Dust escape prevention device and discharging equipment comprising same

A fugitive and dust-proof technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of generality, poor applicability, backward methods, and unsolved dust, so as to prevent unloading dust pollution , Good product applicability and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is further described below with reference to specific embodiments and accompanying drawings.

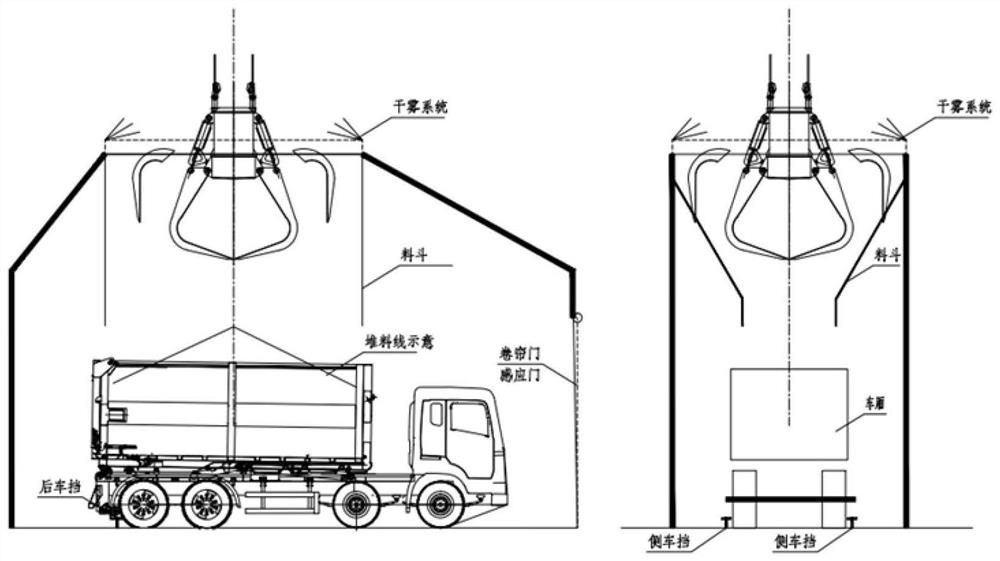

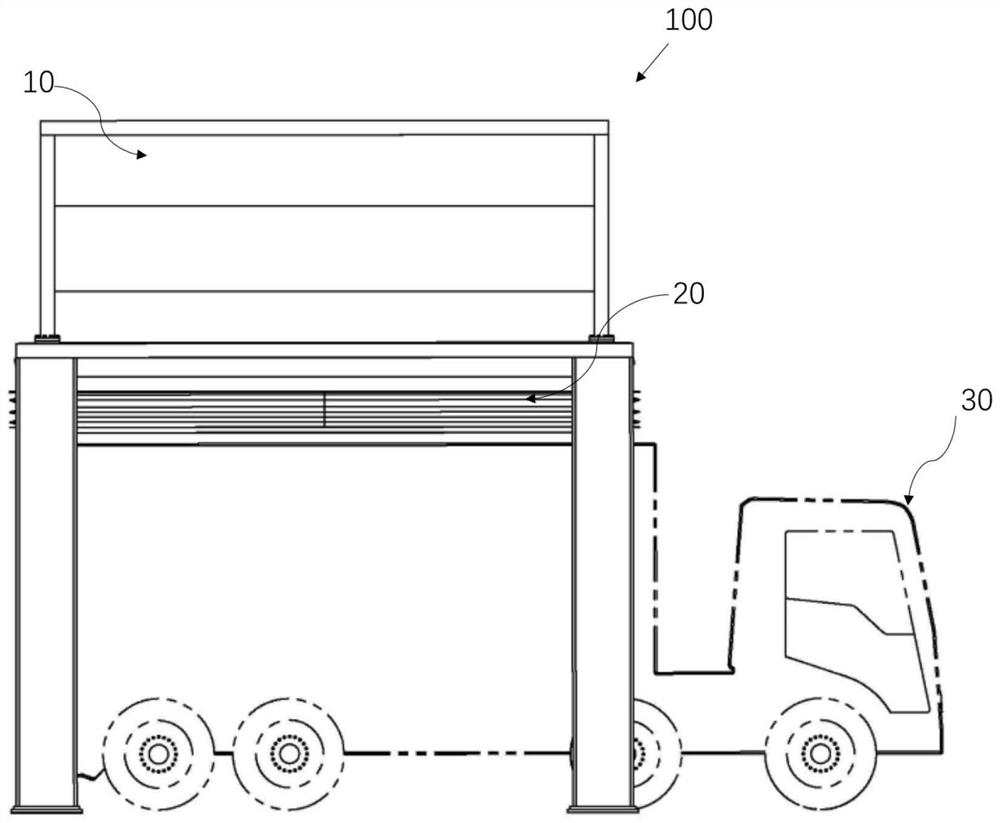

[0044] figure 2 It is a side view of the unloading equipment scene to be used involved in the embodiment;

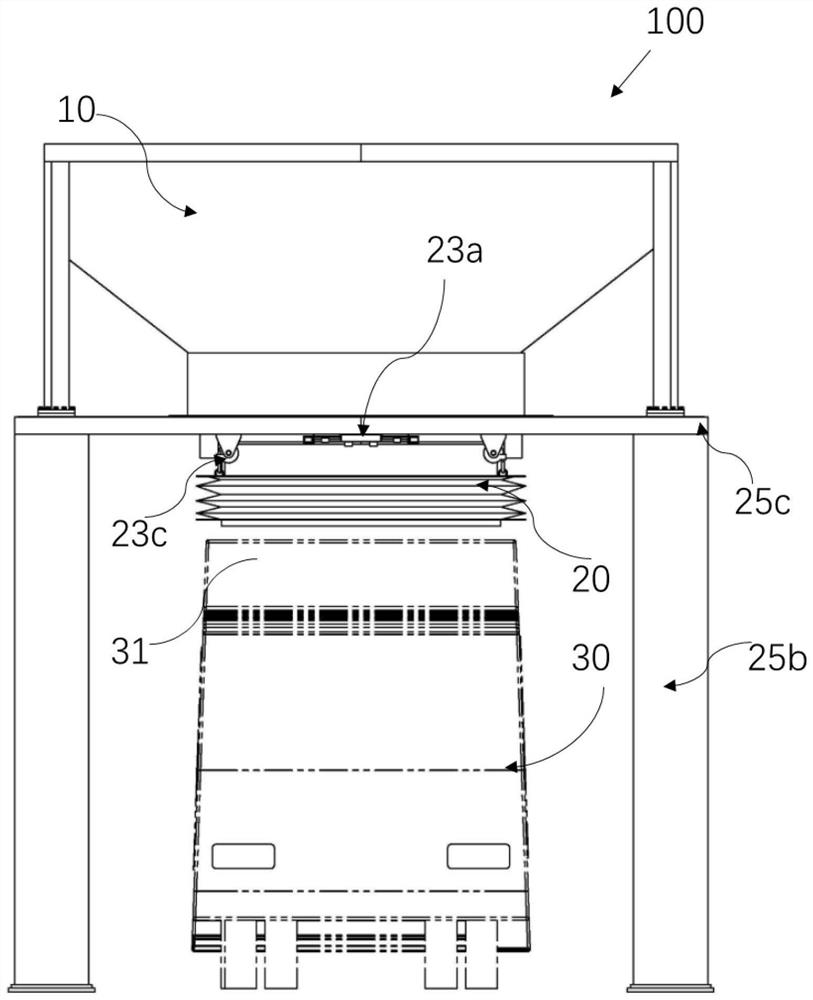

[0045] image 3 for figure 2 front view.

[0046] like figure 2 and image 3 As shown, the unloading apparatus 100 includes a hopper 10 and a dust escape device 20 . The hopper 10 is used to allow the material to pass through for unloading, and the anti-dust device 20 prevents the material from being unloaded through the hopper 10 to the receiving space 31 (that is, the moving tool 30 (that is, the transport vehicle in the figure)) that is used to transport the material. fugitive dust pollution caused by A specific description will be given below.

[0047] Figure 4 for figure 2 sectional view;

[0048] Figure 5 for image 3 sectional view;

[0049] Image 6 for Figure 4 Enlarged view of I.

[0050] like Figure 4-Figure 6 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com