Compound damping check valve fluid blocking test system and test method thereof

A test system and check valve technology, applied in mechanical valve testing and other directions, can solve the problems of high cost of the test system and the inability to truly simulate the conditions of pipeline rupture accidents, etc., to shorten the time of pipe bursting, convenient and reliable operation, and remarkable results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

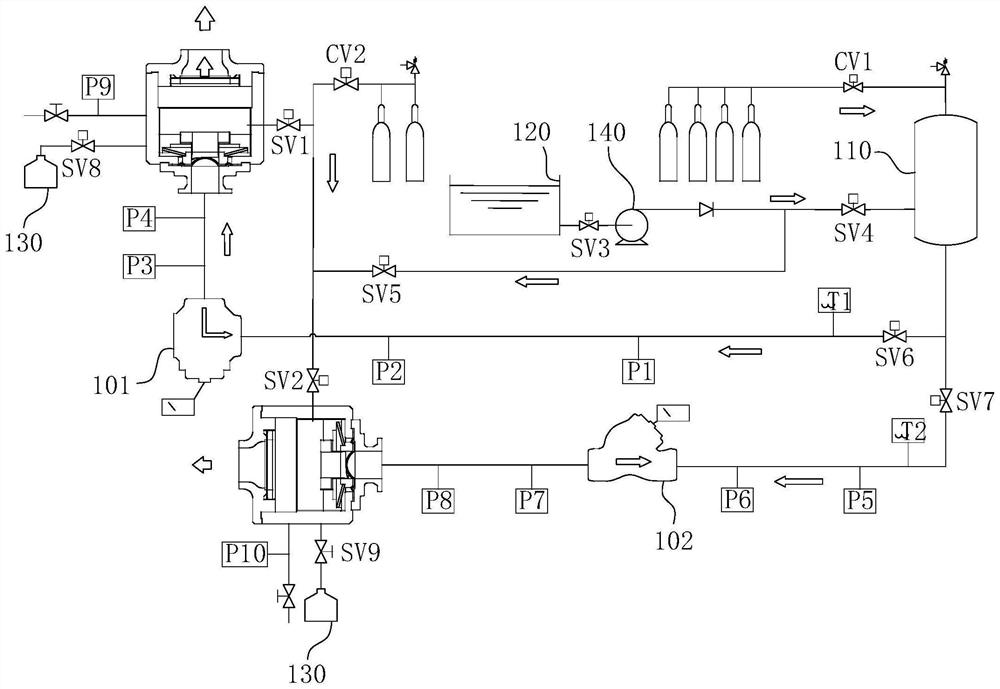

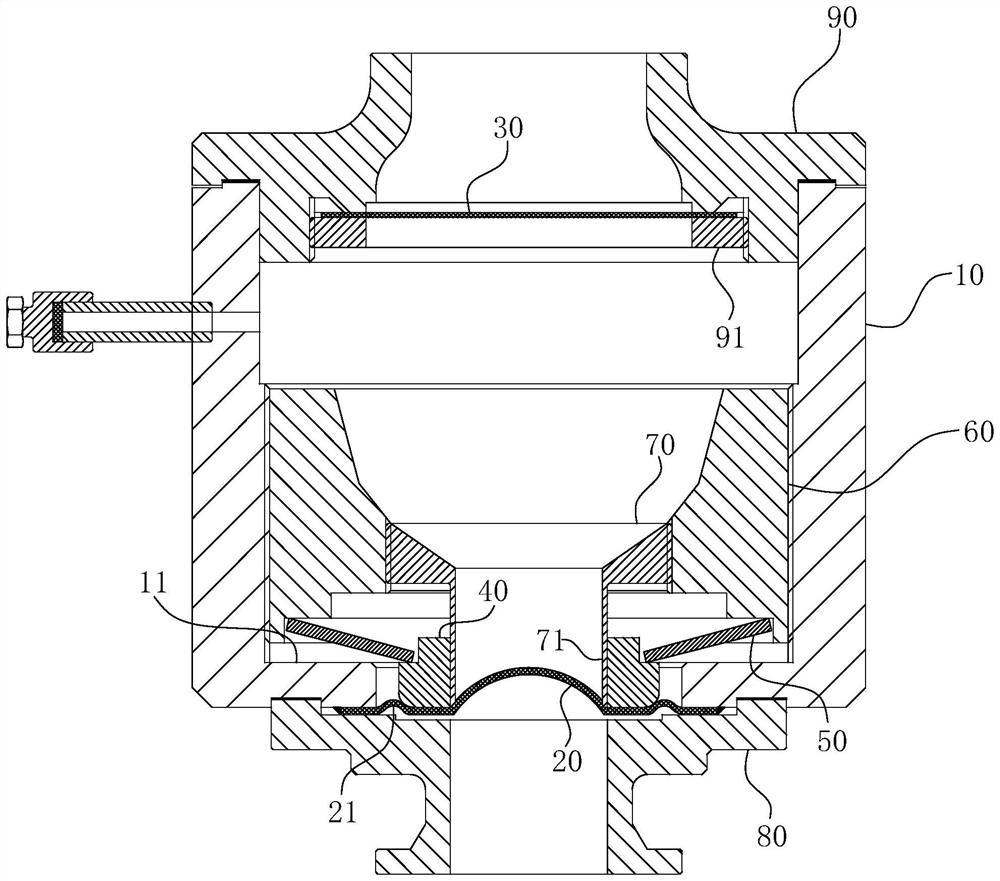

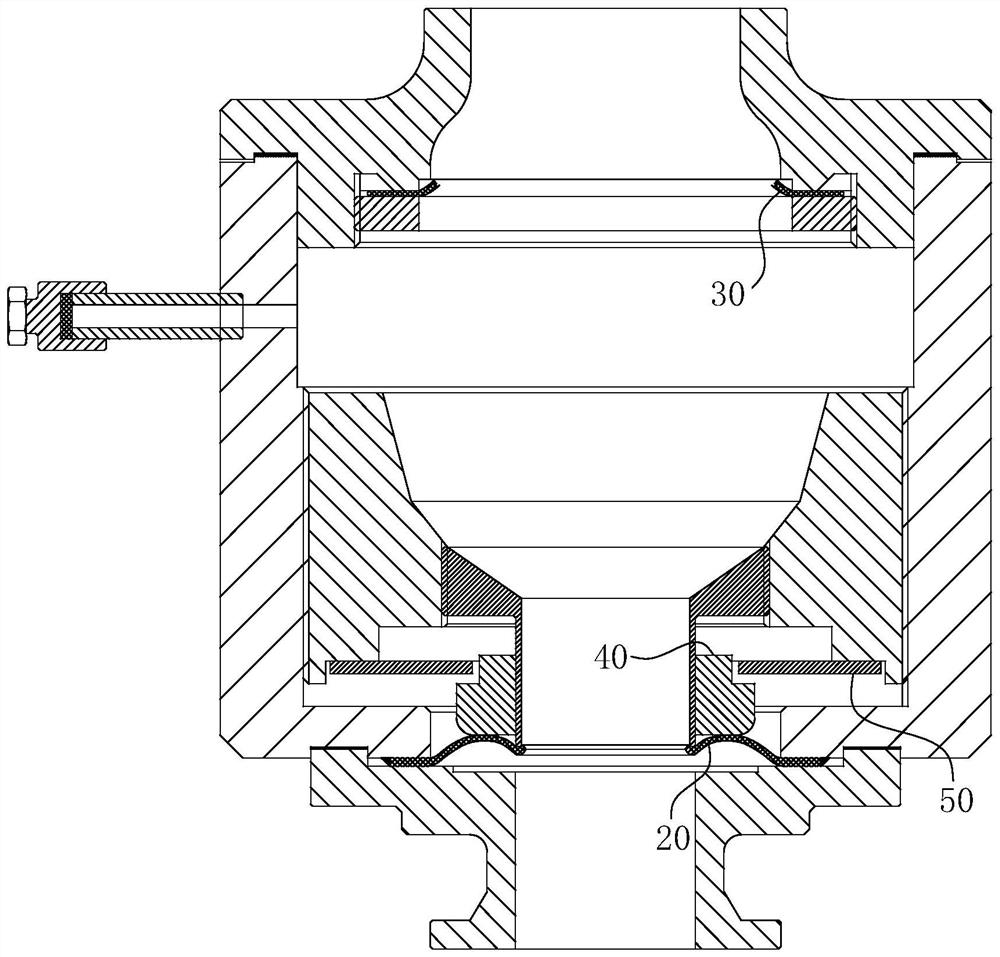

[0047] For ease of understanding, here Figure 1-7 , the concrete structure of the present invention and working mode are further described below:

[0048] When it is necessary to test the straight-through damping check valve 102 and the angle damping check valve 101 at the same time, so as to compare the working differences of the two under the same conditions, the structure of the embodiment of the present invention is as follows: figure 1 As shown, the overall system includes: a gas source composed of two high-pressure nitrogen groups, a water storage container 120, a water pump 140, an accumulator 110, the DUT, that is, a straight-through damping check valve 102 and an angle damping check valve 101. Two groups of burst pipe simulation components, sensors, data acquisition and processing systems, etc.

[0049] The gas source is composed of two groups of high-pressure nitrogen groups with different volumes. One group of high-pressure nitrogen groups provides the accumulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com