Detachable formwork for wall expansion joint of shear wall structure

A technology for dismantling formwork and shear walls, which is applied in the field of formwork/formwork/work frame, preparation of building components on site, and connection parts of formwork/formwork/work frame, etc., which can solve the inconvenience of disassembly and poor quality of pouring Control and other issues to achieve the effect of easy operation, perfect support and high pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

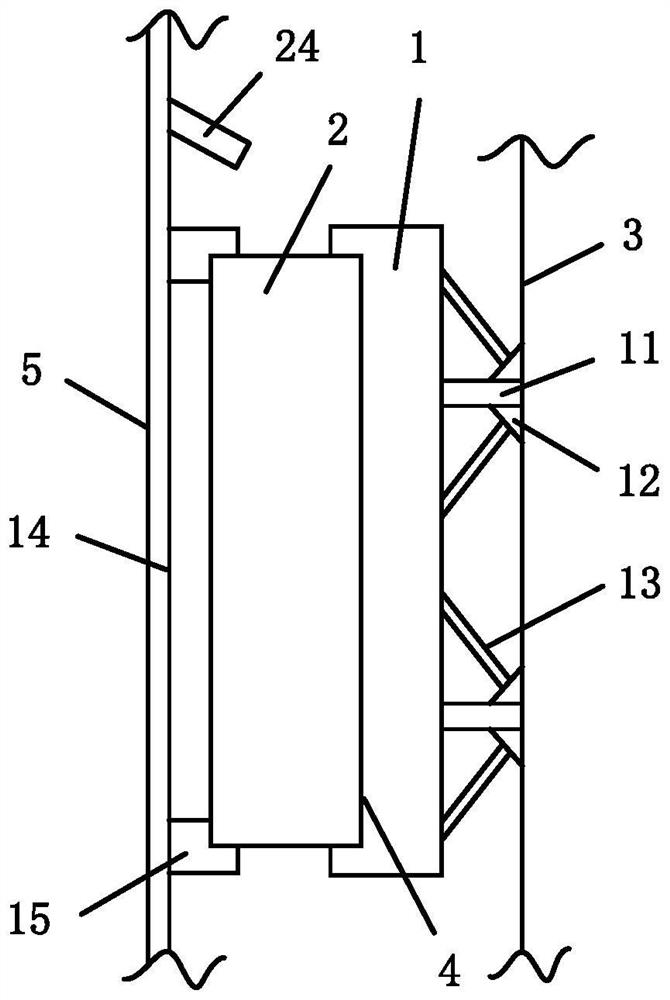

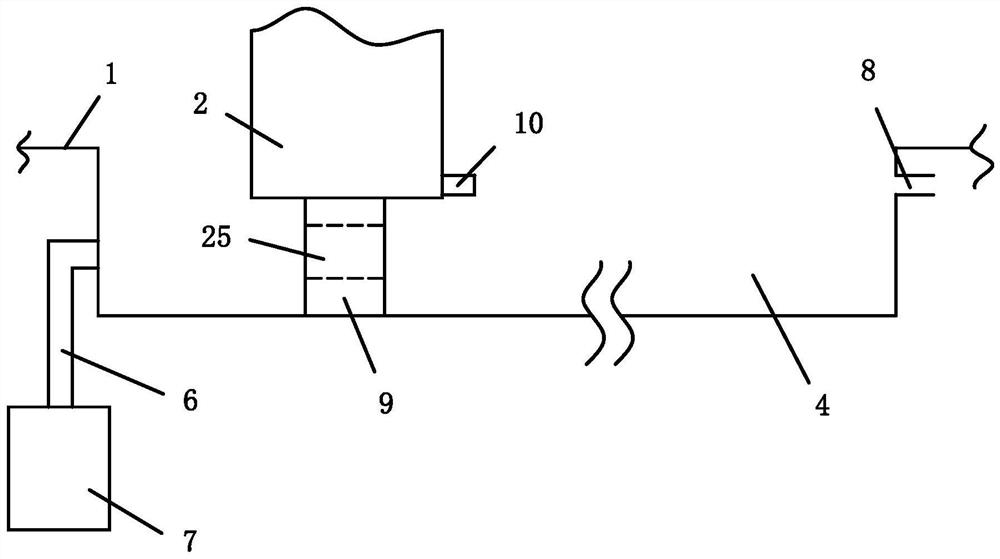

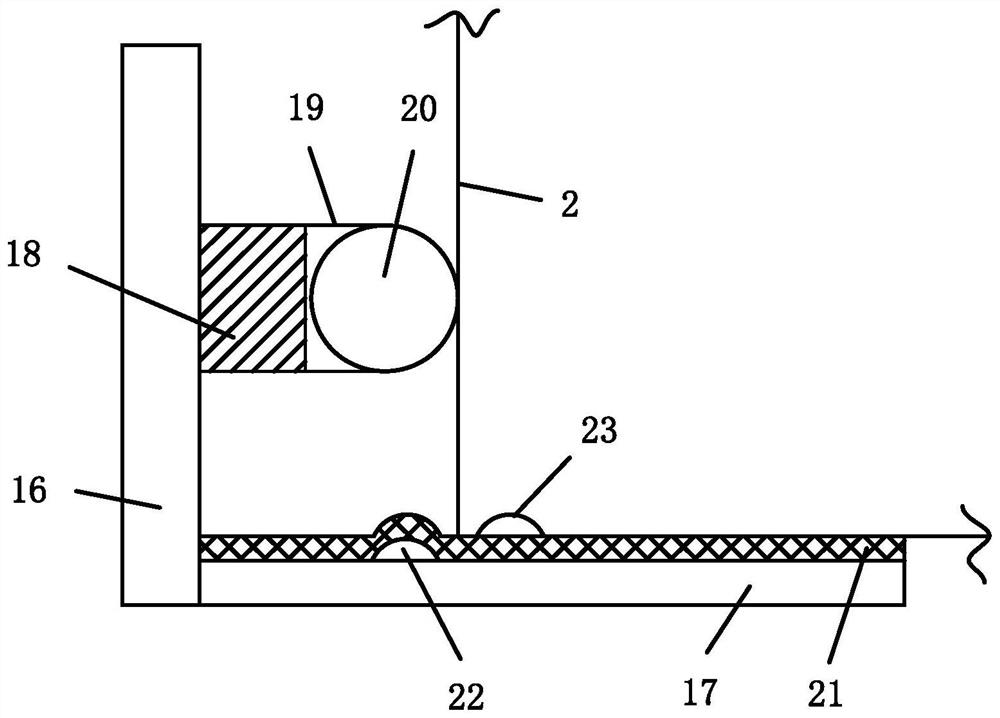

[0016] refer to Figure 1-3 , a specific embodiment of the present invention includes an inner template 1 and an outer template 2, the inner template 1 is fixed on the wall support 3, the surface of the inner template 1 is provided with a chute 4, and the outer template 2 is slidably inserted in the chute 4 On the outside of the outer formwork 2, a formwork support 5 is installed, and the external formwork 2 is in sliding contact with the formwork support 5. One end of the chute 4 is connected to the air compressor 7 through the compressed air pipeline 6, and the other end of the chute 4 is provided with a discharger. The air hole 8, the part of the outer template 2 located in the chute 4 is provided with a number of guide plates 9 parallel to each other, and the end of the outer template 2 facing the exhaust hole 8 is fixed with a sealing plug that matches the exhaust hole 8 10. The wall support 3 is connected with the inner formwork 1 through the fastening screw 11 . A tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com