Gas-liquid two-phase flow pattern identification and characterization method, detection device and application

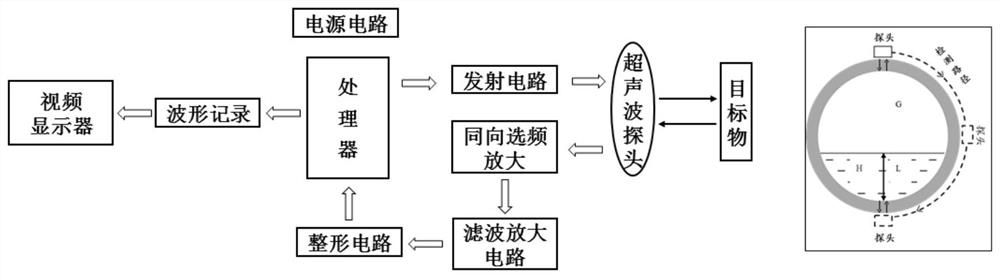

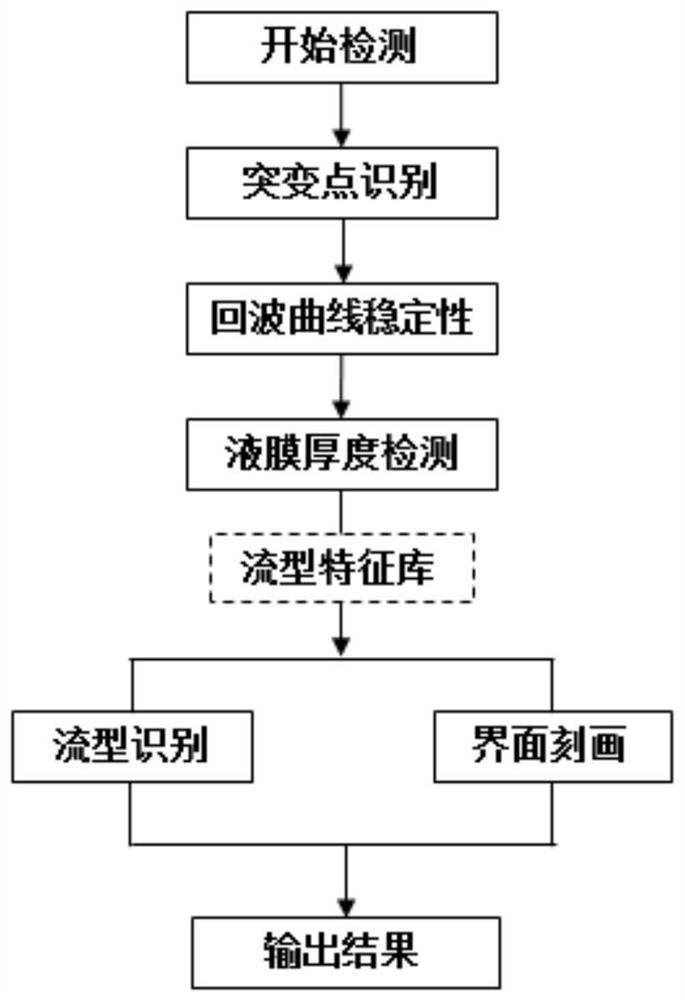

A gas-liquid two-phase flow and flow pattern identification technology, which is applied in the field of gas-liquid two-phase flow pattern identification and two-phase interface shape characterization, can solve the problems of laminar flow distinction, unresearched flow pattern interface shape, etc., and achieves wide application Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

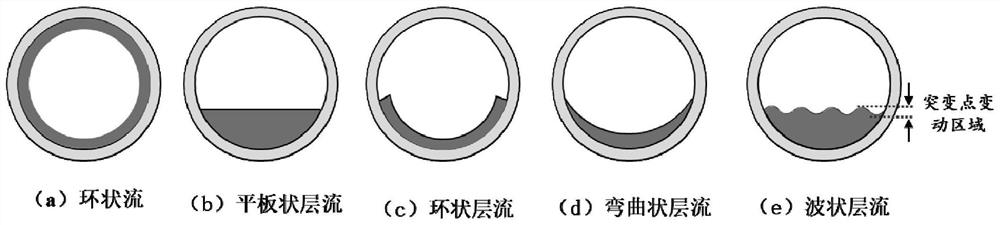

[0091] Annular laminar flow, identification method: there is no sudden change point, the entire detection area is a solid-liquid interface, the thickness of the liquid film at each position is not 0, and the echo curve does not change with time;

[0092]Interface characterization: Determine the thickness of the liquid film at 0 o'clock, 3 o'clock, and 6 o'clock respectively, and then connect the three points to determine the shape of the right half of the interface. The interface shape is as attached. figure 2 (a);

Embodiment 2

[0094] Flat laminar flow, identification method: there is a sudden change point, the thickness of the liquid film at the sudden change point is 0, at the same time, the height of the sudden change point position is equal to the liquid film thickness at 6 o'clock, and the echo curve is stable;

[0095] Interface characterization: Determine the sudden change point and the thickness of the liquid film at 6 o'clock respectively, and then connect the two points to determine the shape of the interface in the right half. attached figure 2 (b).

Embodiment 3

[0097] Annular laminar flow, identification method: there is a sudden change point, the thickness of the liquid film at the sudden change point is not 0, and the thickness of the liquid film at the sudden change point is equal to the thickness of the liquid film at the 6 o'clock position, and the echo curve is stable;

[0098] Interface characterization: Determine the thickness of the liquid film at 0 o'clock, 3 o'clock, and 6 o'clock, respectively, and then connect the three points to determine the shape of the interface in the right half, and the left half is symmetrical according to the connection line between 0 o'clock and 6 o'clock The principle is complete, and the interface shape is as attached figure 2 (c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com