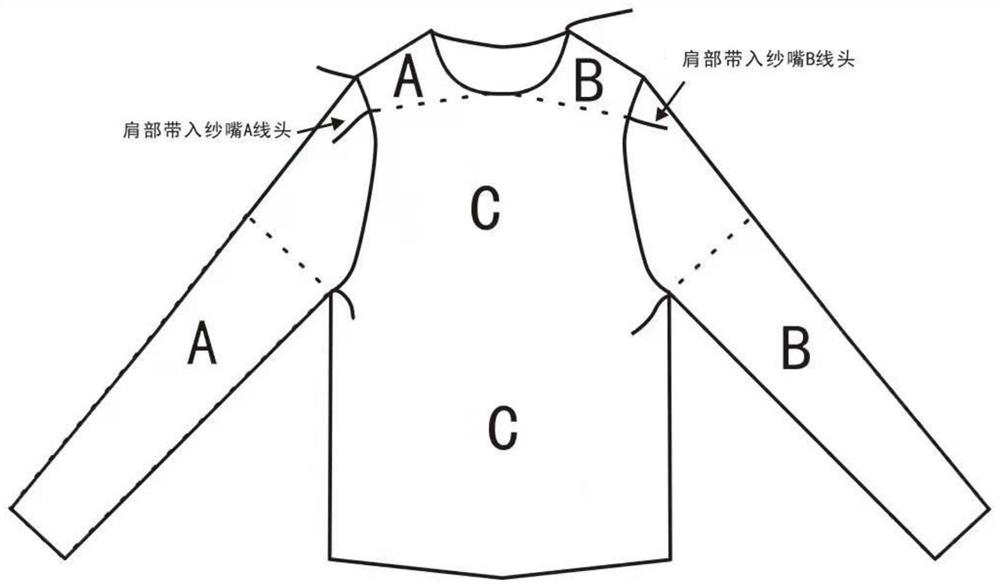

Knitting method for yarn nozzle thread end bringing-in structure on right shoulder of fully-formed square-shoulder round-collar garment

A fully formed and yarn feeder technology, which is applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of reducing production efficiency and increasing production cost, and achieve the effect of improving production efficiency, reducing production cost and broadening the development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the accompanying drawings, the present invention will be further described with respect to specific embodiments:

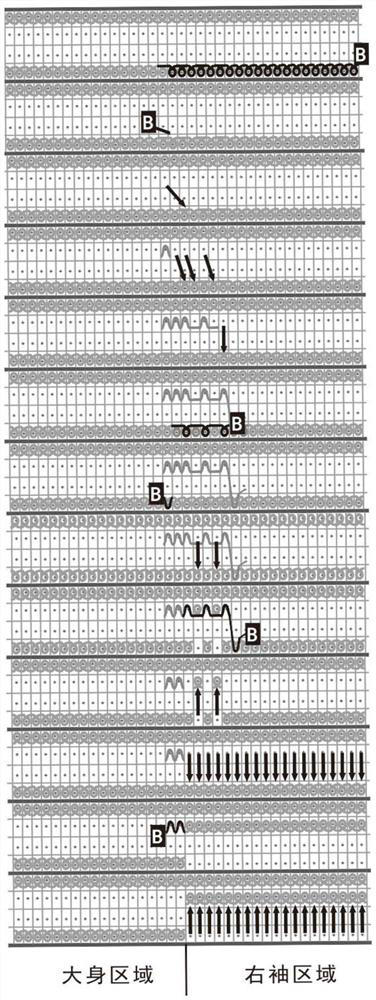

[0019] A knitting method of a yarn feeder thread end carry-in structure on the right shoulder of a fully formed flat-shoulder round neck garment. During the knitting process, when the yarn feeder B is brought in on the right shoulder, the yarn feeder B loops the junction of the right sleeve area and the body area. Transfer stitches and complete the tuck action, then turn the stitches at the junction of the right sleeve area and the body area back and wrap the yarns of the yarn feeder B brought in to achieve the effect of reinforcement.

[0020] For better expression and ease of understanding, such as figure 1 As shown in the figure, using a flat knitting machine with more than one pair of front and rear needle beds extending in the left-right direction and facing each other in the front-rear direction, the yarn feeder B of the rig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap