A rotary shaft conductive structure for a rotary welding device

A technology of conductive structure and welding device, applied in rolling contact bearings, rotating bearings, bearings, etc., can solve the problems of cable winding damage, grounded rotor stuck, unable to rotate, etc., to improve insulation isolation and ensure stability Contact and avoid the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

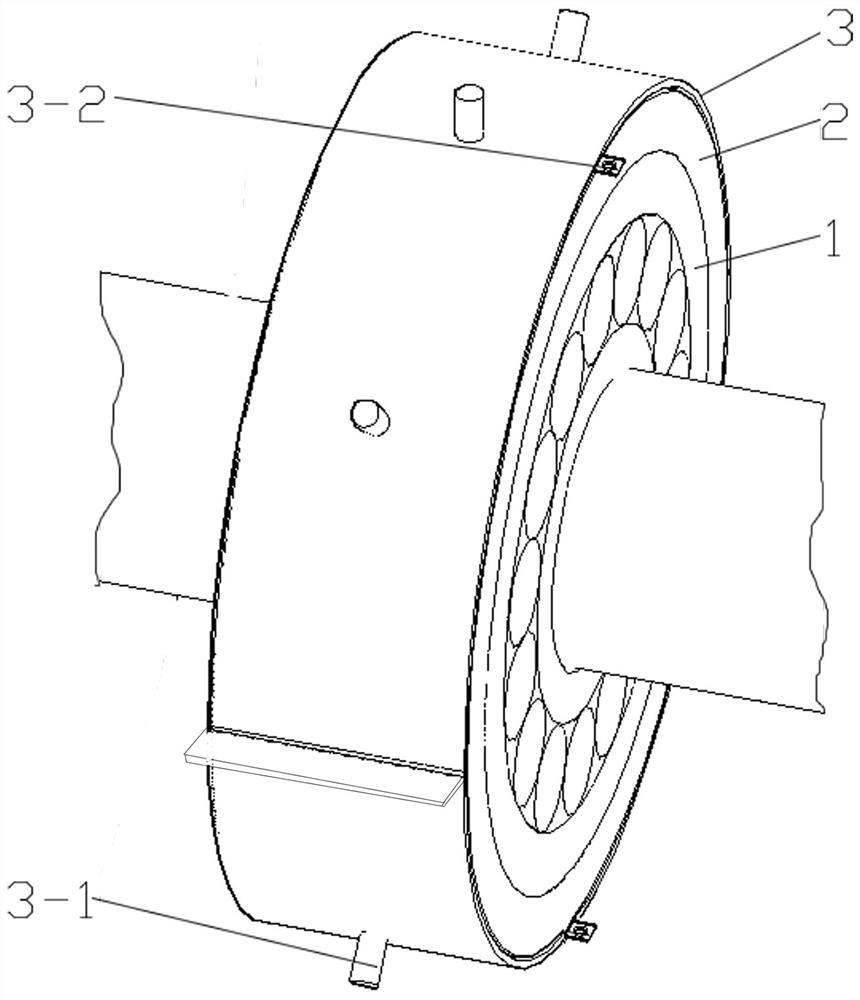

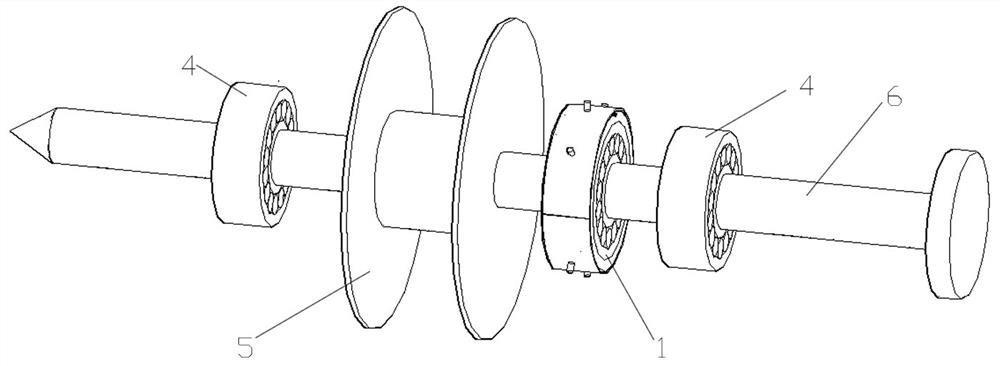

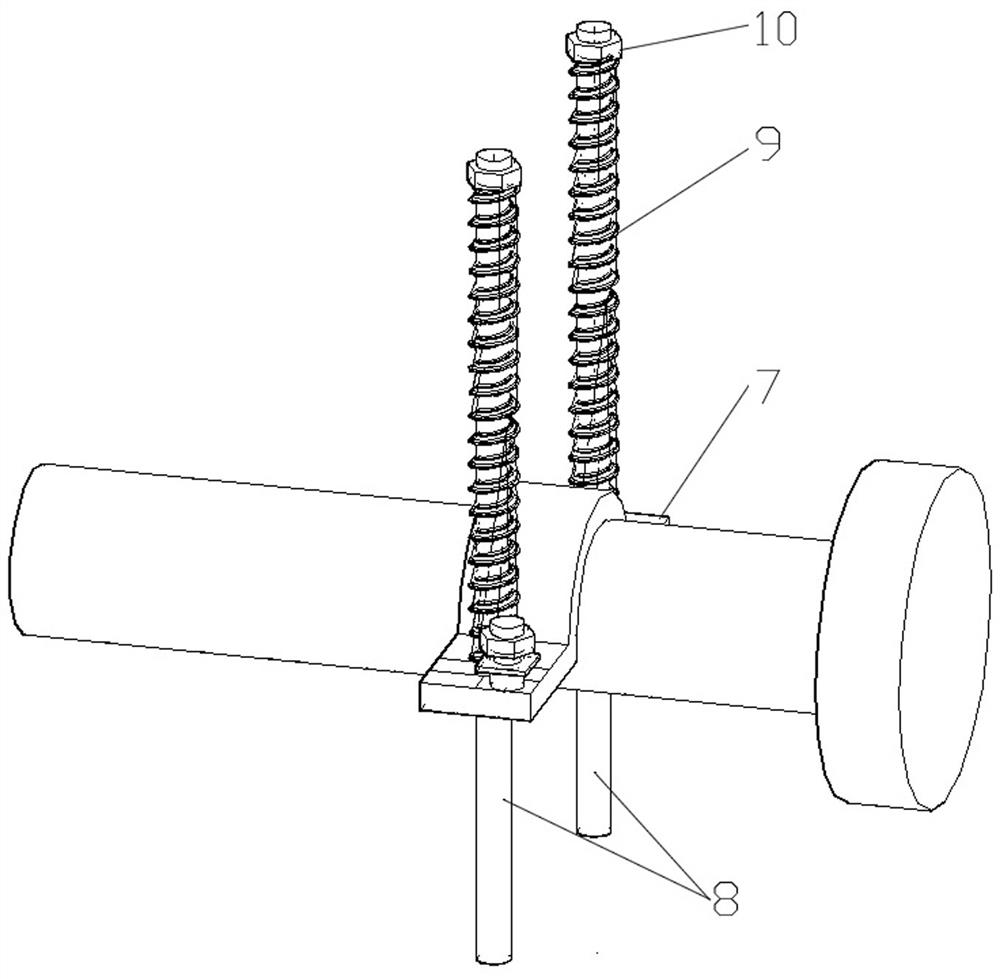

[0021] A rotary shaft conductive structure for a rotary welding device, the rotary shaft conductive structure is arranged at the rotary shaft 6 of the rotary welding device, the rotary shaft conductive structure includes a rolling bearing 1, and a conductive rubber sleeve 2 and a conductive copper sheet are arranged on the outer ring of the rolling bearing 1 3. The conductive rubber sleeve 2 is sandwiched between the outer ring of the rolling bearing 1 and the conductive copper sheet 3. The conductive copper sheet 3 is an annular structure composed of upper and lower semi-circular arc sheets. The conductive copper sheet 3 is provided with There are conductive joints 3-2, mounting holes are punched on the conductive copper sheet 3, and positioning posts 3-1 are installed at the mounting holes. The conductive rubber sleeve 2 sequentially includes a tubular material layer, an adhesive layer and a metal layer from the inside to the outside. In the mesh layer, metal powder is distri...

Embodiment 1

