Turnover horizontal type stone paint stirring machine

A mixer and stone paint technology, applied in mixer accessories, mixers, shaking/oscillating/vibrating mixers, etc., can solve the problems of inability to clean the stirring mechanism, difficult to clean the stirring mechanism, uneven mixing of real stone paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

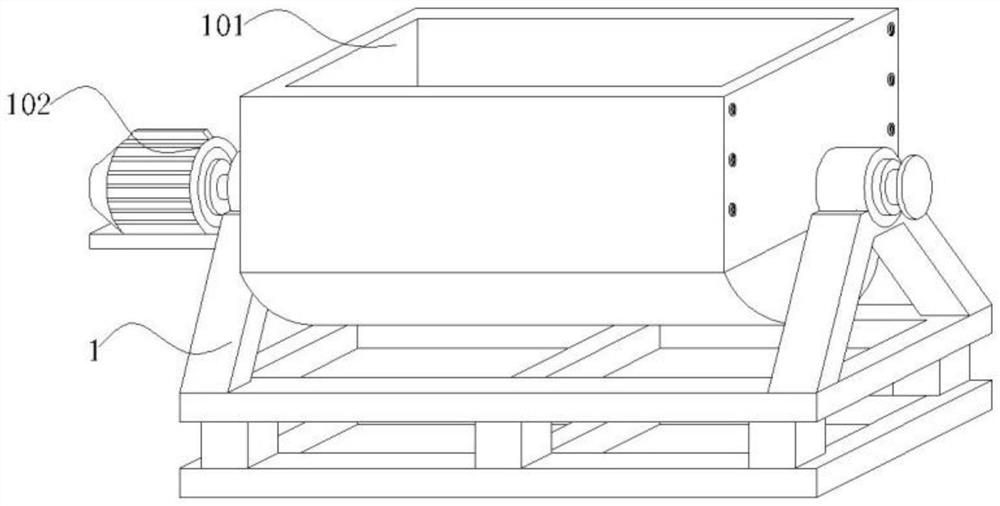

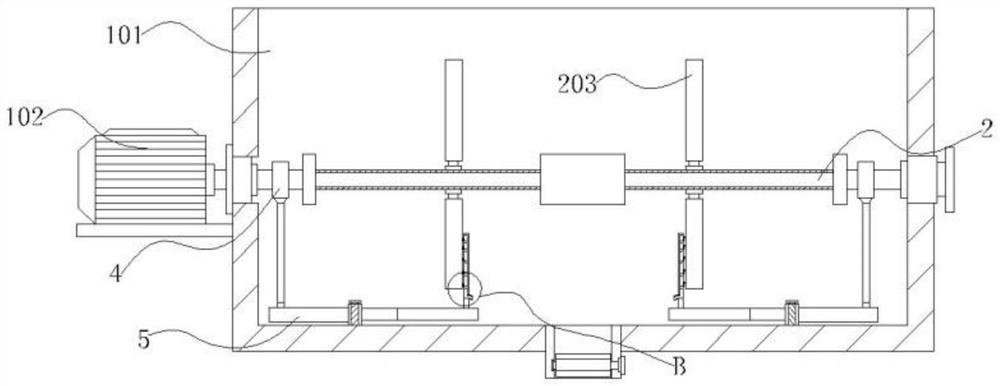

[0033] Embodiment 1: A reversible horizontal stone paint mixer, including a mixing device 1, a hopper 101 is installed on the upper end of the mixing device 1, a motor 102 is installed on one side of the hopper 101, and a side of the motor 102 close to the hopper 101 is rotatably connected with The roller shaft 202, the outer side of the roller shaft 202 slides and rotates with a stirring bracket 203, the outer side of the roller shaft 202 is provided with a transmission mechanism that can use centrifugal force to reciprocate stirring, and the two sides of the lower end of the hopper 101 are provided with inertial automatic cleaning of the stirring bracket 203. Scraping sliding mechanism;

[0034] Among them: the motor 102, the motor 102 is electrically connected with the power supply through the power cord, the side of the hopper 101 is equipped with a controller matched with the motor 102, and the roller shaft 202 rotates at a height on one side of the motor 102;

[0035] Th...

