Lens module and electronic device

A technology of lens module and lens assembly, which is applied in the direction of TV, electrical components, telephone communication, etc., can solve the problems affecting the image quality, etc., and achieve the effect of improving sharpness, reducing light spots or spots, and improving image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

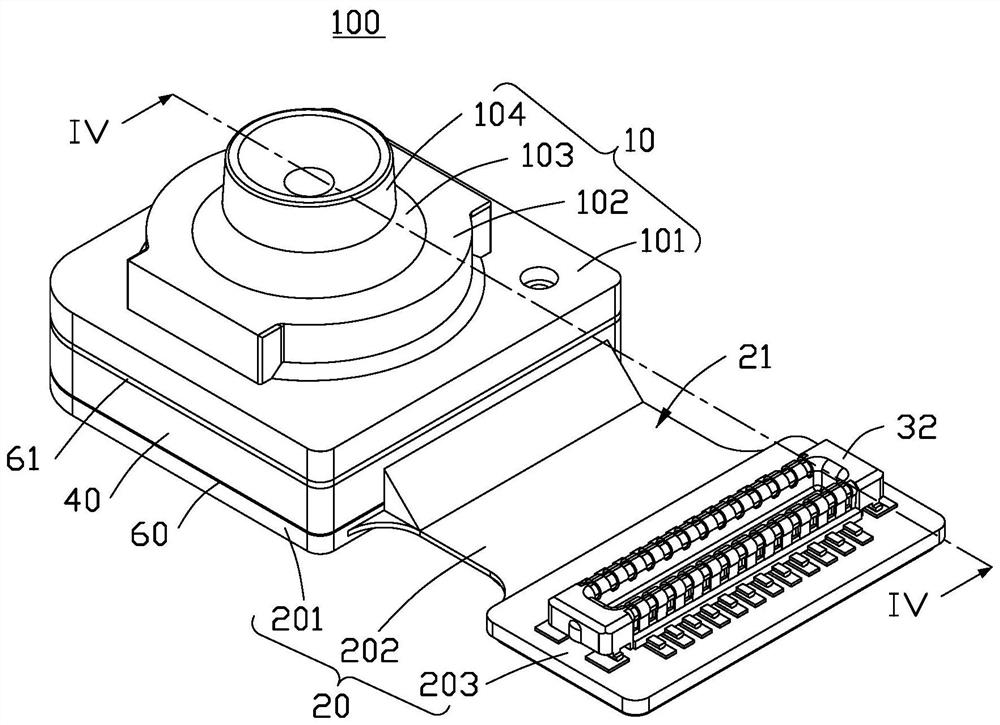

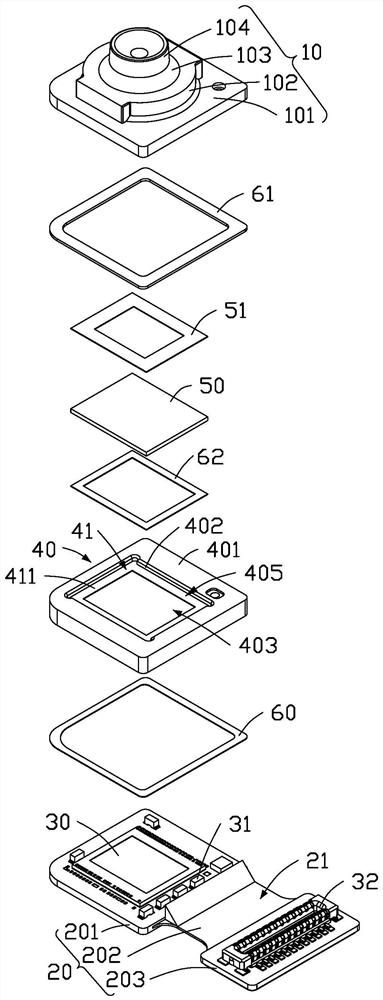

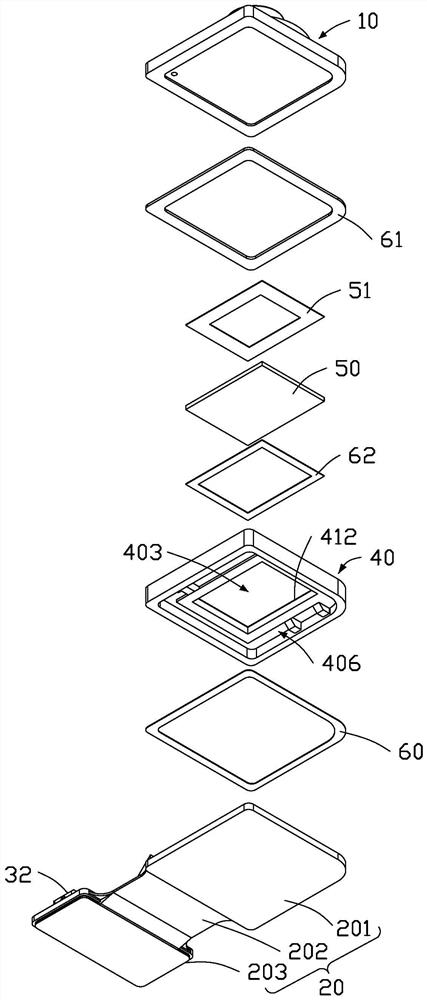

[0071] see Figure 1 to Figure 6 , a preferred embodiment of the present application provides a lens module 100, the lens module 100 includes a circuit board 20 and a lens assembly 10, the lens assembly 10 is arranged on the surface of the circuit board 20, and between the circuit board 20 and the lens assembly 10 A photosensitive chip 30 , a mounting frame 40 and a filter 50 are provided.

[0072] see figure 1 and figure 2, the circuit board 20 includes a first board part 201 , a second board part 202 and a third board part 203 , the lens assembly 10 is mounted on the first board part 201 , and the second board part 202 is connected to the first board part 201 and the third board between sections 203. The surface of the circuit board 20 facing the lens assembly 10 is the base surface 21 . The circuit board 20 can be a flexible board, a rigid board or a rigid-flex board. In this embodiment, the circuit board 20 adopts a rigid-flex board, the first board part 201 and the ...

Embodiment 2

[0087] The difference between the second embodiment and the first embodiment is the structure of the slot 404 .

[0088] see Figure 5 , the mounting bracket 40 includes a bottom surface 4041 and a side surface 4042 at the position where the slot 404 is formed, the bottom surface 4041 is connected with the inner side wall 402 , and the side surface 4042 is connected between the bottom surface 4041 and the top surface 401 . In this embodiment, the bottom surface 4041 is flat and the bottom surface 4041 is perpendicular to the side surface 4042 . The distance between the connection between the bottom surface 4041 and the inner side wall 402 and the supporting surface 411 is smaller than the distance between the surface of the filter 50 away from the circuit board 20 and the supporting surface 411 . In other embodiments, a plurality of slots 404 may also be provided between the top surface 401 and the inner side wall 402, and the plurality of slots 404 form a stepped surface, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com