable structure, and precision sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

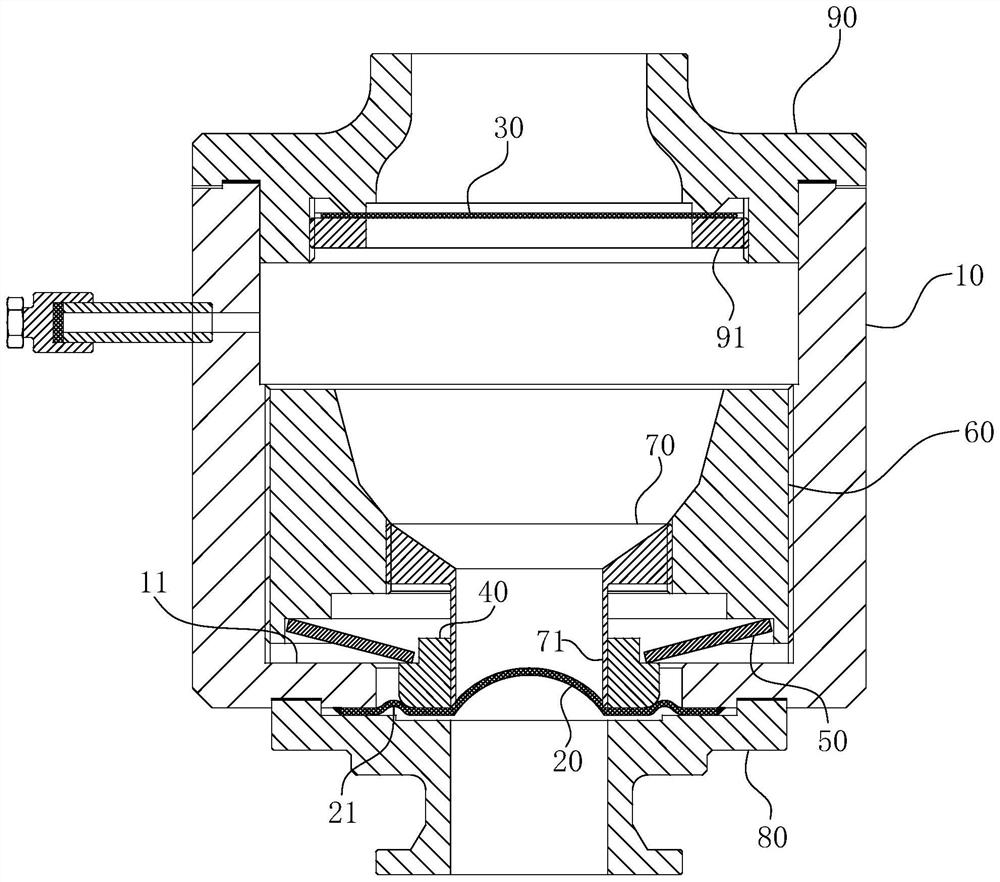

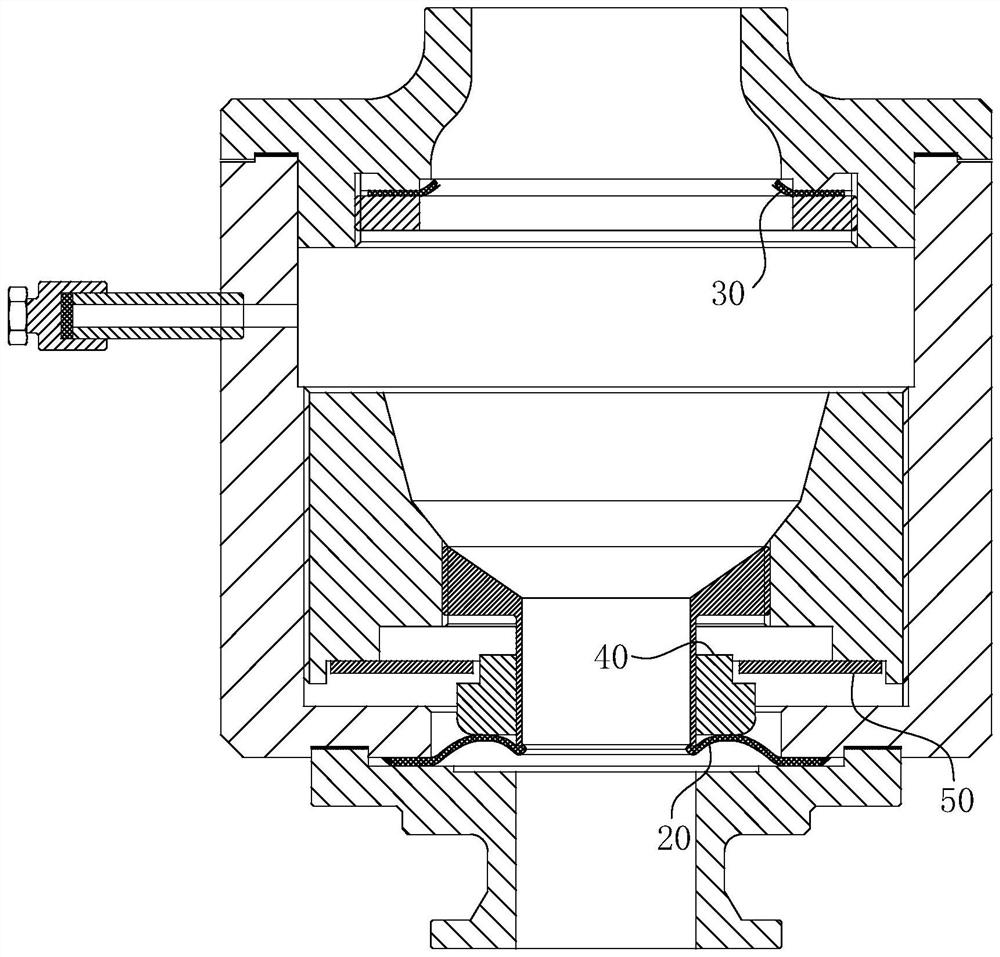

[0037] For ease of understanding, here Figure 1-6 , the concrete structure of the present invention and working mode are further described below:

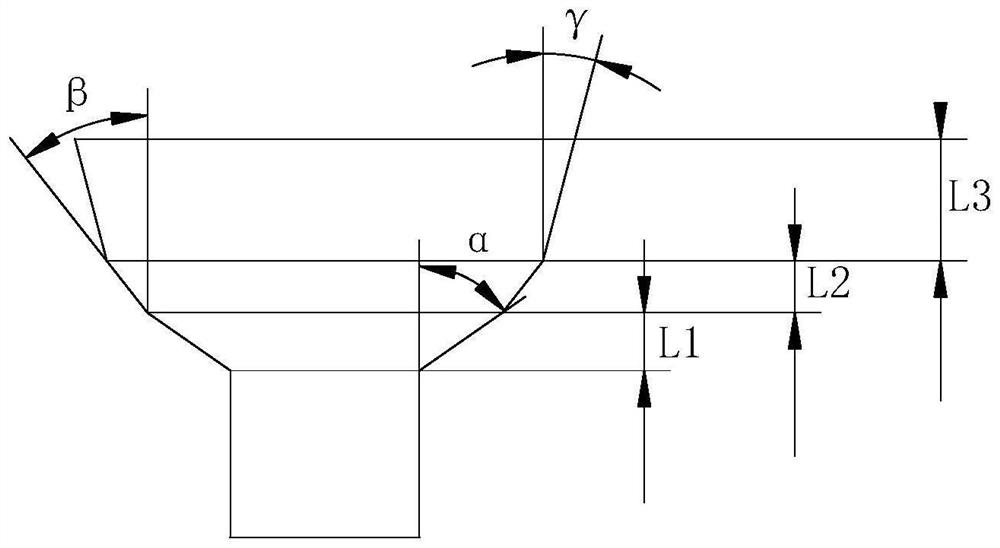

[0038] The specific structure of the present invention is as follows Figure 1-2 As shown, the outer tube body 10 is used as the carrier, and the bottom end face of the outer tube body 10 is arranged with a closing 11 to form a plunger cylinder shape as a whole, and in the cylindrical cavity of the outer tube body 10 as shown in the figure figure 1 As shown, the inlet ring cover 80, the crushing diaphragm 20, the diaphragm pressing ring 40, the disc spring 50, the diaphragm supporting ring 70 with the extension tube 71, the spring base 60, the upper pressing ring, Rupture disc 30 and outlet ring cover 90. Of course, the bursting disc 30 is used as a standard part, and the existing mature bursting disc 30 products can be reasonably selected according to the test parameters, and it is not limited to a specific structural form. in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com