Embodiment 2

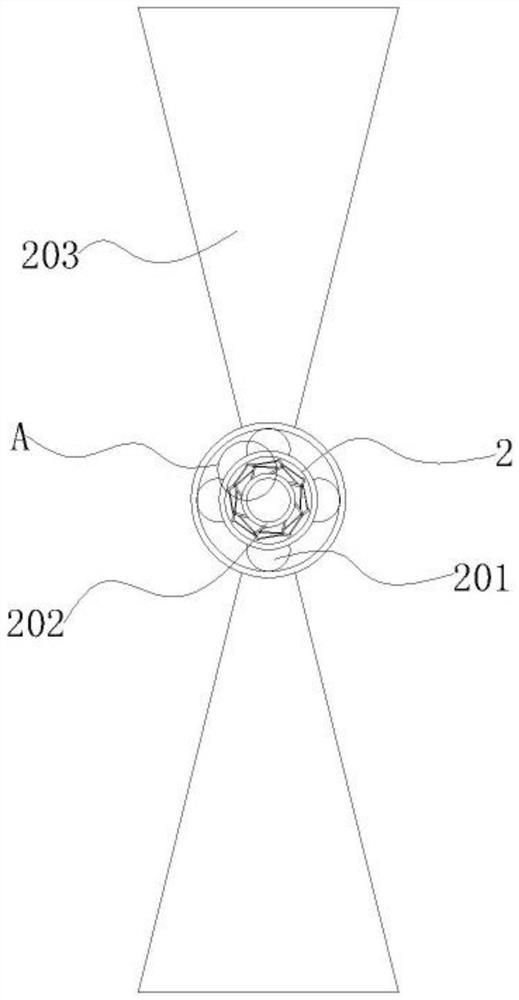

[0038] Example 2: Reference Manual Attached Figure 1-4 It can be seen that the difference between Embodiment 2 and Embodiment 1 is that the transmission mechanism includes an outer ring 2, a bump 201, a bracket 3, a rotating shaft 301, a swash plate 302 and a push rod 303, and the outer ring 2 is sleeved on the roller shaft 202. Outside, the bump 201 is embedded on the outside of the outer ring 2, the bracket 3 is embedded on the outside of the roller shaft 202, the rotating shaft 301 is hinged to one end of the support 3, the swash plate 302 swings at one end of the rotating shaft 301, and the push rod 303 is hinged to the end of the rotating shaft 301. The other side;

[0039] Wherein: the outer ring 2, the outer ring 2 penetrates and extends to the outside of the stirring support 203, the stirring support 203 slides on the outside of the outer ring 2, and the inside of the outer ring 2 is arranged in a hollow shape;

[0040] The bumps 201, the bumps 201 are arranged in a ...

Embodiment 3

[0046] Example 3: Reference Manual Attached Figure 5-7 It can be seen that the difference between Embodiment 3 and Embodiments 1 and 2 is that the sliding mechanism includes a collar 4, a shaft arm 401, a swing arm 5, a rotating bearing 501, a swing frame 502, a sliding rod 503, a scraper 504 and a discharge Tube 505, the collar 4 rotates on both sides of the roller shaft 202, the shaft arm 401 swings at one end of the collar 4, the swing arm 5, the rotating bearing 501 and the swing frame 502 swing on both sides of the lower end of the stirring device 1 in turn, and the sliding rod 503 slides on the upper end of the swing frame 502, the scraper 504 is embedded in the inner side of the sliding rod 503, and the discharge pipe 505 runs through one side of the sliding rod 503;

[0047] Wherein: the collar 4 and the axle arm 401, the end of the axle arm 401 away from the collar 4 is inclined 25-45°, and the end of the axle arm 401 away from the collar 4 is rotated and fitted with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com