Liquid rocket engine test run diaphragm box type end face sealing fault monitoring method

A liquid rocket and end face sealing technology, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as propellant leakage, less end face sealing structure, and impact on engine work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below with reference to the accompanying drawings.

[0046] The invention provides a liquid rocket engine bellows-type end-face seal fault monitoring method, and proposes parameters to be monitored for end-face seal faults and a calculation method for monitoring parameter thresholds. It can be used to monitor the working process of liquid rocket engines to ensure product safety in the case of end face seal failures.

[0047] The steps of the present invention are as follows:

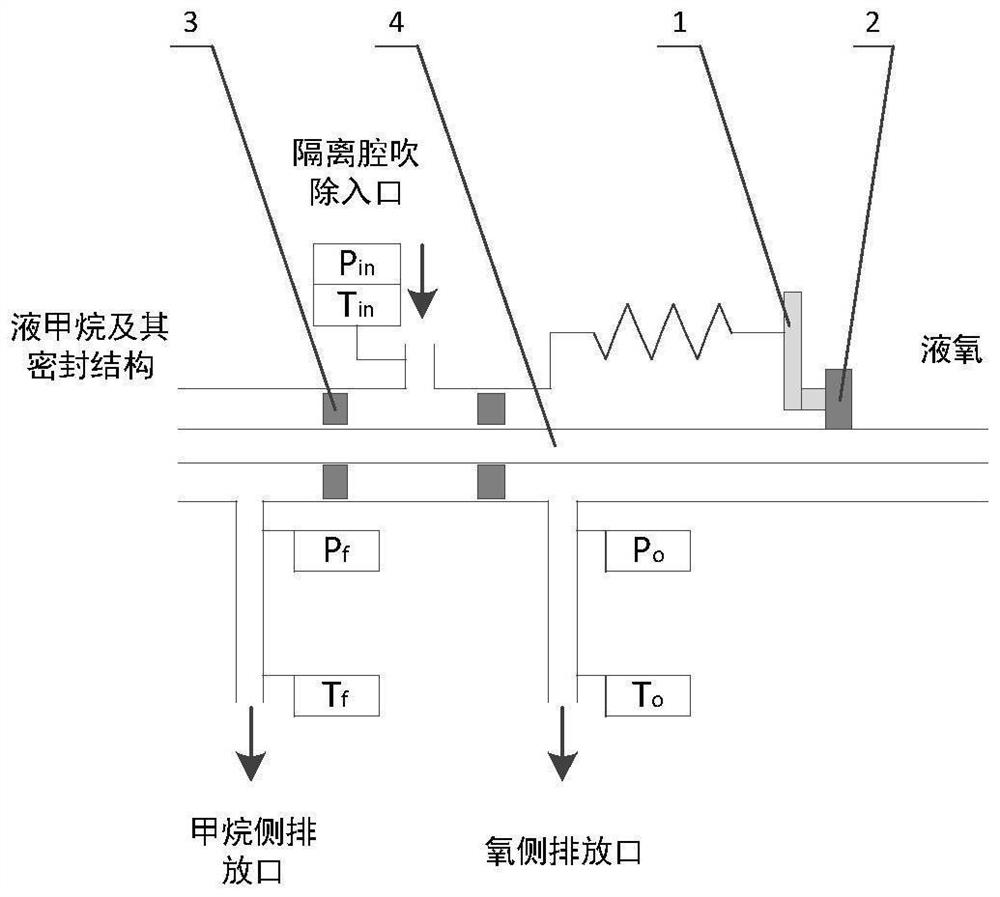

[0048] (1) Set the pressure measuring point Pin and the temperature measuring point Tin at the blow-off inlet of the isolation chamber of the liquid rocket engine, set the pressure measuring point Pf and the temperature measuring point Tf at the fuel side discharge port, and set the pressure measuring point Po at the oxidant side discharge port and temperature measuring point To.

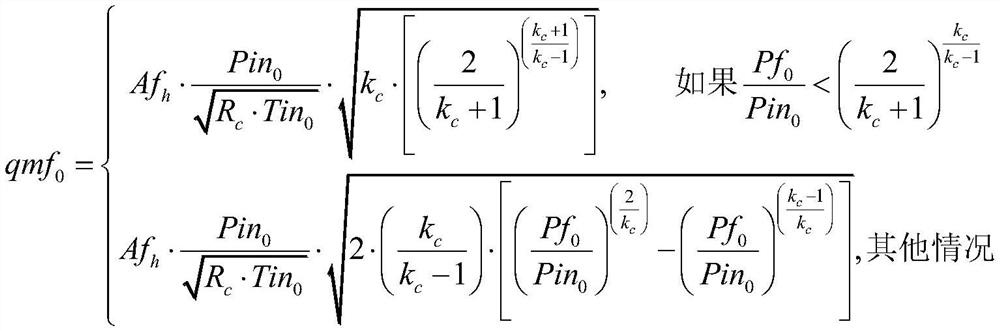

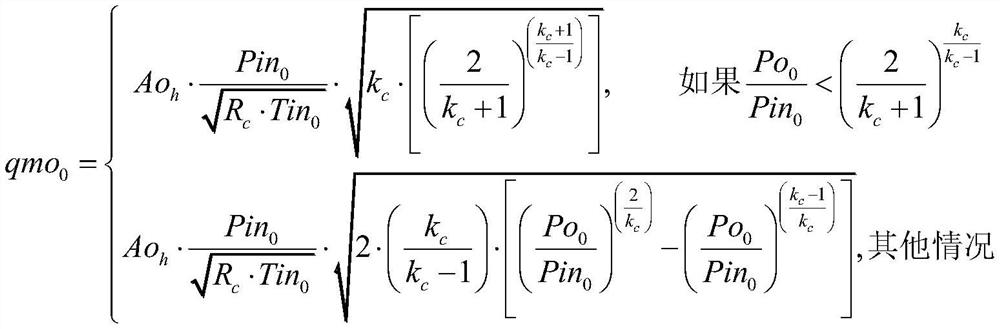

[0049] Taking the open-cycle liquid oxygen methane engine as an exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com