[0030] A rotary shaft conductive structure for a rotary welding device, the rotary shaft conductive structure is arranged at the rotary shaft 6 of the rotary welding device, the rotary shaft conductive structure includes a rolling bearing 1, and a conductive rubber sleeve 2 and a conductive copper sheet are arranged on the outer ring of the rolling bearing 1 3. The conductive rubber sleeve 2 is sandwiched between the outer ring of the rolling bearing 1 and the conductive copper sheet 3. The conductive copper sheet 3 is an annular structure composed of upper and lower semi-circular arc sheets. The conductive copper sheet 3 is provided with There are conductive joints 3-2, mounting holes are punched on the conductive copper sheet 3, and positioning posts 3-1 are installed at the mounting holes. The conductive rubber sleeve 2 sequentially includes a tubular material layer, an adhesive layer and a metal layer from the inside to the outside. In the mesh layer, metal powder is distri...

Embodiment 2

[0034] On the basis of the first embodiment, this embodiment mainly changes the formula of the conductive rubber sleeve 2 and the specific parameters of the process, and the specific description is as follows:

[0035] The conductive rubber sleeve 2 is prepared by the following steps; metal powder and additives are put into a mixer according to a set ratio, and after dispersion and stirring, the conductive material is prepared; the mixed silicone rubber material is passed through an extruder It is extruded into a tubular material, wherein the extrusion pressure is 4MPA, and the extrusion temperature is 185°C; the adhesive layer raw materials are mixed and stirred according to a certain ratio, and the mixed adhesive layer silica gel raw material is uniformly coated on the obtained product in the previous step. The inner and outer surfaces of the tubular material were prepared for use; metal mesh was laid on the inner and outer surfaces of the tubular material layer obtained abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com