Non-reburning application method of fire extinguishing carbon

An application method and coal technology, applied in waste fuel, fire prevention equipment, fire rescue, etc., can solve the problems of coal reburning and high cost of fire extinguishing agent, and achieve simple production method, low production cost, and guarantee of non-resurgence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

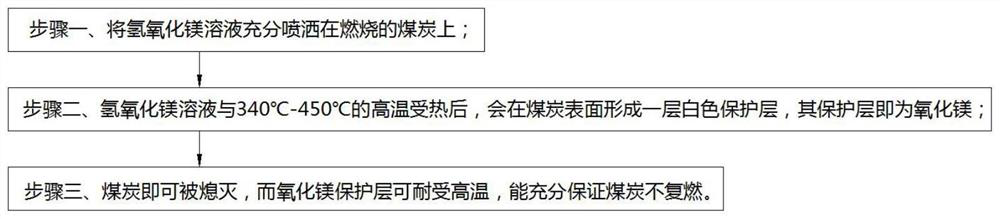

[0015] see figure 1 , the present invention provides a kind of technical scheme:

[0016] An application method for no re-ignition of fire-extinguishing charcoal, characterized in that: the specific application steps for no re-ignition of the fire-extinguishing charcoal are:

[0017] Step 1. Fully spray the magnesium hydroxide solution with a concentration higher than 5% on the burning coal;

[0018] Step 2: After the magnesium hydroxide solution is heated at a high temperature of 340°C-450°C, a white protective layer will be formed on the surface of the coal, and the protective layer is magnesium oxide;

[0019] Step 3: The coal can be extinguished, and the magnesium oxide protective layer can withstand a high temperature of 2852 ° C, which is almost impossible to reach in the daily environment, and can fully ensure that the coal does not reignite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com