Cylindrical solid-state battery and method for manufacturing same

A solid-state battery, manufacturing method technology, applied in secondary batteries, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. The content of the present invention is not limited to the description of the following embodiments. In addition, in the following embodiment, although the lithium ion battery of a solid state battery is demonstrated as an example, it can be applied to a solid state battery other than a lithium ion battery.

[0040]

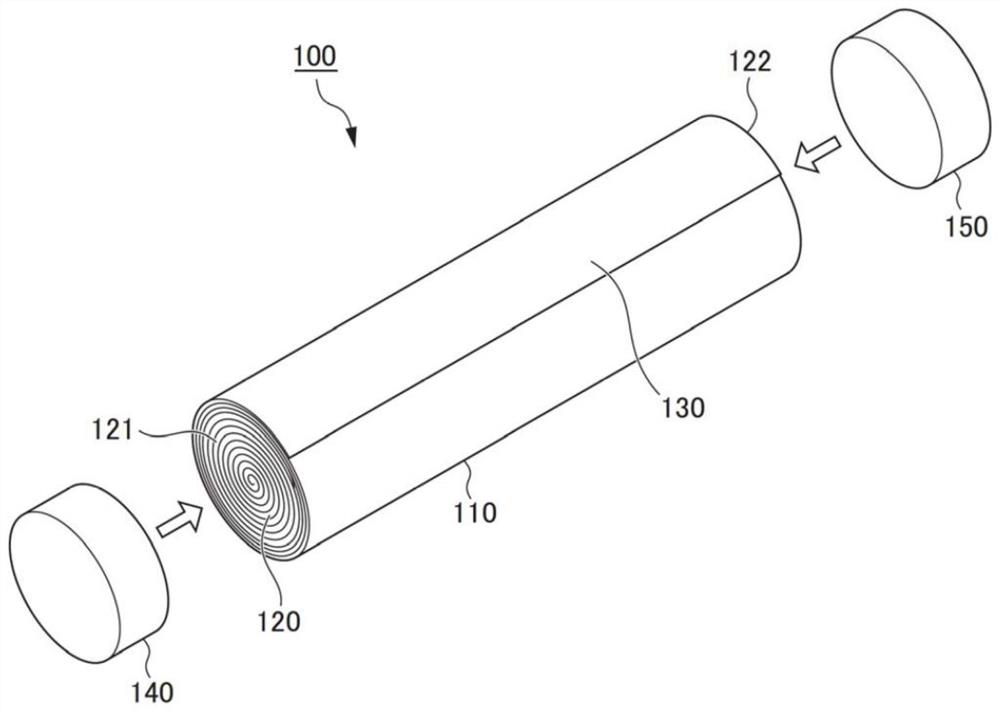

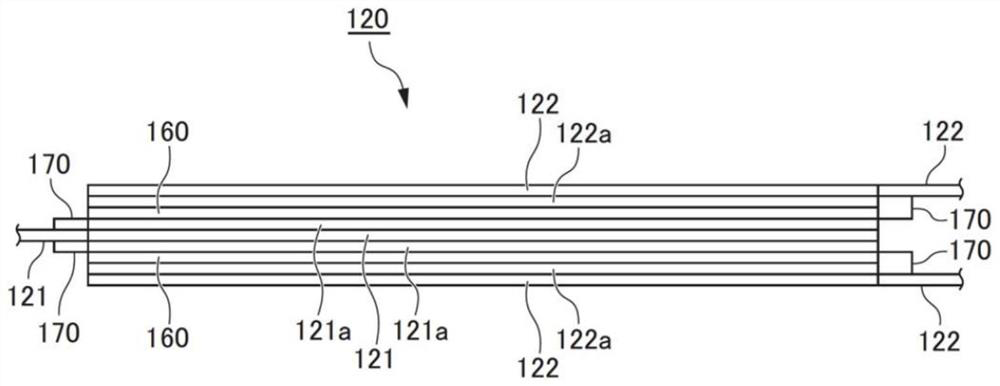

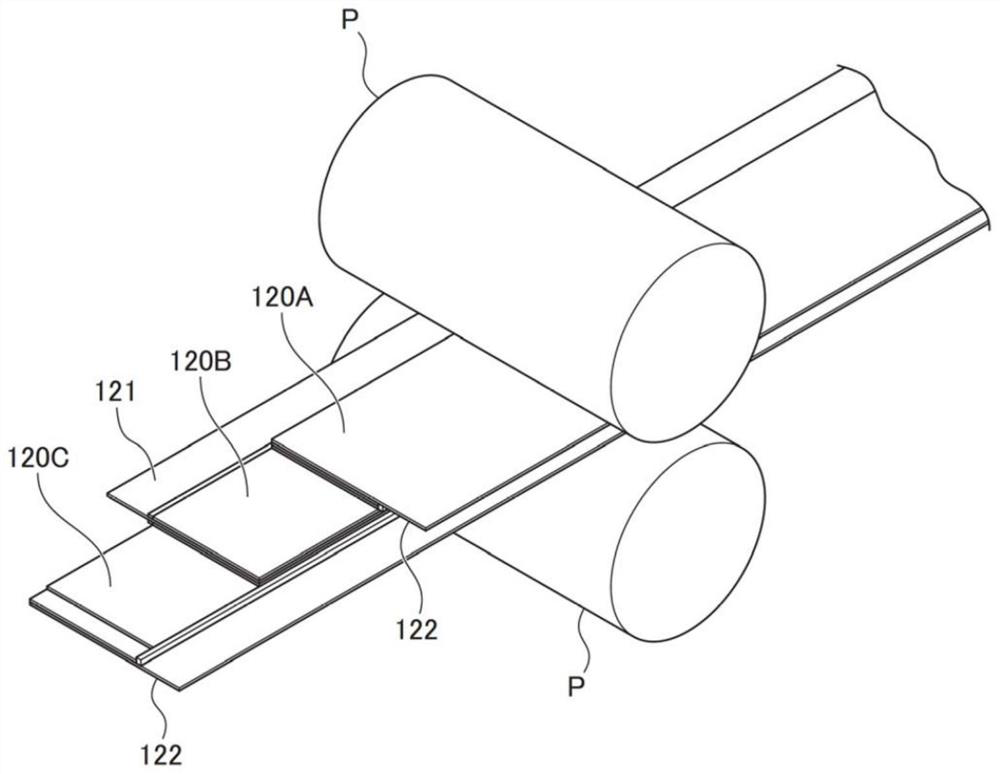

[0041] like figure 1 As shown, this embodiment of figure 1 The cylindrical solid-state battery 100 is a wound-type lithium ion secondary battery, and is composed of a cylindrical winding group 110, a negative electrode cover member 140 and a positive electrode cover member 150 electrically bonded to the upper surface and the bottom surface of the winding group 110, respectively. constitute. The winding group 110 is composed of a sheet-like electrode laminate 120 wound around a core material (not shown) and wound, and an outer wrapping material 130 wou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com