Vehicle door sealing strip friction abnormal sound prediction analysis method, storage medium, equipment and device

A technology for predictive analysis and sealing strips, which is applied to measuring devices, analyzing materials, using mechanical devices, etc., can solve problems such as poor improvement effect, inability to predict and analyze the risk of friction and abnormal noise of sealing strips, and short effective time, and achieve the predicted results. Effective and achieve the effect of effective abnormal noise risk assessment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0042] The present invention provides a method, storage medium, equipment and device for predicting and analyzing the abnormal noise of friction of a door sealing strip, so as to solve the problems existing in the prior art.

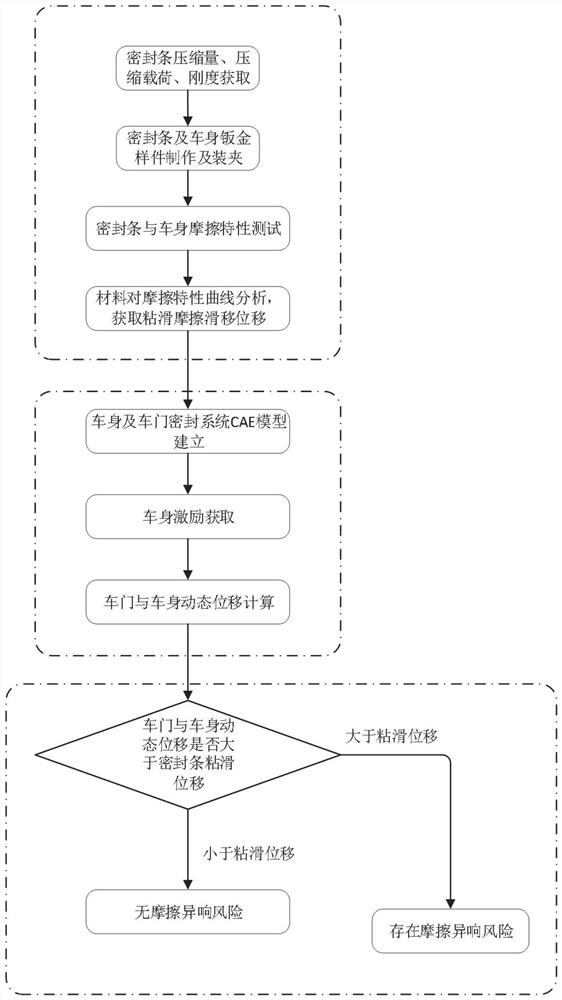

[0043] refer to figure 1 As shown, a method for predicting and analyzing the abnormal noise of friction of a door seal, the method for predicting and analyzing the abnormal noise of friction of a door seal includes the following steps:

[0044] S100. Carry out the friction characteristic test of the door sealing strip, and obtain the stick-slip slip displacement during the friction test between the door sealing strip and the painted sheet metal;

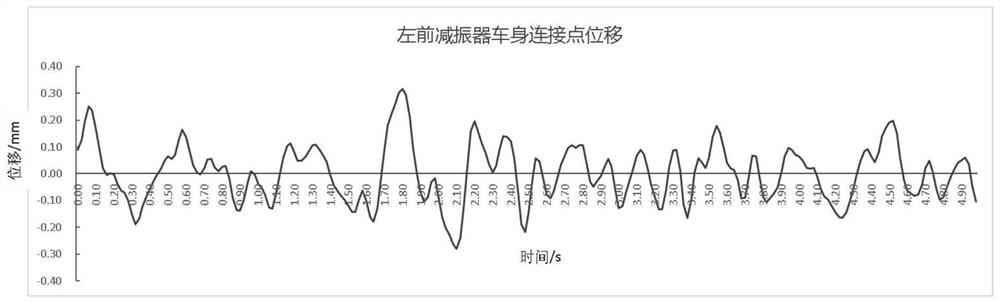

[0045] S200, performing an excitation response analysis of the body system, and calculating the relative displacement between the door and the body under excitation conditions;

[0046] S300, according to the relative displacement of the door and the body under excitation conditions and the stick-slip slip dis...

specific Embodiment 2

[0048] Further, in S100, the following steps are specifically included:

[0049] Step S110, obtaining the compression amount, compression load and stiffness information of the vehicle door sealing strip in the closed state of the vehicle door;

[0050] Step S120, prepare the test piece: the test piece includes a door sealing strip and a painted sheet metal test piece, wherein the door sealing strip is obtained by intercepting a complete door sealing strip; The surface needs to be treated to be the same as the paint finish of the whole vehicle;

[0051] Step S130, carry out the clamping and friction characteristic test of the test piece: the door sealing strip and the painted sheet metal test piece are respectively fixed on the material friction test system with clamps to ensure the contact area between the door sealing strip and the painted sheet metal test piece Matching, and the compression amount of the door seal is the same as when the door is closed; select N sliding spe...

specific Embodiment 3

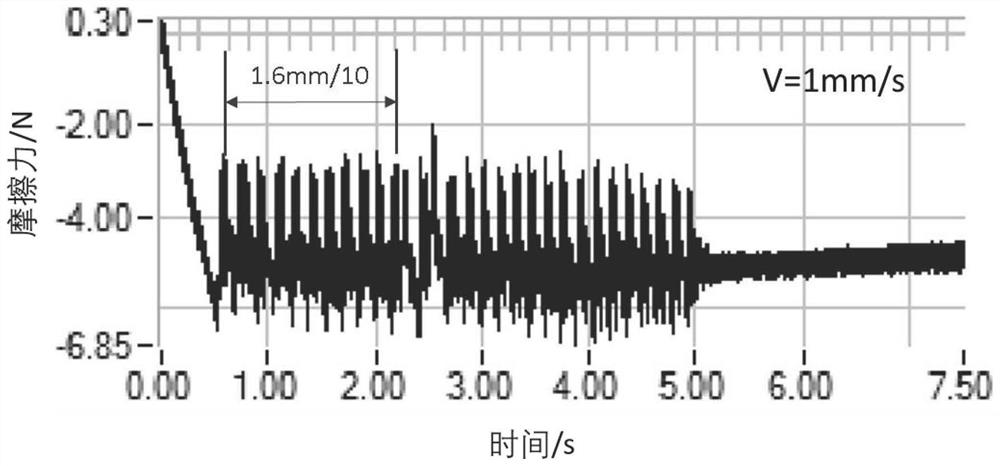

[0053] Further, in S120, specifically, the cut length of the door sealing strip is 5cm, and the surface is required to be clean and free from damage; the size of the painted sheet metal test piece is 5cm*3cm. In this embodiment, in S130, two sliding speeds are selected during the test, 1 mm / s and 3 mm / s respectively, refer to figure 2 As shown, at a speed of 1 m / s, the slip displacement when stick-slip friction occurs is 0.16 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com